A kind of high nickel ternary composite positive electrode and lithium ion battery containing solid electrolyte

A solid electrolyte, ternary composite technology, applied in the direction of batteries, positive electrodes, electrical components, etc., can solve the problems of high temperature cycle performance, high temperature storage performance, safety, structural stability and thermal stability. Improve the effect of reducing ionic conductivity, high energy density, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

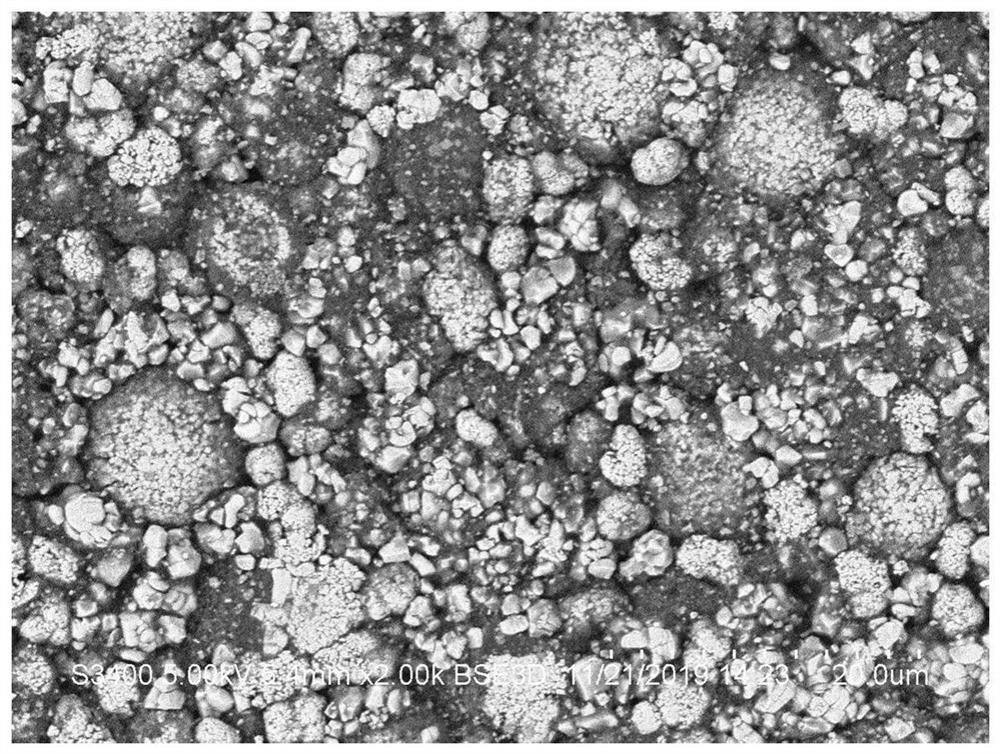

Image

Examples

Embodiment 1

[0051] Stir 1.5 parts of PVDF until transparent glue, add 1.3 parts of carbon nanotube / conductive carbon black mixture, stir well, then add 97.2 parts of NCM811, continue stirring, then add 0.1 parts of inorganic solid electrolyte Li 2 O-Al 2 o 3 -SiO 2 -P 2 o 5 -TiO 2 -GeO, stirred and dispersed evenly, then coated on the surface of the aluminum current collector, dried for use;

[0052] Stir 1.3 parts of CMC until transparent, add 1 part of conductive graphite, stir evenly, then add 96 parts of artificial graphite, continue stirring, then add 1.7 parts of styrene-butadiene rubber emulsion, stir and disperse evenly, and evenly coat the surface of the negative electrode collector. drying for use;

[0053] The coated positive and negative electrodes are cut and punched, and then the positive and negative electrodes are separated by a diaphragm, packaged with aluminum-plastic film, injected with self-made electrolyte, fully infiltrated, and dissolved to obtain lithium ion...

Embodiment 2

[0055] Stir 1.5 parts of PVDF until transparent glue, add 1.3 parts of carbon nanotube / conductive carbon black mixture, stir well, then add 96.7 parts of NCM811, continue stirring, then add 0.5 parts of inorganic solid electrolyte Li 2 O-Al 2 o 3 -SiO 2 -P 2 o 5 -TiO 2 -GeO, stirred and dispersed evenly, then coated on the surface of the aluminum current collector, dried for use;

[0056] Stir 1.3 parts of CMC until transparent, add 1 part of conductive graphite, stir evenly, then add 96 parts of artificial graphite, continue stirring, then add 1.7 parts of styrene-butadiene rubber emulsion, stir and disperse evenly, and evenly coat the surface of the negative electrode collector. drying for use;

[0057] The coated positive and negative electrodes are cut and punched, and then the positive and negative electrodes are separated by a diaphragm, packaged with aluminum-plastic film, injected with self-made electrolyte, fully infiltrated, and dissolved to obtain lithium ion...

