Monocrystal ternary positive electrode material, preparation method and battery

A cathode material, single crystal technology, applied in the field of preparation of single crystal ternary cathode materials, can solve the problems of reduced material stability, increased material cost, and reduced compaction density of pole pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

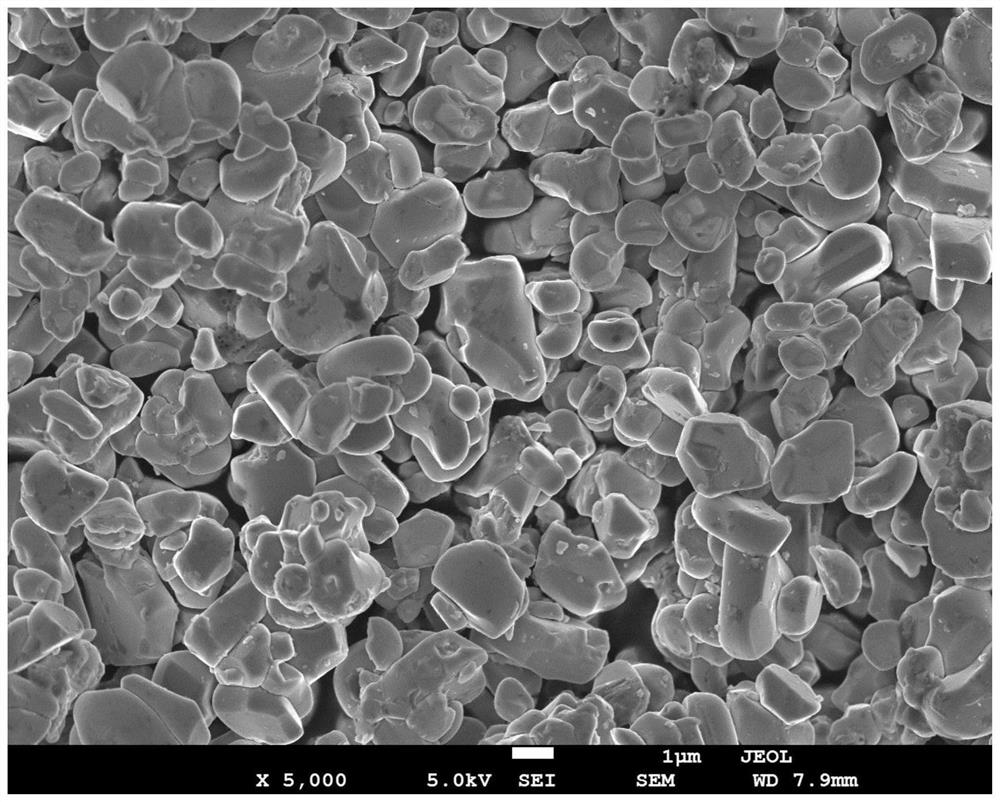

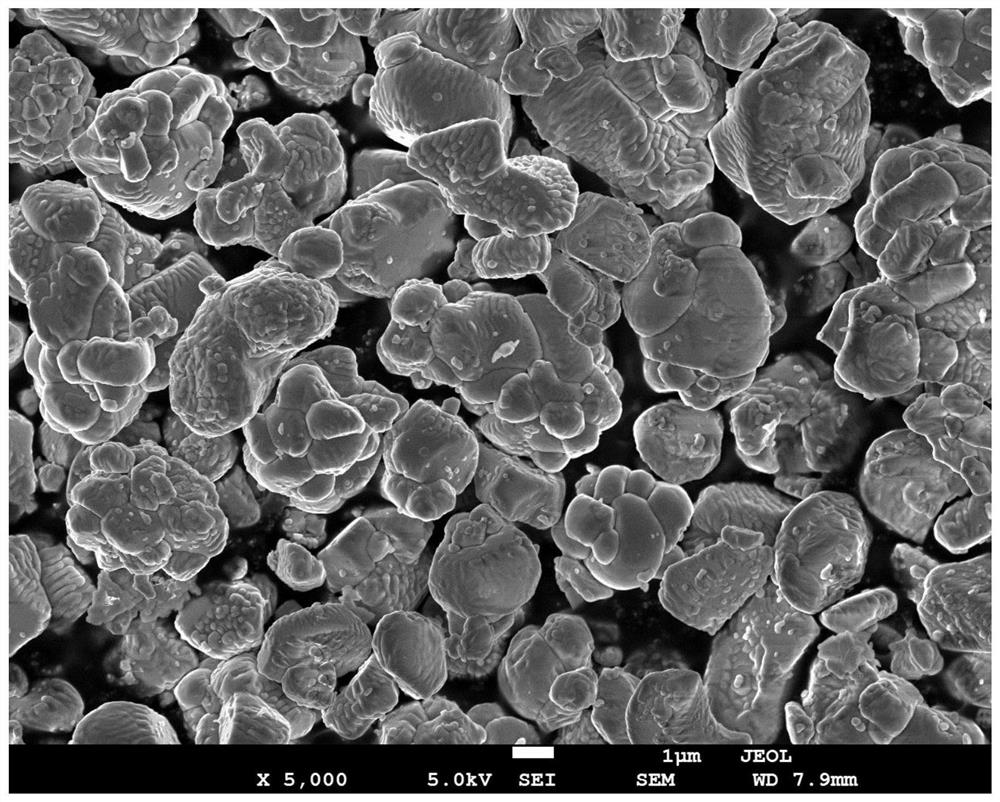

Image

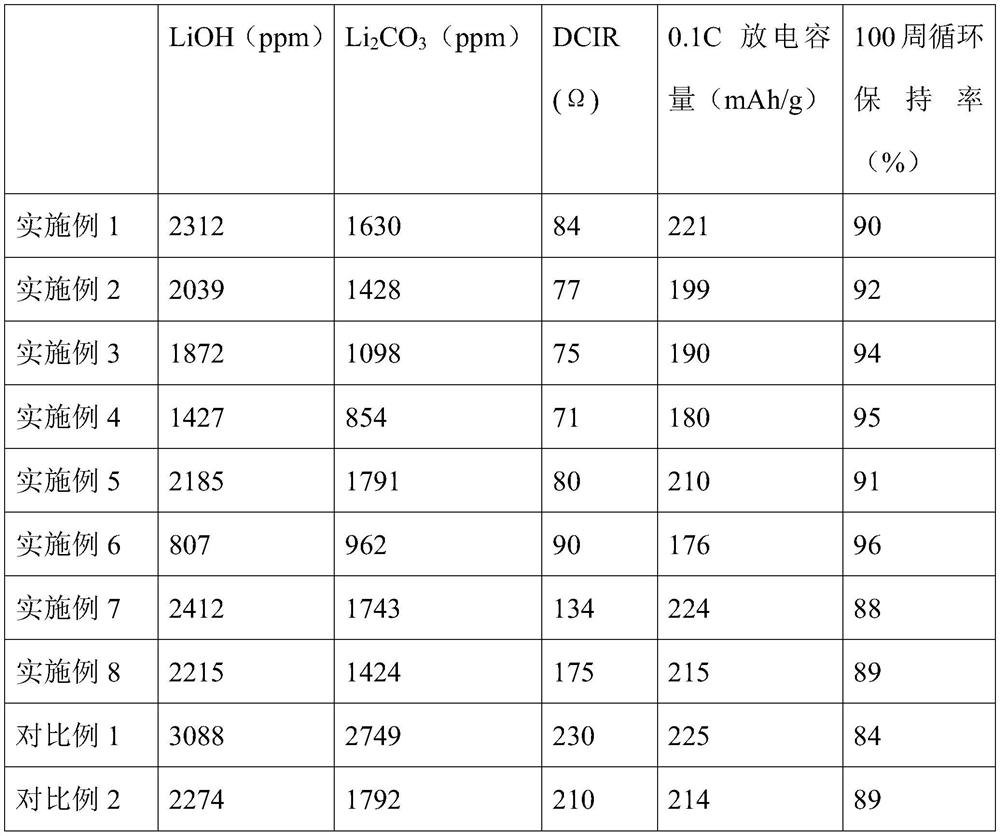

Examples

Embodiment 1

[0053] This embodiment provides a method for preparing a single crystal ternary cathode material, and the preparation method specifically includes the following steps:

[0054] (1) nickel chloride, cobalt chloride and manganese chloride are mixed with the mixed salt solution that concentration is 1mol / L by stoichiometric ratio, meanwhile, prepare the sodium hydroxide solution of 2mol / L and the ammonia solution of 5wt%; Mixed salt solution, sodium hydroxide solution and ammonia solution are added to the mixer at the same time according to the volume ratio of 1:2:0.2, the pH of the mixed solution is controlled at 8, the reaction temperature is 50°C, the stirring speed is 600r / min, and the stirring time is 10h, the precipitate obtained by the reaction was successively filtered, washed and dried to obtain the precursor Ni 0.9 co 0.05 mn 0.05 (OH) 2 ;

[0055] (2) Ni 0.9 co 0.05 mn 0.05 (OH) 2 Precursor and lithium hydroxide are mixed and ball milled, wherein the lithium ra...

Embodiment 2

[0058] This embodiment provides a method for preparing a single crystal ternary cathode material, and the preparation method specifically includes the following steps:

