Ultraviolet-resistant zinc-modified composite para-aramid fiber as well as preparation method and application thereof

A technology of para-aramid fiber and UV zinc, which is applied in the direction of light-resistant fiber, fiber type, fiber treatment, etc., can solve the problems of poor radiation resistance and achieve the goals of reducing comprehensive performance, improving surface activity, and improving UV resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

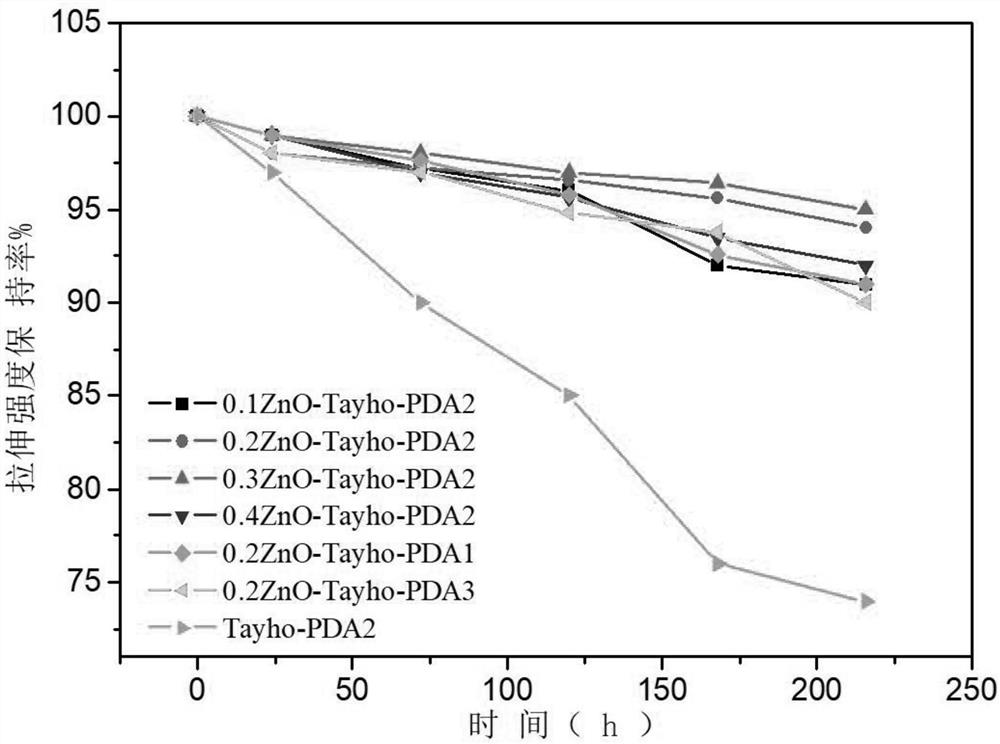

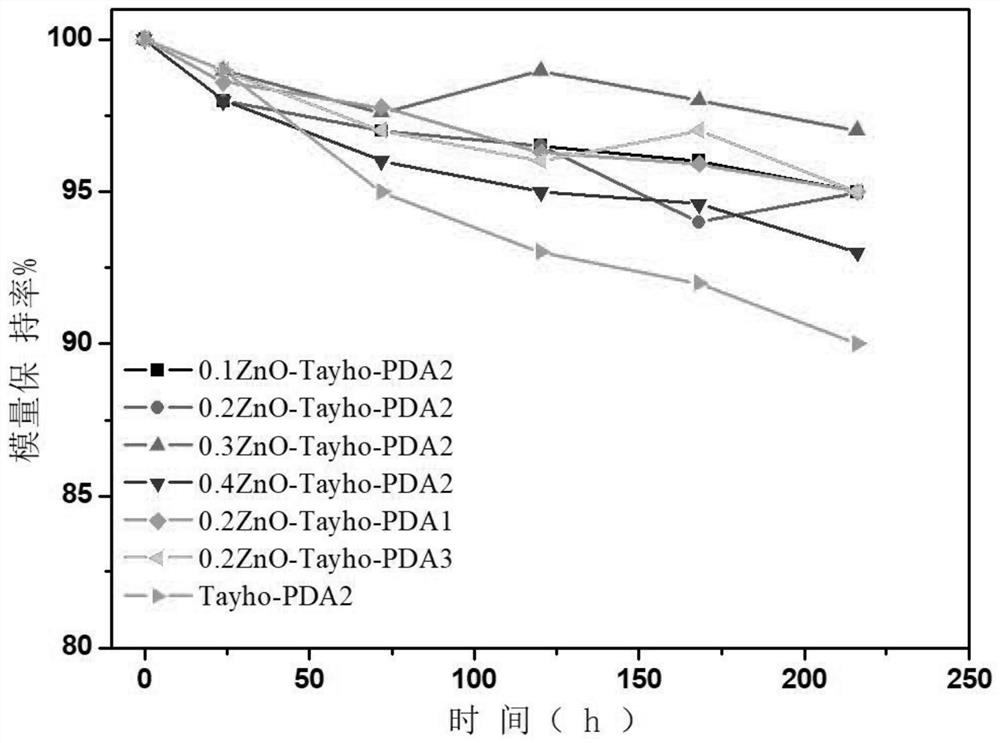

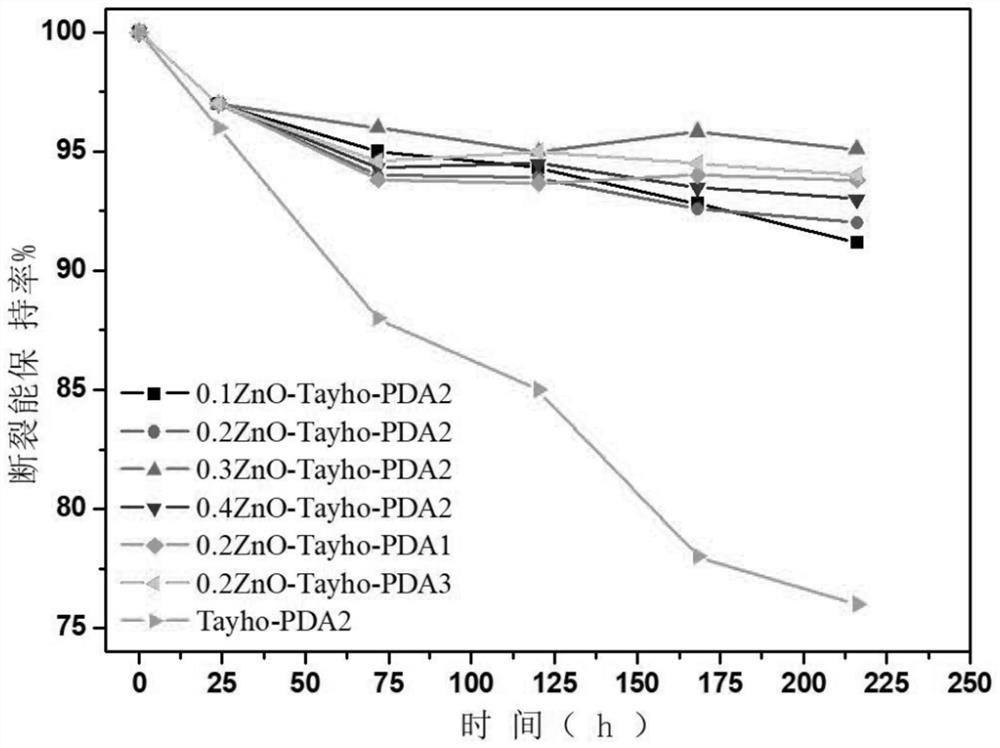

[0025] Embodiment 1, a method for preparing a UV-resistant zinc modified composite para-aramid fiber of the present invention, comprising the following steps:

[0026] (1) Dissolve the zinc salt in ethanol at 60-80°C to obtain solution A with a solution concentration of 0.1mol / L, then add 32mg of alkali solution to 140mL of ethanol, and then add 1g of polyethylene glycol to obtain solution B, Then A and B solutions were mixed under vigorous stirring, and after 30 minutes, the mixed solution was cooled in ice water to obtain a clear and transparent ZnO seed solution with a concentration of 0.1mol / L;

[0027] (2) The exposed Tayho was washed sequentially in acetone, petroleum ether and deionized water, Soxhlet extraction was performed at 50°C for 24 hours, and then dried in a vacuum oven at 80°C for 6 hours; another 1mL tris solution (1M ) in a 100mL volumetric flask, set to volume, prepare 10mM Tris solution, then prepare 2g / L DA solution, adjust the pH of DA solution to 8.5 wi...

Embodiment 2

[0029] Embodiment 2, a method for preparing a UV-resistant zinc modified composite para-aramid fiber of the present invention, comprising the following steps:

