CO2 transcritical parallel compression refrigeration system and control method

A compression refrigeration and control method technology, which is applied in the direction of refrigerators, compressors, compressors, etc., can solve the problem that the system deviates from the optimal performance point, and achieve the effect of improving system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

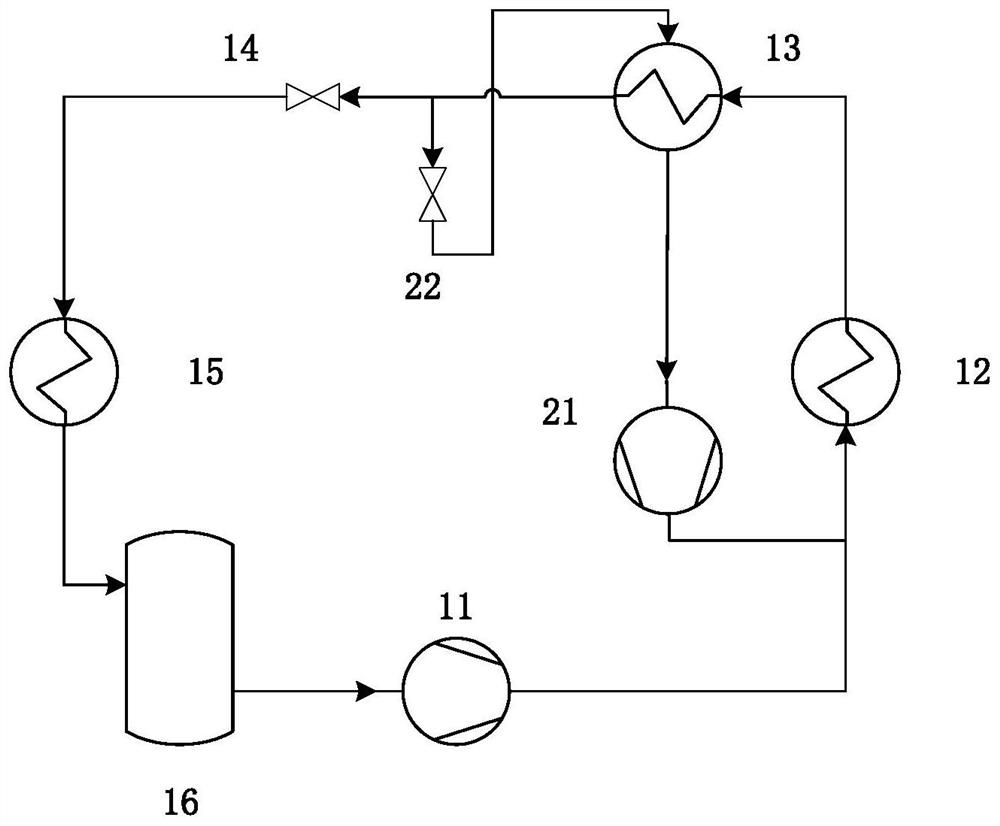

[0070] see figure 1 As shown, the present invention provides a CO 2 Transcritical parallel compression refrigeration system, including: main channel transcritical CO 2 Cyclic and branch near-critical CO 2 cycle device.

[0071] main road transcritical CO 2 The circulation device includes a main compressor 11 , a gas cooler 12 , a regenerator 13 , a main road throttling valve 14 , an evaporator 15 and a gas-liquid separator 16 which are sequentially connected in circulation.

[0072] branch near critical CO 2 The cycle includes a bypass throttle valve 22 and an auxiliary compressor 21; CO 2 After passing through the regenerator 13, bypass all the way into the branch circuit, throttle through the branch throttle valve 22, then enter the regenerator 13 for heat exchange, enter the auxiliary compressor 21 for compression, and then merge into the gas cooling in the main circuit Heat dissipation in device 12.

Embodiment 2

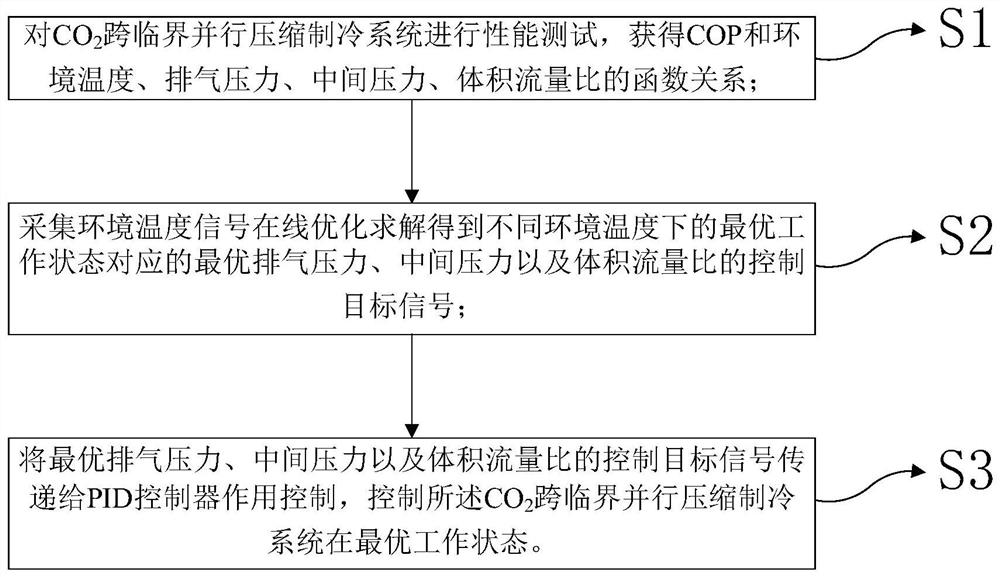

[0074] see figure 2 As shown, the present invention also provides a CO described in Example 1 2 Control methods for transcritical parallel compression refrigeration systems. The present invention a kind of CO 2 The optimal working state of the transcritical parallel compression refrigeration system is the inlet pressure of the gas cooler 12, which is the discharge pressure, the suction pressure of the auxiliary compressor 21, which is the intermediate pressure, and the volume of the auxiliary compressor 21 when the refrigeration COP is the highest when the system is running stably. The ratio of the flow rate and the volumetric flow rate of the main compressor 11 is the volumetric flow ratio; the optimal working state is obtained through the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com