Hydroformylation catalyst composition for preparing 2-methylbutyraldehyde, method and application

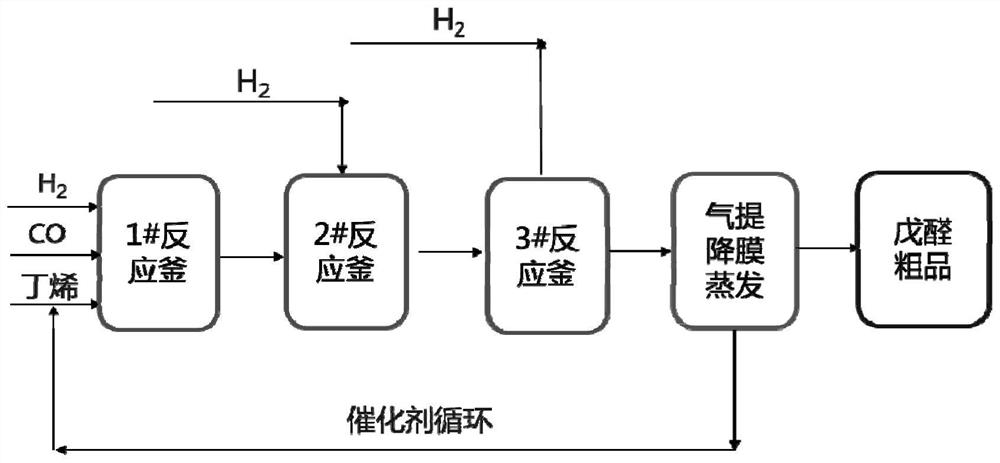

A hydroformylation catalyst, methyl butyraldehyde technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of 2-methylbutyraldehyde Unable to achieve intermittent response and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

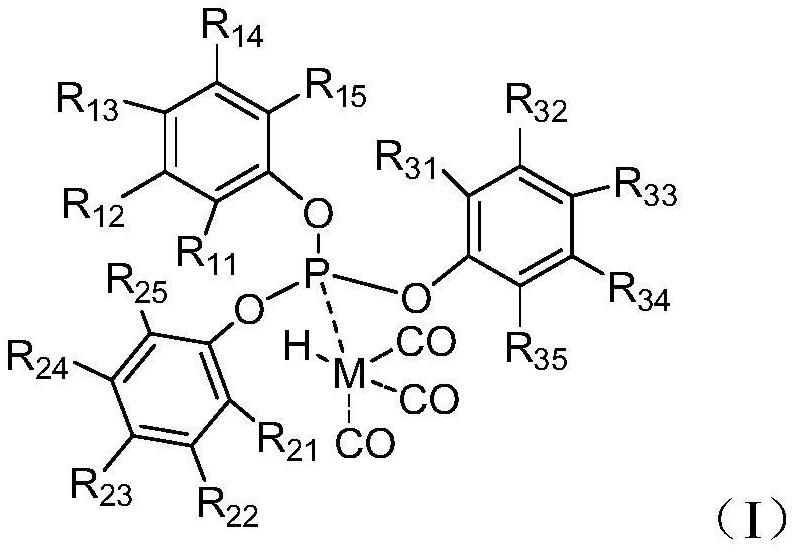

[0054] The preparation method of the monodentate complex of the present invention is not particularly limited, and may be a conventional production method known in the art. In an example of the present invention, the preparation method comprises dissolving the ligand (such as ligand L-3) and the metal compound (such as rhodium dicarbonyl acetylacetonate) in a solvent (such as toluene, valeraldehyde, etc.) according to a certain ratio, Added to the autoclave. After passing through synthetic gas for replacement (for example, replacement 3 times), pressurize (for example, pressurize to 1-2, preferably 1.5MPaG), heat the reaction (for example, heat to 60-90°C, preferably 80°C for 0.5-2 hours , preferably 1 hour), that is to form a monodentate complex (such as monodentate complex I-3).

[0055] In one example of the present invention, suitable solvents are neutral solvents such as benzene, toluene, xylene or mixtures thereof, and the like.

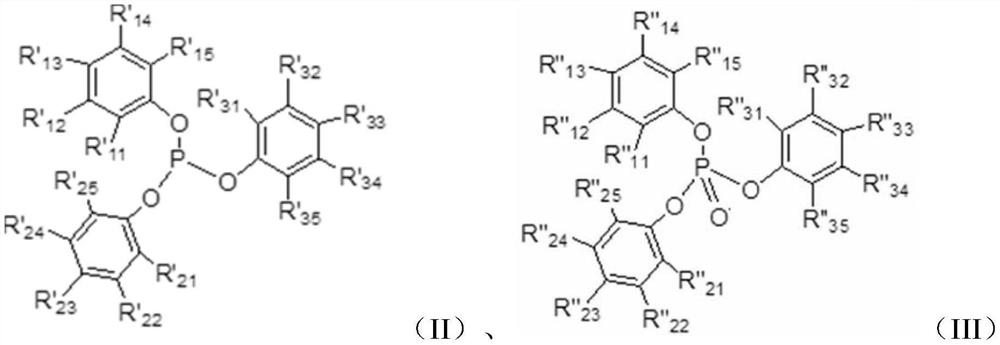

[0056] b) Free monophosphite (or monod...

Embodiment 1

[0116] A toluene solution of the catalyst composition is provided, the solution comprising the following components:

[0117]

[0118] Wherein, the molar ratio of Rh / P is 1:18, the molar concentration of Rh is 80ppm, and the molar ratio of rhodium complex and free phosphite ligand is 1:5.

[0119] Add 100g of the above-mentioned catalyst composition solution to a 200mL stainless steel autoclave equipped with a pressure gauge, replace the gas in the kettle with synthesis gas (the molar ratio of hydrogen:carbon monoxide is about 1:1) three times, add 10g of 1-butene, and use an electromagnetic Stir with a driven mechanical stirrer, feed the synthesis gas to the kettle pressure of 0.5 MPaG, heat up to 80°C inside the kettle, feed the synthesis gas until the total pressure is 1.5 MPaG, and maintain the temperature and pressure in the kettle to react at 0.5 Discharge after h.

[0120] Calculated on the basis of 1-butene, the conversion rate is 98%, the total selectivity of the ...

Embodiment 2

[0122] A toluene solution of the catalyst composition is provided, the solution comprising the following components:

[0123]

[0124] Wherein, the molar ratio of Rh / P is 1:18, the molar concentration of Rh is 80ppm, and the molar ratio of rhodium complex and free phosphite ligand is 1:3.

[0125] Add 100 g of the toluene solution of the above catalyst composition to a 200 mL stainless steel autoclave equipped with a pressure gauge. After replacing the gas in the kettle with synthesis gas (the molar ratio of hydrogen:carbon monoxide is about 1:1) three times, add 10 g of mixed butenes (70% by weight of 1-butene, 20% by weight of 2-butene, and 10% by weight of butane % by weight), stir with an electromagnetically driven mechanical stirrer, feed the synthesis gas to the kettle pressure of 0.5MPaG, heat up to 80°C in the kettle, feed the synthesis gas to the total pressure of 2.0MPaG, and keep the kettle The internal temperature and pressure reacted for 0.4h and then discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com