Crystallization process of butamidoate citrate

A technology of butamid citrate and crystallization, which is applied in the field of crystallization technology of butamid citrate, can solve the problems of long centrifugation and drying time, difficulty in removing impurities and high cost, and achieves shortening of centrifugation and drying time. Time, reduce dry loss, improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

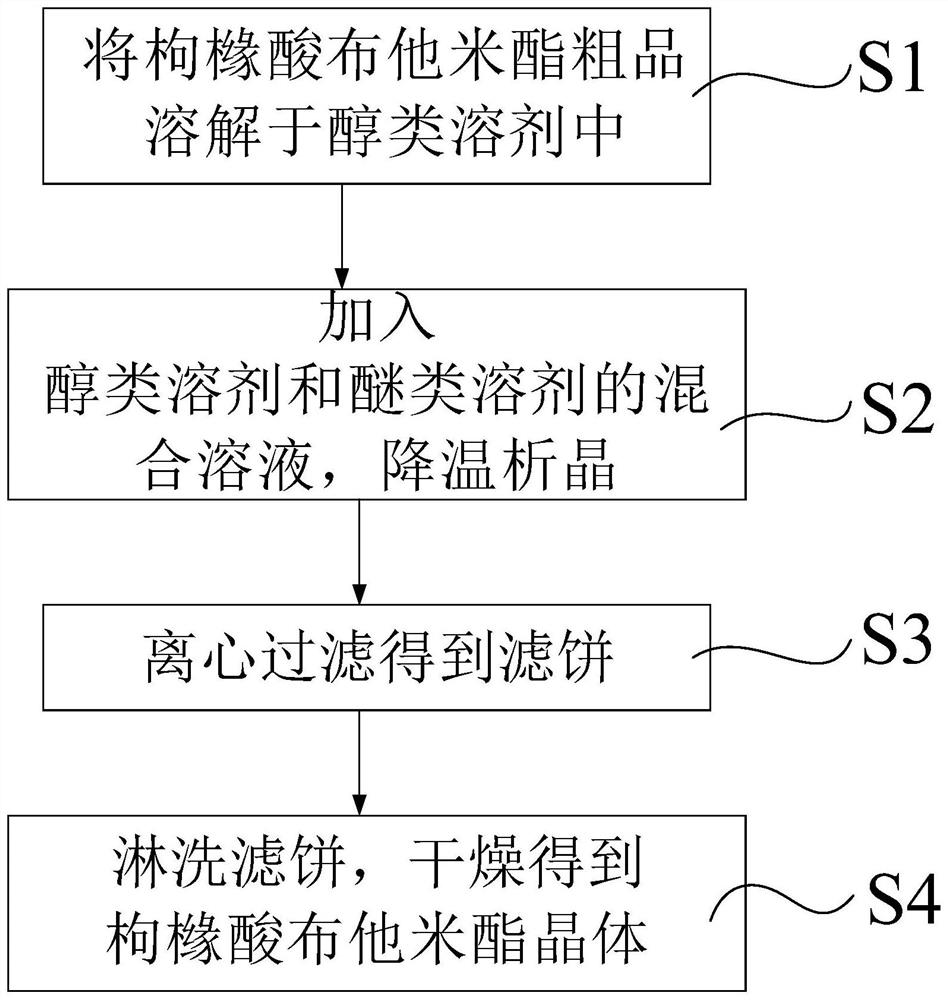

[0033] see figure 1 , a crystallization process of butamidate citrate, comprising the following process steps:

[0034] S1, mixing and dissolving: first, in the crystallization kettle, according to the quality of the alcohol solvent, the crude product of butamide citrate and the alcohol solvent are added successively according to the quality of the butamide citrate crude product 3-6 times, and the crystallization kettle The material is heated to 30-70°C, and at the same time, it is stirred until the butamidide citrate crude product is completely dissolved to obtain the first mixed solution; the alcohol solvent in step S1 is at least one of methanol, ethanol and isopropanol , preferably, the alcoholic solvent adopts isopropanol or ethanol; Preferably, the quality of the alcoholic solvent is 4-5 times of the crude product quality of butamide citrate; Preferably, the material in the crystallization tank is heated to 40 ~60°C.

[0035] S2. Crystallization: add a mixed solution o...