[0059] (1) Nickel nitrate, cobalt nitrate and manganese nitrate are mixed into the mixed salt solution that concentration is 1.5mol / L by stoichiometric ratio, meanwhile, the sodium hydroxide solution of preparation 3mol / L and the ammonia solution of 8wt%; Mixed salt Solution, sodium hydroxide solution and ammonia solution were added to the stirrer at the same time according to the volume ratio of 1.5:3:1, the pH of the mixed solution was controlled at 9, the reaction temperature was 55°C, the stirring speed was 500r / min, and the stirring time was 12h. The precipitate obtained from the reaction was successively filtered, washed and dried to obtain the precursor Ni 0.7 co 0.15 mn 0.15 (OH) 2 ;

[0060] (2) Ni 0.7 co 0.15 mn 0.15 (OH) 2 The precursor and lithium carbonate were mixed and ball milled, where...

Embodiment 3

[0063] This embodiment provides a method for preparing a single crystal ternary cathode material, and the preparation method specifically includes the following steps:

[0064] (1) Nickel sulfate, cobalt sulfate and manganese sulfate are mixed into the mixed salt solution that concentration is 4mol / L by stoichiometric ratio, meanwhile, the sodium hydroxide solution of preparation 4mol / L and the ammoniacal solution of 10wt%; Mixed salt solution , sodium hydroxide solution and ammonia solution are simultaneously added to the stirrer according to the volume ratio of 2:4:1, the pH of the mixed solution is controlled at 13, the reaction temperature is 70°C, the stirring speed is 300r / min, and the stirring time is 15h. The resulting precipitate was filtered, washed and dried to obtain the precursor Ni 0.65 co 0.1 mn 0.35 (OH) 2 ;

[0065] (2) Ni 0.65 co 0.1 mn 0.35 (OH) 2 Precursor and lithium chloride are mixed and ball milled, wherein the lithium ratio Li / (Ni+Co+Mn)=1.03, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com