Synchronous nitrosation-Anammox device for low-temperature low-ammonia-nitrogen sewage based on magnetic induction heat effect and application thereof

A thermal effect, low ammonia nitrogen technology, applied in the field of sewage biological denitrification treatment, can solve the problems of low activity, increased energy consumption, unstable nitrosation process, etc., to achieve increased accumulation rate, expanded proportion, low consumption and high efficiency denitrification capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

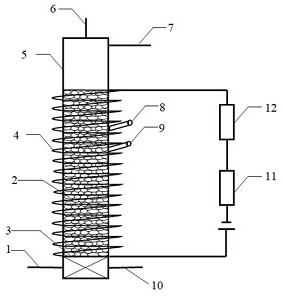

[0032] This embodiment relates to a low-temperature low-ammonia-nitrogen sewage synchronous nitrosation-Anammox device based on the magnetic induction thermal effect, and its specific structure is as follows figure 1 Shown:

[0033]It includes a sewage treatment container 5, a composite filler 2 filled in the sewage treatment container 5 and a magnetic field generating device outside the sewage treatment container 5; a water inlet 1 and an air inlet 10 are provided at the bottom of the sewage treatment container 5 , the upper part of the sewage treatment container 5 is provided with a water outlet 7 and an air outlet 6; the interior of the composite filler 2 is a metal conductor 2-1, the middle layer is a protective layer 2-2, and the outer layer is a porous adsorption carrier layer 2- 3. Anammox bacteria and nitrosative bacteria grow on the porous adsorption carrier layer 2-3 from the inside to the outside; the solenoid coil 4 is connected to the voltage regulator 11 and the ...

Embodiment 2

[0042] The specific application of the low-temperature low-ammonia-nitrogen sewage synchronous nitrosation-Anammox process based on the magneto-inductive thermal effect involved in the embodiment, the steps are as follows:

[0043] 1) Pass the sewage with ammonia nitrogen concentration of 45-50 mg / L and COD concentration of 40-50 mg / L into the sewage from the lower water inlet to control the hydraulic retention time to 2-4h until the effluent ammonia nitrogen ≥ 5mg / L, then stop the water intake , empty the sewage treatment container, and complete the initial ammonia nitrogen adsorption;

[0044] 3) Add the sludge containing three functional bacteria AnAOB, AOB, and NOB from the upper part of the sewage treatment container to the reactor filled with composite fillers, and promote the uniform mixing of microorganisms and composite fillers through aeration and sewage water flow to maintain The DO concentration is 0.5-1.5mg / L. At the same time, the solenoid coil is energized, and ...

Embodiment 3

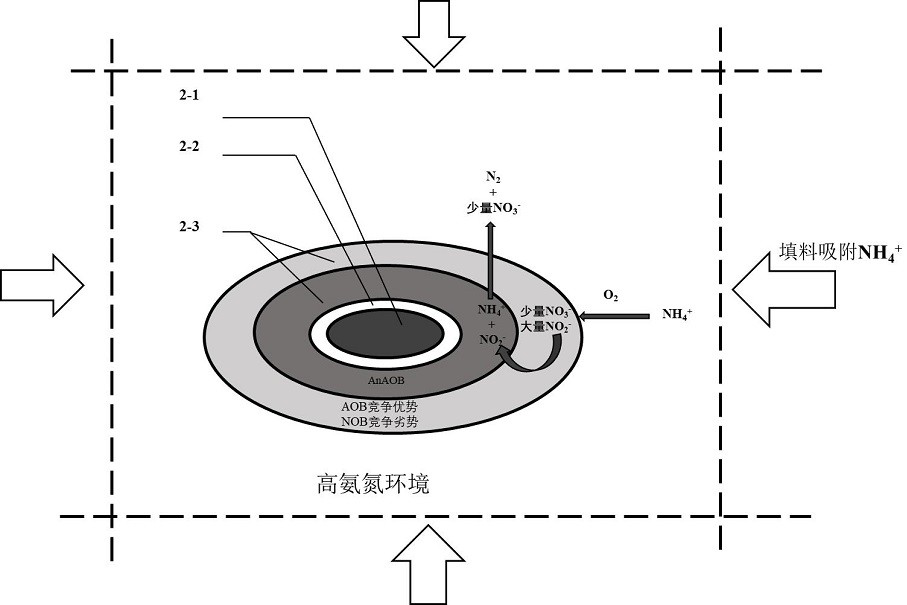

[0048] This embodiment relates to the distribution of AOB, AnAOB, and NOB inside and on the surface of the composite filler and its specific treatment process for ammonia nitrogen in sewage.

[0049] like figure 2 As shown, the alternating magnetic field generated by the external solenoid coil interacts with the metal inside the composite filler to generate eddy currents to generate heat, creating a local high-temperature microenvironment for the composite filler. On the one hand, it provides a suitable temperature for AOB and AnAOB, and improves microbial On the other hand, it is beneficial for AOB to win the competition with NOB (the outermost ring part in the figure), which expands the proportion of AOB, improves the accumulation rate of nitrous nitrogen, and reduces the impact of NOB and AnAOB on nitrous acid Salt competition promotes the growth of AnAOB (as shown in the light circle in the middle). The local high-temperature microenvironment maintains a significant diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com