[0030] (1) Dissolve the zinc salt in ethanol at 60-80°C to obtain solution A with a solution concentration of 0.2mol / L, then add 32mg of alkali solution to 140mL of ethanol, and then add 1g of polyethylene glycol to obtain solution B, Then A and B solutions were mixed under vigorous stirring, and after 30 minutes, the mixed solution was cooled in ice water to obtain a clear and transparent ZnO seed solution with a concentration of 0.2 mol / L;

[0031] (2) The exposed Tayho was washed sequentially in acetone, petroleum ether and deionized water, Soxhlet extraction was performed at 50°C for 24 hours, and then dried in a vacuum oven at 80°C for 6 hours; another 1mL tris solution (1M ) in a 100mL volumetric flask, set to volume, prepare 10mM Tris solution, then prepare 2g / L DA solution, adjust the pH of the solution to 8.5 ...

Embodiment 3

[0033] Embodiment 3, a method for preparing a UV-resistant zinc modified composite para-aramid fiber of the present invention, comprising the following steps:

[0034] (1) Dissolve zinc salt in ethanol at 60-80°C to obtain solution A with a solution concentration of 0.3mol / L, then add 32mg of alkali solution to 140mL of ethanol, and then add 1g of polyethylene glycol to obtain solution B, Then A and B solutions were mixed under vigorous stirring, and after 30 minutes, the mixed solution was cooled in ice water to obtain a clear and transparent ZnO seed solution with a concentration of 0.3mol / L;

[0035] (2) The exposed Tayho was washed sequentially in acetone, petroleum ether and deionized water, Soxhlet extraction was performed at 50°C for 24 hours, and then dried in a vacuum oven at 80°C for 6 hours; another 1mL tris solution (1M ) in a 100mL volumetric flask, constant volume, prepare 10mM polytrishydroxymethylaminomethane solution, then prepare 2g / L DA solution respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com