Method and system for cleaning stubborn dirt on surface of solar photovoltaic panel

A technology for solar photovoltaic panels and cleaning systems, which is applied in the directions of cleaning methods, cleaning methods and utensils using gas flow, photovoltaic power generation, etc., and can solve the problems of stubborn dirt on the surface of solar photovoltaic panels that are difficult to clean and the cost of manual cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

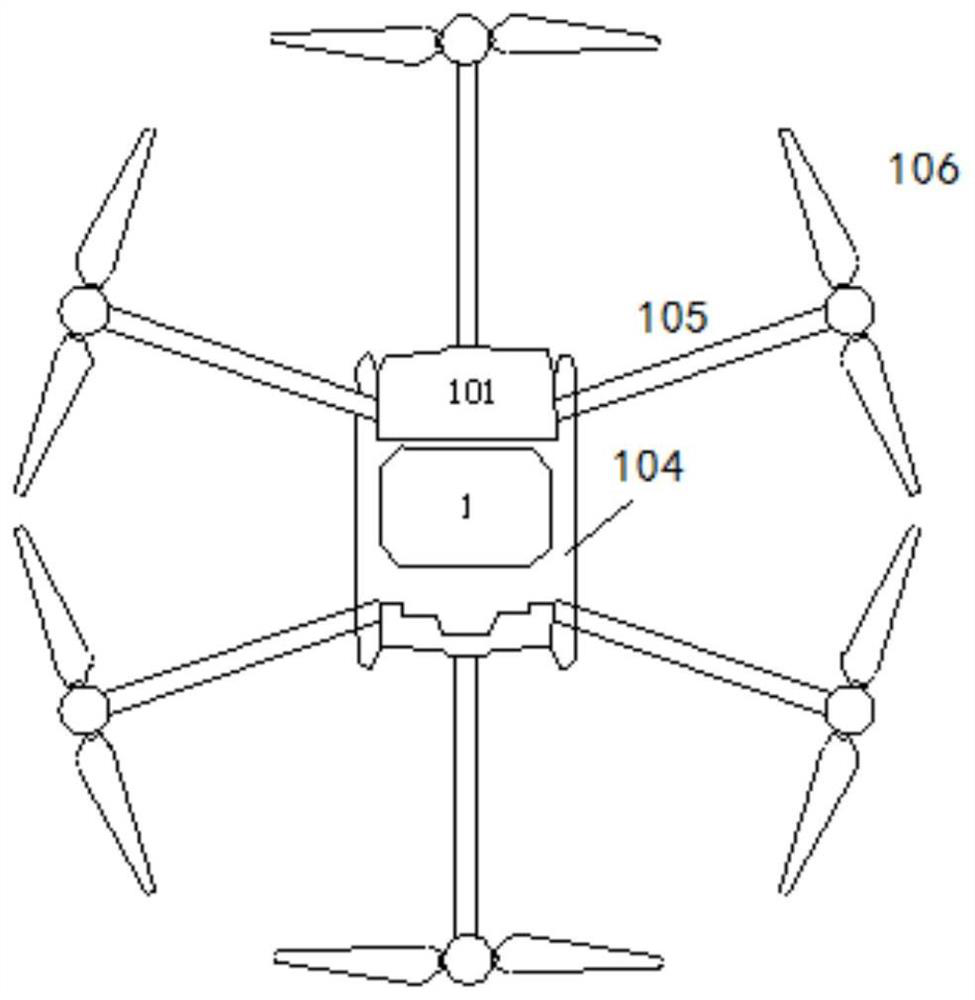

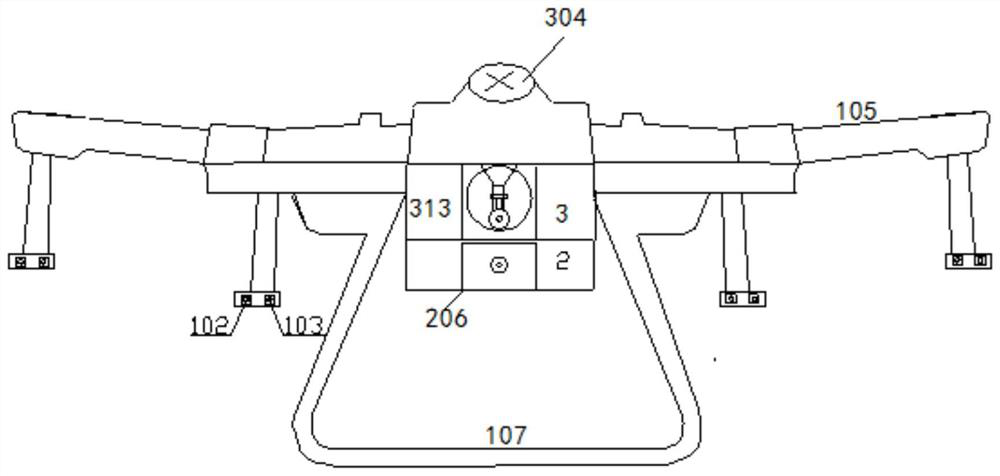

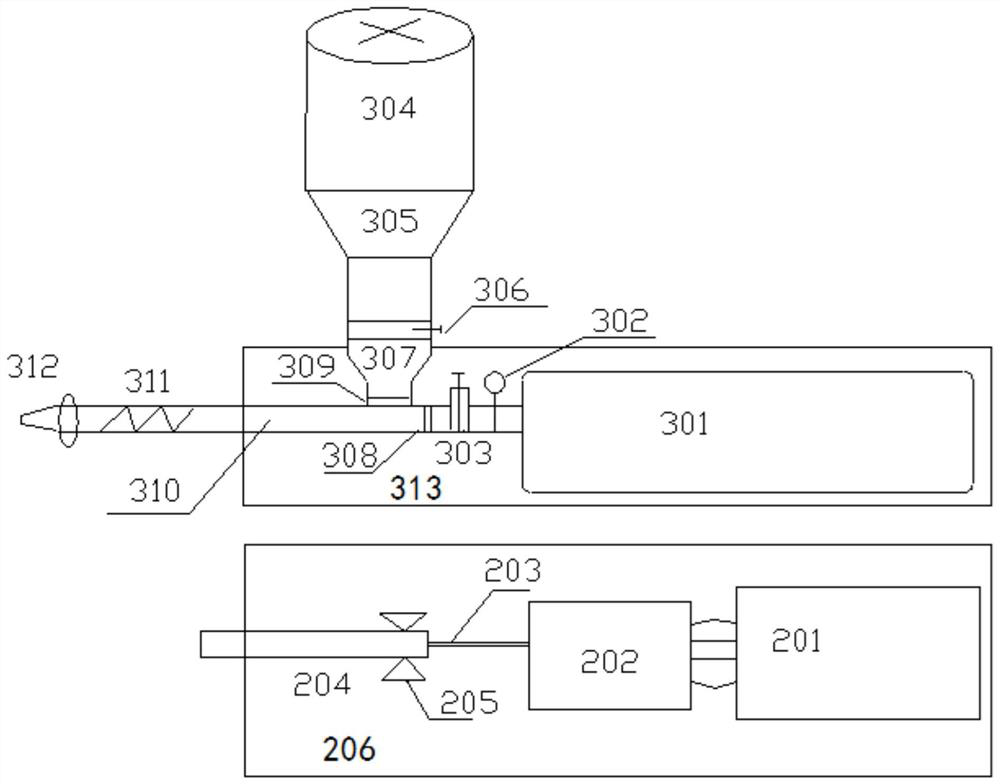

[0070] The drone inspects the photovoltaic panels, determines the specific location information of the photovoltaic panel dirt through the infrared camera 102 and the dirt positioning system 101, and then controls the drone to hover within 1 meter of the dirt location, and aims the laser at the stubborn dirt on the photovoltaic panel. Adjust the wavelength to 100nm, and after 5 seconds of working time, the telescopic pipeline 311 is stretched out, so that the rotating nozzle 312 is outside the downwind area of the drone, and then the solenoid valve 302 is started, and the carbon fiber compressed air bottle 301 outputs air, and the air passes through the pressure reducing valve After 303 is decompressed, the outlet pressure is 0.4MPa, so that the air is ejected from the rotating nozzle 312 to clean the impurity gas in the pipeline; adjust the adjustable channel 307 to make the dry ice flow rate 0.2kg / min; after 2s, touch the pneumatic valve 306 When it is turned on, the dry ic...

Embodiment 2