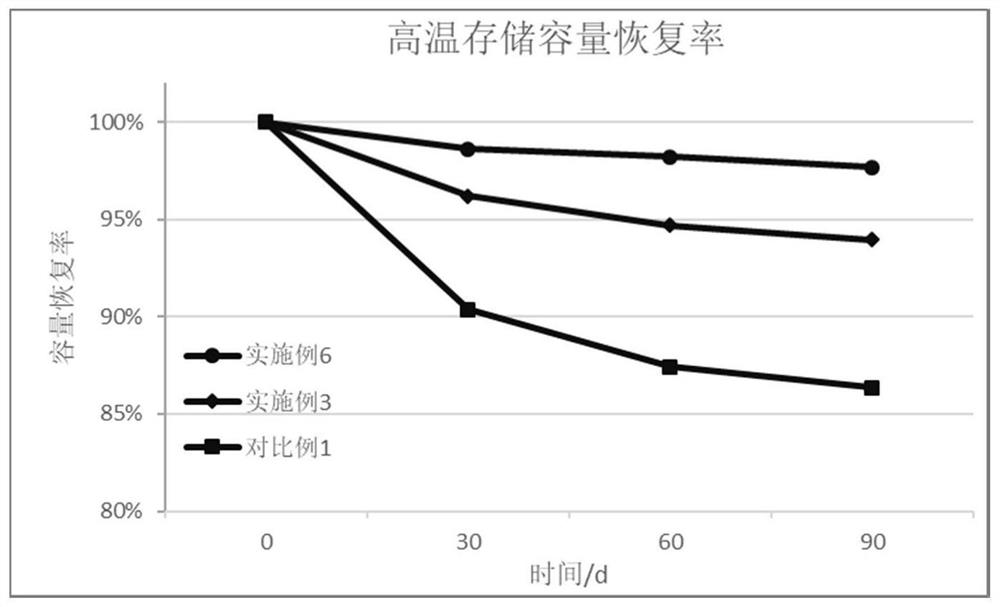

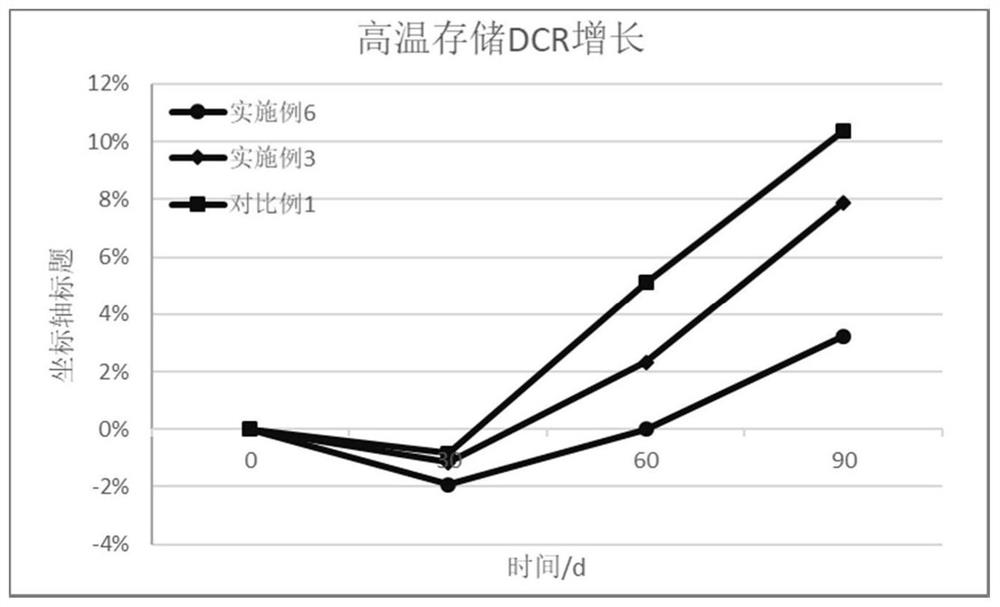

Embodiment 3

[0059] Stir 1.5 parts of PVDF until transparent glue, add 1.3 parts of carbon nanotube / conductive carbon black mixture, stir well, then add 96.2 parts of NCM811, continue stirring, then add 1 part of inorganic solid electrolyte Li 2 O-Al 2 o 3 -SiO 2 -P 2 o 5 -TiO 2 -GeO, stirred and dispersed evenly, then coated on the surface of the aluminum current collector, dried for use;

[0060] Stir 1.3 parts of CMC until transparent, add 1 part of conductive graphite, stir evenly, then add 96 parts of artificial graphite, continue stirring, then add 1.7 parts of styrene-butadiene rubber emulsion, stir and disperse evenly, and evenly coat the surface of the negative electrode collector. drying for use;

[0061] The coated positive and negative electrodes are cut and punched, and then the positive and negative electrodes are separated by a diaphragm, packaged with aluminum-plastic film, injected with self-made electrolyte, fully infiltrated, and dissolved to obtain lithium ion ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com