Mold surface strengthening treatment process and system

A surface strengthening and treatment system technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve problems such as oil pollution, product shape and quality not up to standard, oxidation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

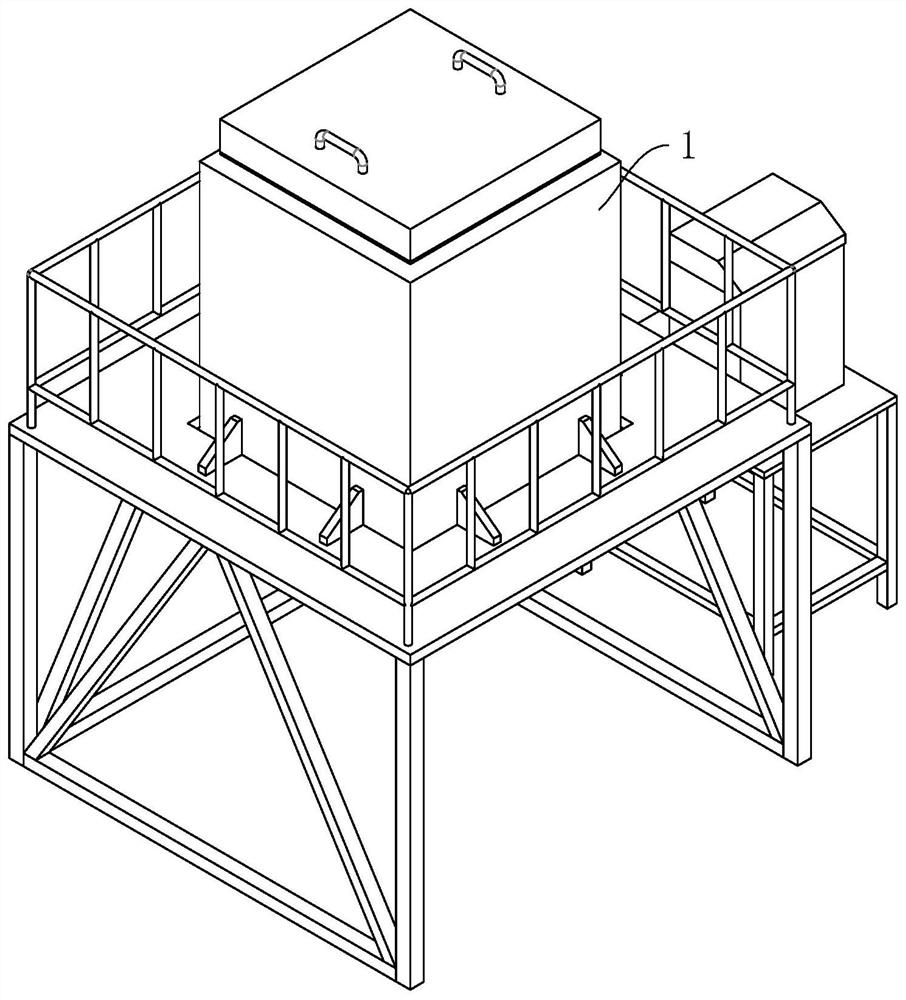

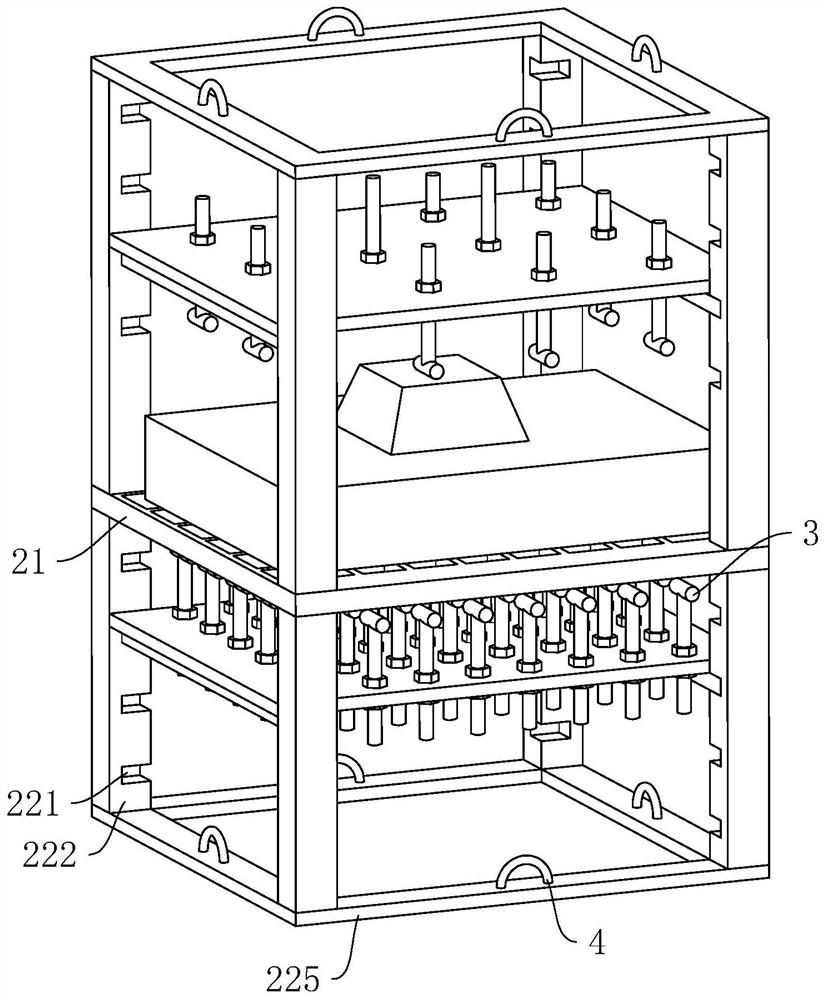

[0040] The following is attached Figure 1-4 The application is described in further detail.

[0041] The embodiment of the present application discloses a mold surface strengthening treatment process and system.

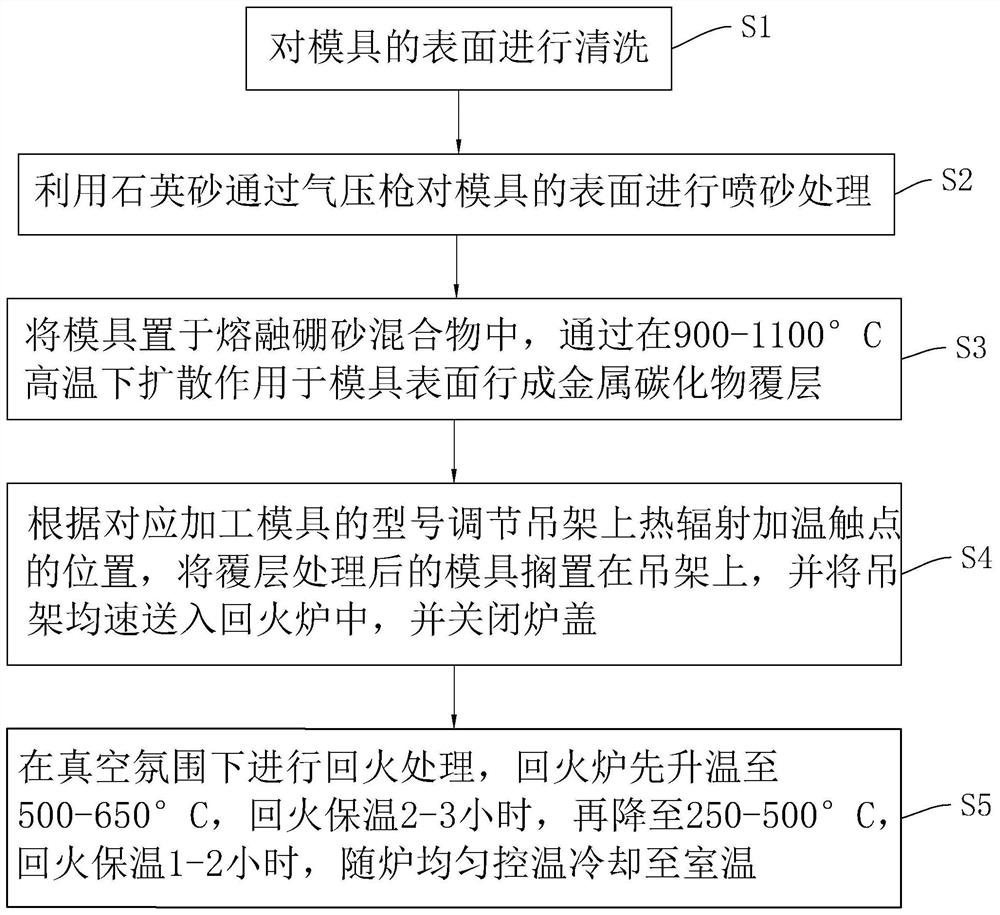

[0042] refer to figure 1 , mold surface strengthening treatment process and system, including the following steps:

[0043] S1, cleaning the surface of the mold with a strong cleaning solvent of Methacron to remove surface impurities;

[0044] S2, using quartz sand to blast the surface of the mold with an air gun, sandblasting the mold in a dry and non-liquid medium, and removing rust, scale, and oil on the surface of the mold to enhance surface adhesion Effect;

[0045] S3, the mold is placed in the molten borax mixture, and the metal carbide coating is formed on the surface of the mold by diffusion at a high temperature of 900-1100 ° C. The metal carbide coating can be carbide of vanadium, chromium, tantalum or titanium, A layer of high-hardness metal carbide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com