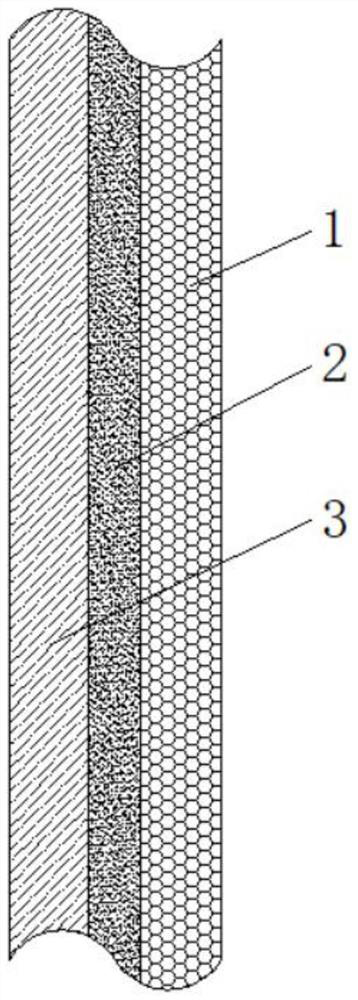

Unmanned aerial vehicle exterior paint-sprayed part surface decoration film and preparation method and application thereof

A surface decoration, drone technology, used in rayon manufacturing, heat activated film/sheet, film/sheet adhesive, etc., can solve the problems of drone damage, loss, inability to high temperature and thunderstorm protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

