Process for purifying soybean milk and extracting soybean isoflavone aglycone

A technology for isoflavone aglycone and yellow syrup water, which is applied in the field of purifying and extracting soybean isoflavone aglycone from yellow syrup water, and can solve the problems of low yield of aglycon-type isoflavones and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment includes the following steps:

[0027] 1. Pretreatment of yellow pulp water: put 250mL yellow pulp water into the bottle, lightly twist the cap, sterilize in boiling water bath at high temperature for 5 minutes, sterilize the bottle body with alcohol cotton ball, put it into the ultra-clean bench, and cool to room temperature;

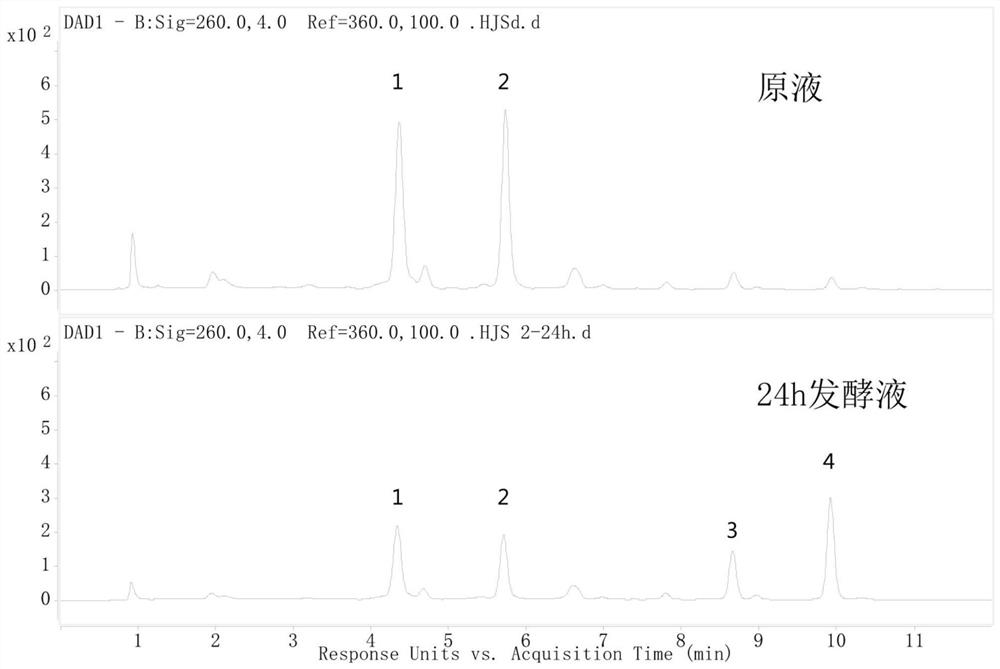

[0028] 2. Fermentation: Based on the inoculation amount of 3%, weigh 0.0075g of Lactobacillus acidophilus and add it to the bottle, then sterilize the bottle cap and bottle mouth with an alcohol lamp, shake well, and put it in a 37°C incubator to ferment for 24 hours; The yellow pulp water stock solution and the liquid after 24 hours of fermentation were filtered through a 0.22 μm filter membrane, pretreated by a solid-phase extraction cartridge, and the collected liquid was tested by high-performance liquid phase to obtain figure 1 , it can be seen that the content of aglycone increases significantly after fermentation;

[0029...

Embodiment 2

[0035] When preparing fermented yellow pulp water, Lactobacillus paracasei was selected as the fermentation strain, and the rest of the preparation steps refer to Example 1.

Embodiment 3

[0037] During the purification step, D-101 resin was used for adsorption, and the rest of the preparation steps refer to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com