Embodiment 2

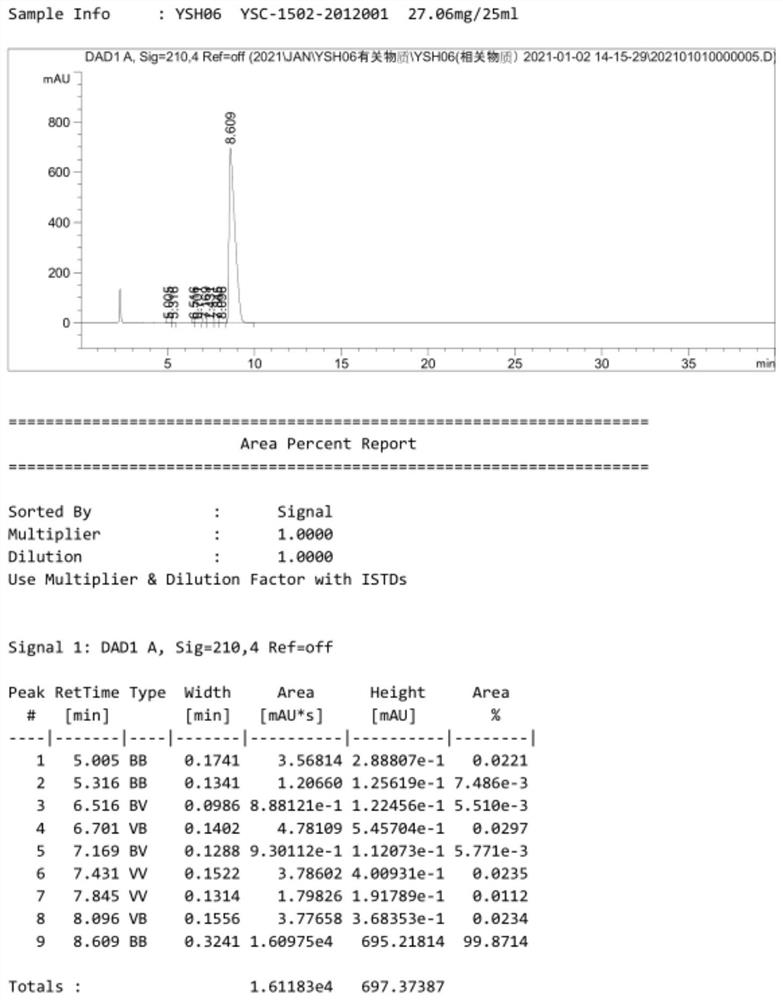

[0039] see figure 2 , put 30kg of crude butamidate citrate and 90kg of isopropanol into the crystallization kettle in turn, raise the temperature of the materials in the crystallization kettle to 30°C, stir until the materials are completely dissolved, then quickly drop into -15°C methanol and isopropanol The mixed solution of propyl ether is 180kg, the mass ratio of isopropanol and isopropyl ether is 1:9, the cooling rate is controlled at 10°C / h, and the stirring rate is 30r / min, so that the material in the crystallization tank is cooled to 0°C, and kept stirring for 1h , the material in the crystallization tank is subjected to solid-liquid separation through a centrifuge to obtain a filter cake and mother liquor, and the filter cake is washed with 15kg of isopropyl ether, and the washed solid is put into a dryer to dry, and the output is 29.79kg The yield of the butamide citrate crystals is 99.31%, the purity of the butamide citrate crystals reaches 99.87%, and the maximum ...

Embodiment 3

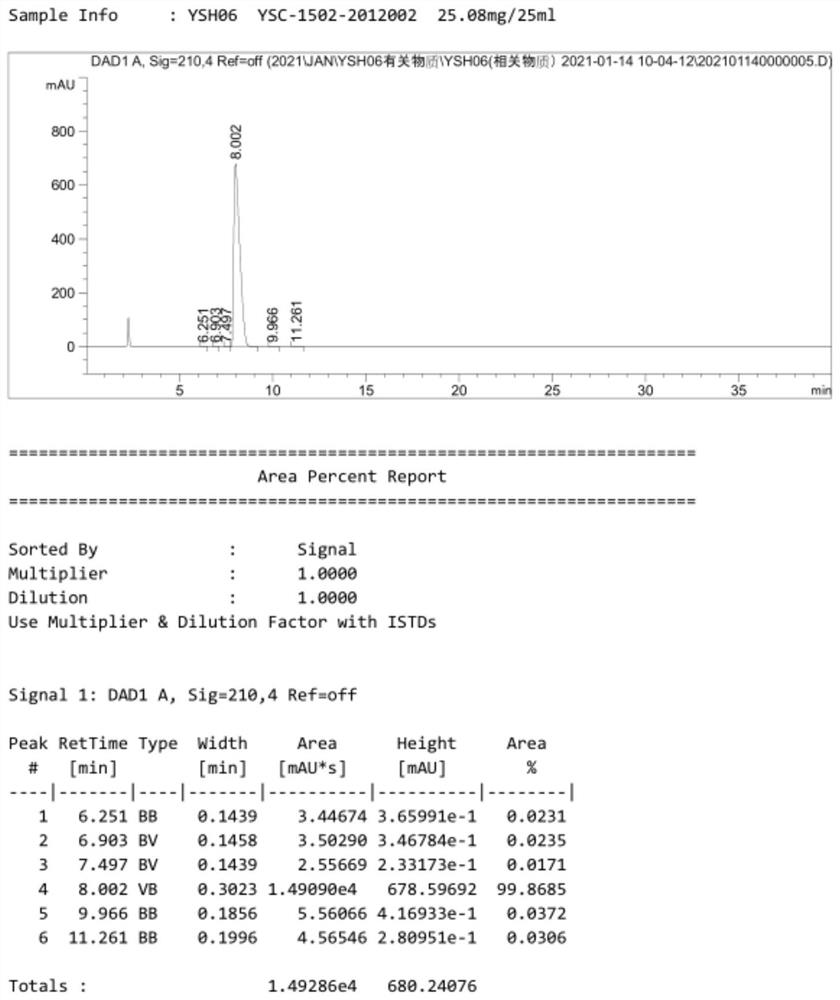

[0041] see image 3, put 30kg of crude butamidate citrate and 180kg of methanol into the crystallization tank in sequence, raise the temperature of the material in the crystallization tank to 70°C, stir until the material is completely dissolved, and quickly drop into 15°C of ethanol and methyl tert-butyl The mixed solution of ether is 300kg, the mass ratio of isopropanol and isopropyl ether is 8:2, the cooling rate is controlled at 15°C / h, and the stirring rate is 60r / min, so that the material in the crystallization tank is cooled to 5-7°C, and kept stirring 1h, the material in the crystallization tank was subjected to solid-liquid separation through a centrifuge to obtain a filter cake and mother liquor, and the filter cake was rinsed with 20kg of methyl tert-butyl ether, and the rinsed solid was put into a dryer for drying to produce Out of 29.81kg of butamidide citrate crystals, the yield is 99.37%, the purity of the butamidide citrate crystals reaches 99.87%, and the maxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com