MPO interface-based single fan-in and fan-out multi-channel optical module

An optical module and multi-channel technology, which is applied in the field of optical modules, can solve problems such as interface density bottlenecks, and achieve the effects of cost optimization, reduced preparation difficulty, and saving the amount of external wiring fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

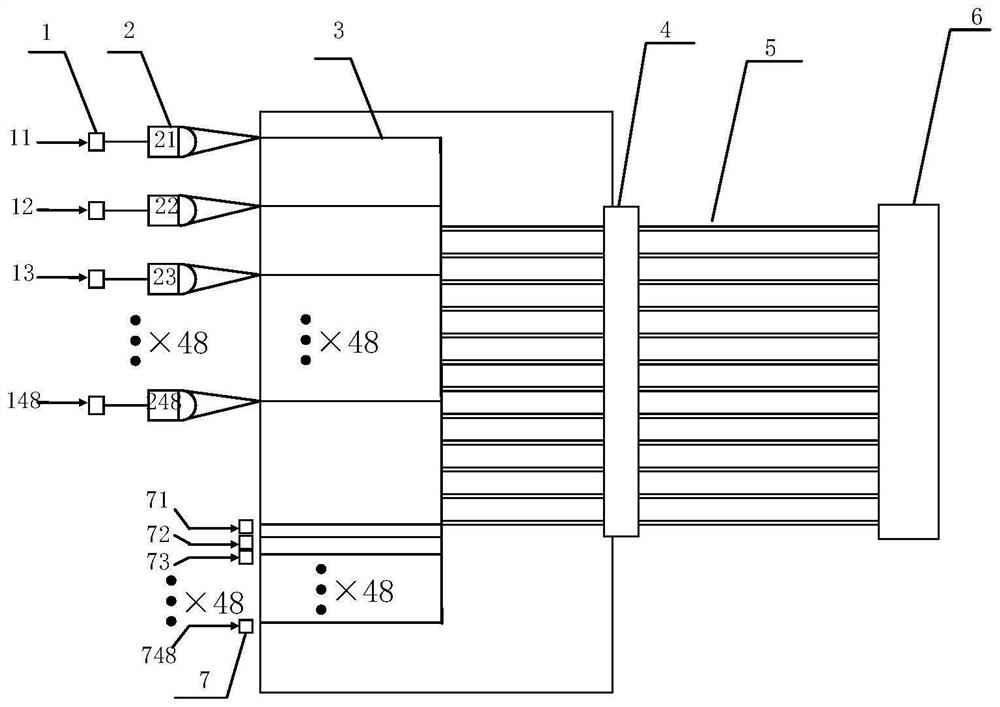

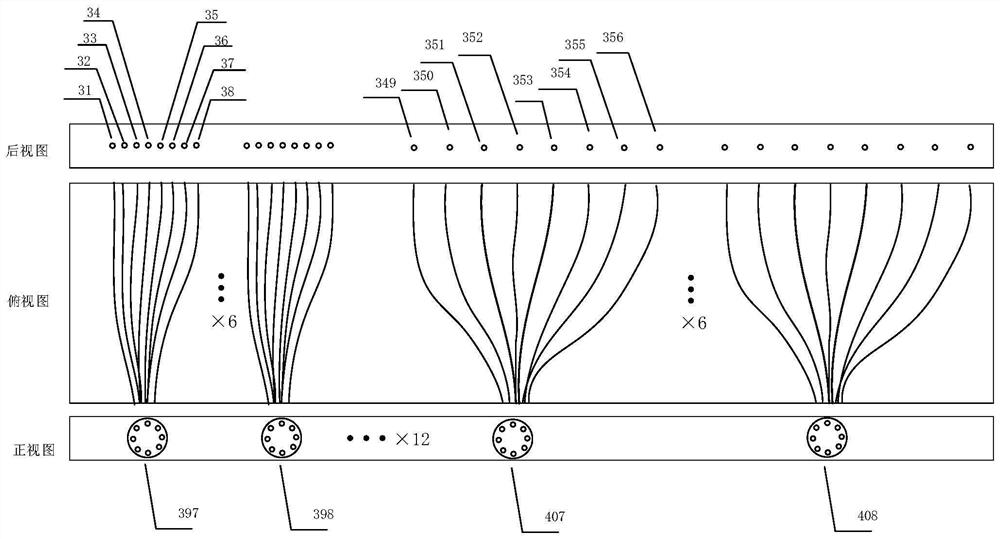

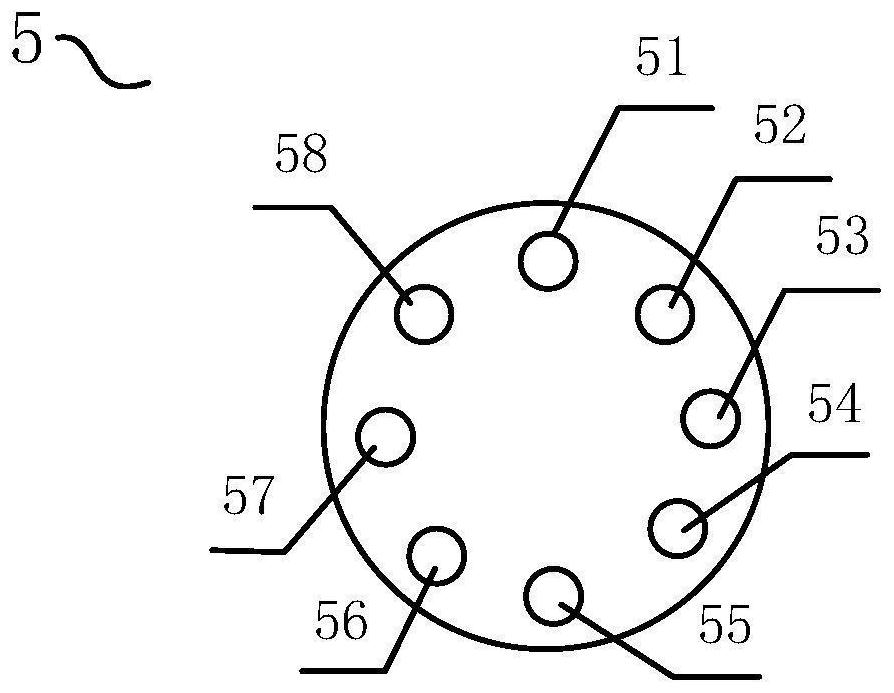

[0025] Such as figure 1 , figure 2 , image 3 As shown, a new multi-channel optical module includes 48-channel LD module 1 (11-148) arranged in sequence along the optical axis, 96-channel 8-core fiber fan-in and fan-out device 3, eight-core fiber array 4, And the 8-core optical fiber 5 (each core number: 51~58) coupled with the fan-in and fan-out output end of the 8-core optical fiber, and the 8-core optical fiber MPO connector 6 connected with 12 8-core optical fibers. 48-channel LD mode Between the group 1 and the input end of the 96-channel 8-core optical fiber fan-in and fan-out device 3, there are 48 first focusing lenses 2 (numbers 21-248) corresponding to the 48 channels of the LD module, which are used to direct the laser The 48 divergent light sources emitted by the module are converged and coupled to the 48 input ports 349-396 of the fan-in-fan-out device, and enter the six 8-core optical fibers 397-408 from the output end of the fan-in-fan-out device.

[0026] T...

Embodiment 2

[0029] The number of lasers in the laser array in embodiment 2, the number of detectors in the detector array, the number of cores of the multi-core optical fiber and the channel number of fan-in and fan-out devices are all the same as the relevant numbers in embodiment 1, and the number of lasers and detectors The arrangement is a 3*16 rectangular arrangement.

Embodiment 3

[0031] The number of lasers in the laser array, the number of detectors in the detector array, the number of cores of the multi-core optical fiber and the number of channels of the fan-in and fan-out devices in the third embodiment are all twice the relevant numbers in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com