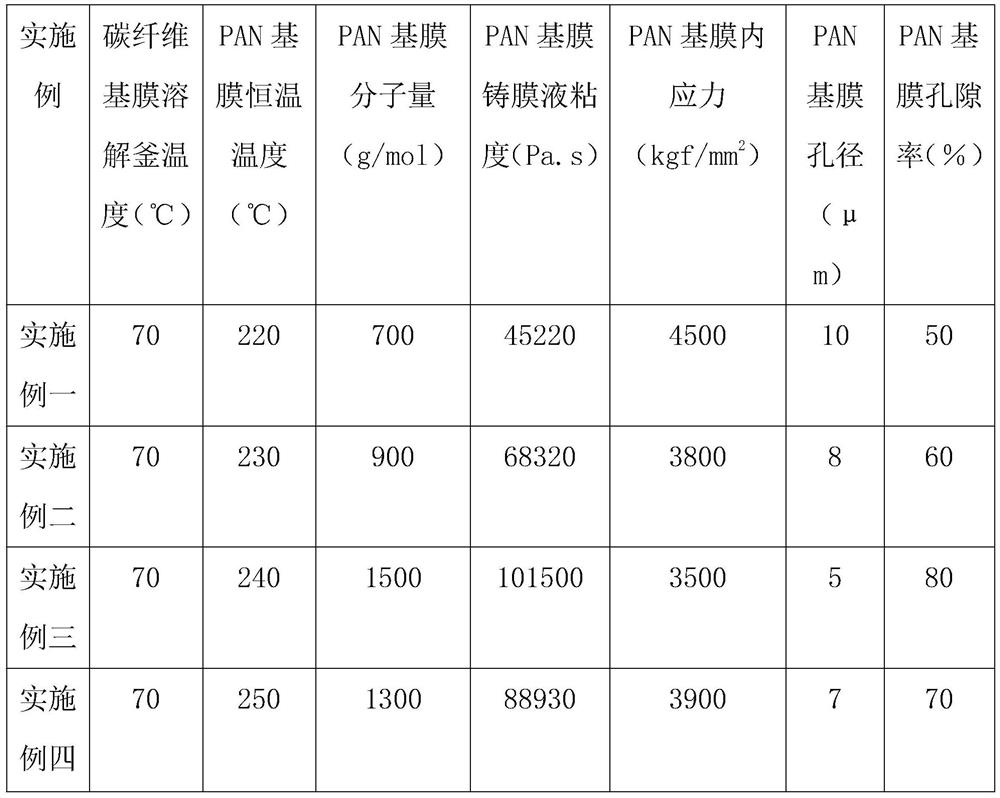

Embodiment 1

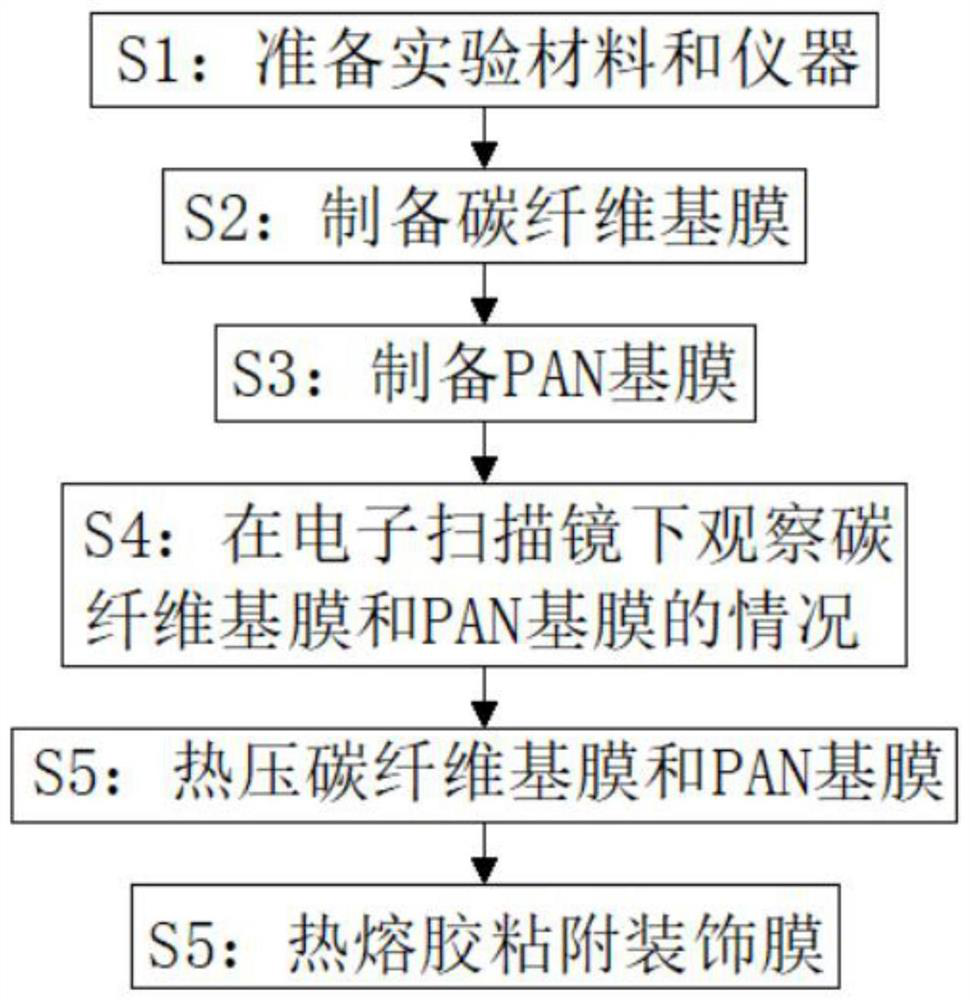

[0047] A surface decorative film for the exterior of an unmanned aerial vehicle and its preparation method and application, comprising the following steps:

[0048] Step 1: Prepare the materials and experimental instruments required for the experiment;

[0049] Step 2: Heat polyacrylonitrile, N,N-dimethylacetamide, polyvinyl pyrrolidone, polyimide YJ-16 and polymethyl methacrylate in a dissolving tank to 70°C according to the ratio, Dissolve for 4-6 hours, then stand for degassing for 24 hours and perform dry-wet spinning at room temperature to obtain a carbon fiber base film;

[0050] Step 3: Fix the two ends of the PAN base film and put it into the furnace, and pass in air for pre-oxidation treatment. The heating rate is 8°C / min. After the temperature rises to 220°C, it is kept at a constant temperature. The carbonization is maintained at a fixed length in a high-purity nitrogen atmosphere. Under the circumstances, obtain the PAN base film;

[0051] Step 4: Take out the ca...

Embodiment 2

[0064] A surface decorative film for the exterior of an unmanned aerial vehicle and its preparation method and application, comprising the following steps:

[0065] Step 1: Prepare the materials and experimental instruments required for the experiment;

[0066] Step 2: Heat polyacrylonitrile, N,N-dimethylacetamide, polyvinyl pyrrolidone, polyimide YJ-16 and polymethyl methacrylate in a dissolving tank to 70°C according to the ratio, Dissolve for 4-6 hours, then stand for degassing for 24 hours and perform dry-wet spinning at room temperature to obtain a carbon fiber base film;

[0067] Step 3: Fix the two ends of the PAN base film and put it in the furnace, and let air in for pre-oxidation treatment. The heating rate is 8°C / min. After the temperature rises to 230°C, it is kept at a constant temperature. Under the circumstances, obtain the PAN base film;

[0068] Step 4: Take out the carbon fiber base film and the PAN base film, and after standing at room temperature for 2-4 ...

Embodiment 3

[0081] A surface decorative film for the exterior of an unmanned aerial vehicle and its preparation method and application, comprising the following steps:

[0082] Step 1: Prepare the materials and experimental instruments required for the experiment;

[0083] Step 2: Heat polyacrylonitrile, N,N-dimethylacetamide, polyvinyl pyrrolidone, polyimide YJ-16 and polymethyl methacrylate in a dissolving tank to 70°C according to the ratio, Dissolve for 4-6 hours, then stand for degassing for 24 hours and perform dry-wet spinning at room temperature to obtain a carbon fiber base film;

[0084] Step 3: Fix the two ends of the PAN base film and put it into the furnace, and pass in air for pre-oxidation treatment. The heating rate is 8°C / min. After the temperature rises to 240°C, it is kept at a constant temperature. The carbonization is maintained at a fixed length in a high-purity nitrogen atmosphere. Under the circumstances, obtain the PAN base film;

[0085] Step 4: Take out the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com