[0072] The drone inspects the photovoltaic panels, determines the specific location information of the photovoltaic panel dirt through the infrared camera 102 and the dirt positioning system 101, and then controls the drone to hover within 1 meter of the dirt location, and aims the laser at the stubborn dirt on the photovoltaic panel. Adjust the wavelength to 3000nm, and after working for 5s, the telescopic pipeline 311 is stretched out, so that the rotating nozzle 312 is outside the downwind area of the drone, and then the solenoid valve 302 is started, and the carbon fiber compressed air bottle 301 outputs air, and the air passes through the pressure reducing valve After 303 is decompressed, the outlet pressure is 0.6MPa, so that the air is ejected from the rotary nozzle 312, and the impurity gas in the pipeline is cleaned; the adjustable channel 307 is adjusted to make the dry ice flow rate 0.3kg / min; after 2s, the pneumatic valve 306 is activated When it is turned on, the...

Embodiment 3

[0074]The drone inspects the photovoltaic panels, determines the specific location information of the photovoltaic panel dirt through the infrared camera 102 and the dirt positioning system 101, and then controls the drone to hover within 1 meter of the dirt location, and aims the laser at the stubborn dirt on the photovoltaic panel. Adjust the wavelength to 1500nm, and after working for 5s, the telescopic pipeline 311 is stretched out, so that the rotating nozzle 312 is outside the downwind area of the drone, and then the solenoid valve 302 is activated, the carbon fiber compressed air bottle 301 outputs air, and the air passes through the pressure reducing valve After 303 is decompressed, the outlet pressure is 0.5MPa, so that the air is ejected from the rotary nozzle 312, and the impurity gas in the pipeline is cleaned; the adjustable channel 307 is adjusted to make the dry ice flow rate 0.25kg / min; after 2s, the pneumatic valve 306 is activated When it is turned on, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com