Kettle type polymerization reactor

A polymerization reactor and reactor technology, applied in chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc., can solve the problem of product stability deterioration, initial decomposition temperature Lowering, unsatisfactory mixing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

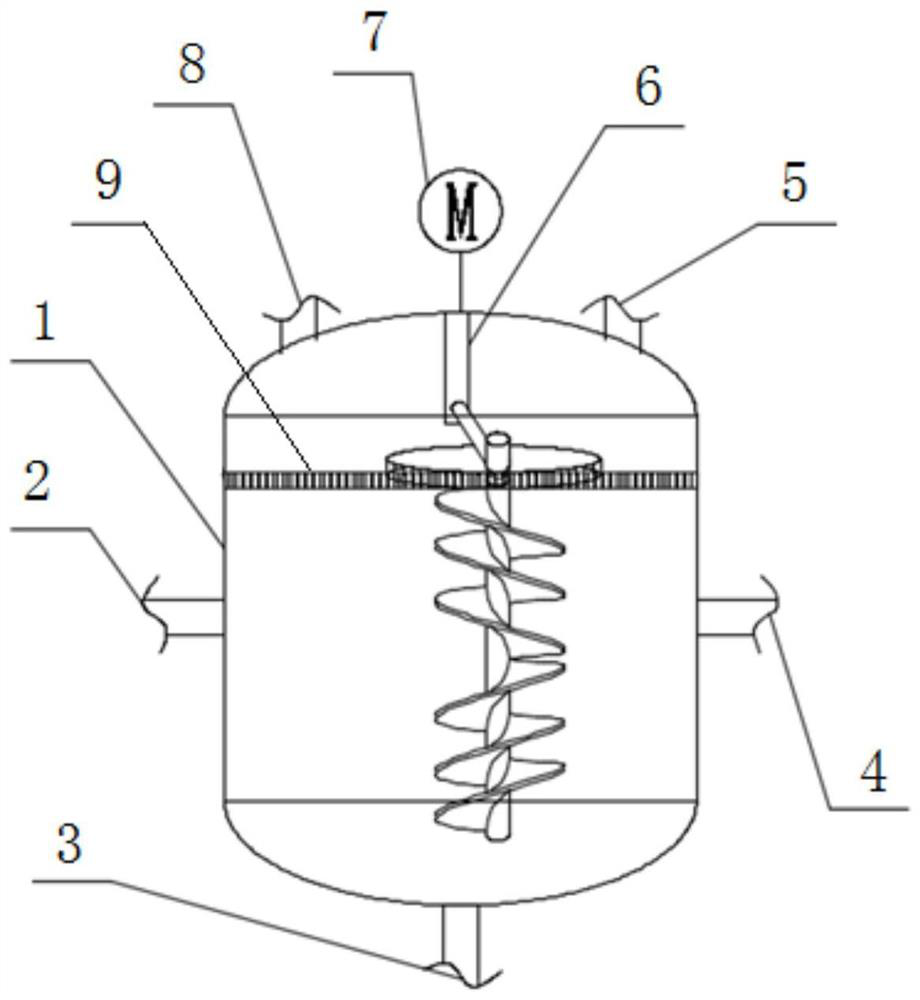

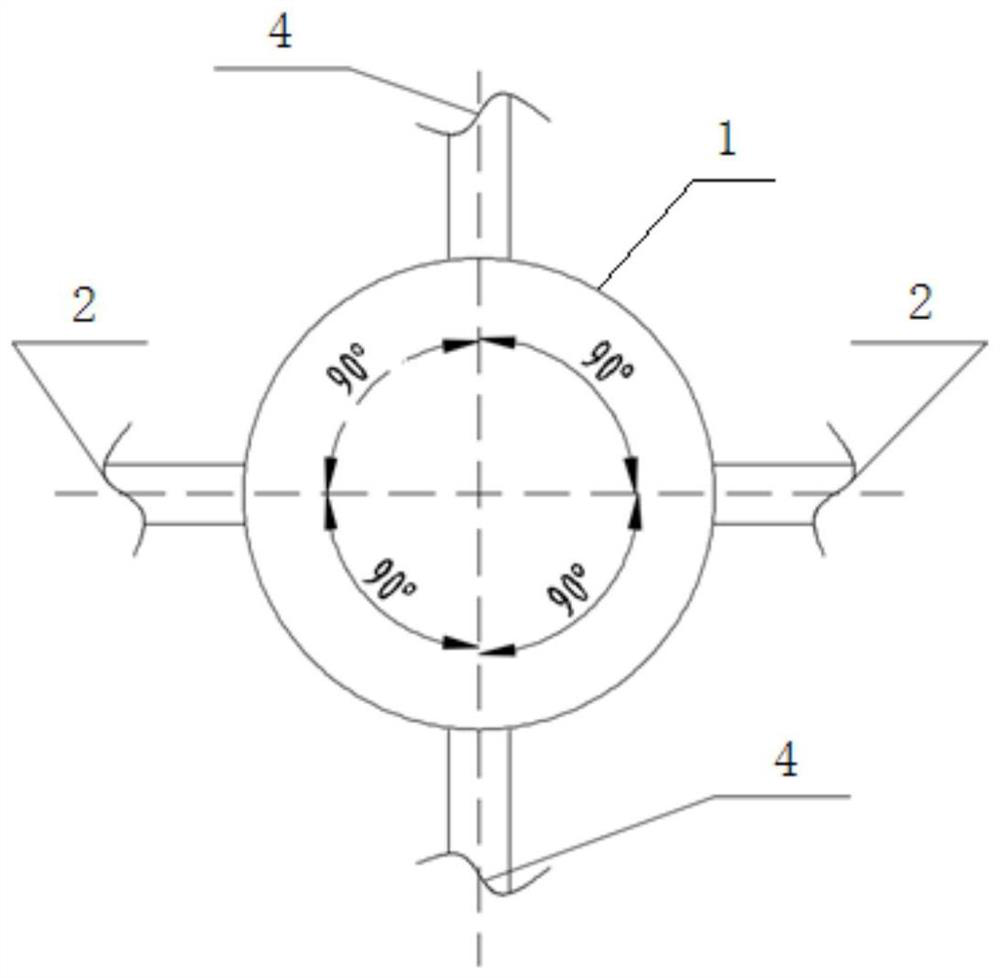

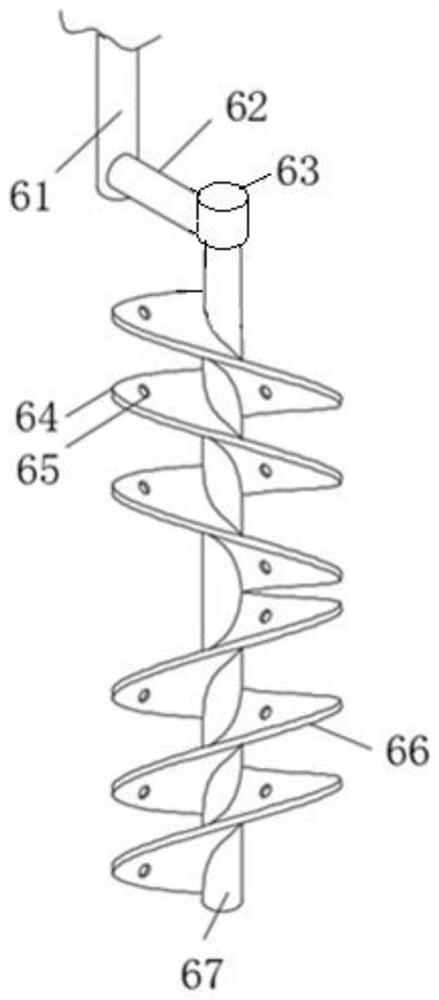

[0030] The invention provides a tank type polymerization reactor, such as figure 1 As shown, including the reactor main body 1, the top of the reactor main body 1 is provided with a gas phase outlet 5 and a solvent return port 8, two water phase feed ports 2 and two oil phase feed ports 4 are provided on the side wall, and a discharge port is provided at the bottom Mouth 3. The oil phase feed port 4 is located above the water phase feed port 2, and the oil phase feed port 4 and the water phase feed port 2 are uniformly and alternately distributed along the circumferential direction of the side wall of the reactor main body 1. Such as figure 2 As shown, in this embodiment, the angle between the inlet center of the adjacent water phase feed port 2 and the oil phase feed port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com