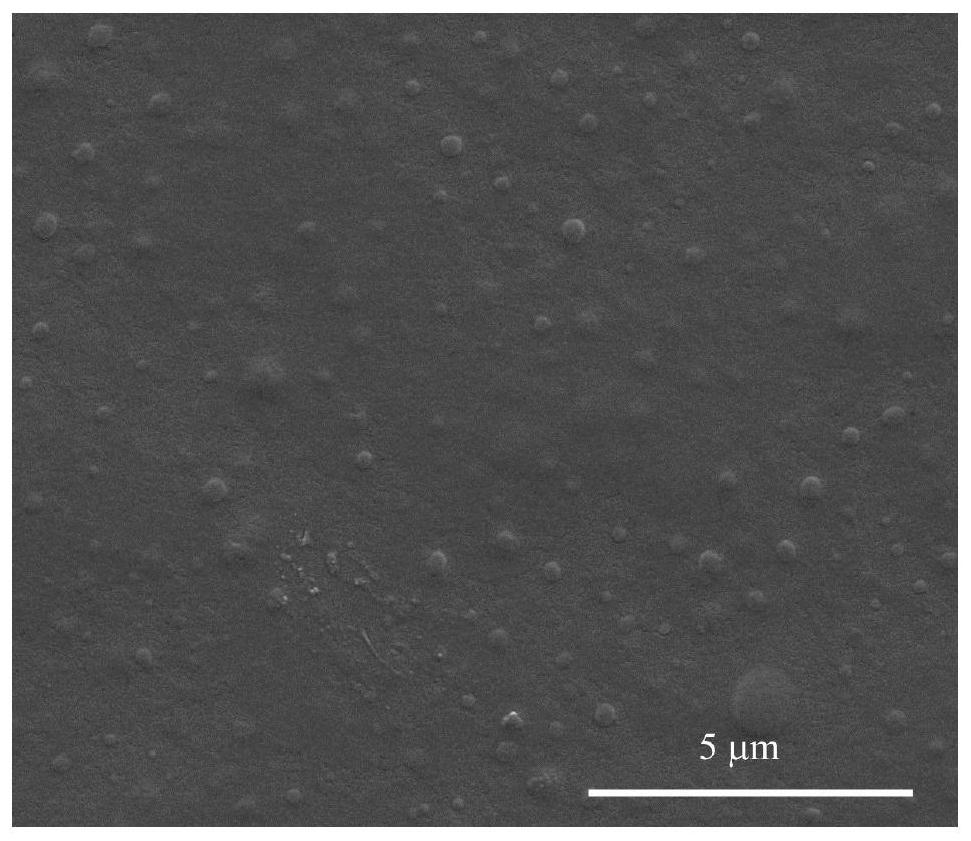

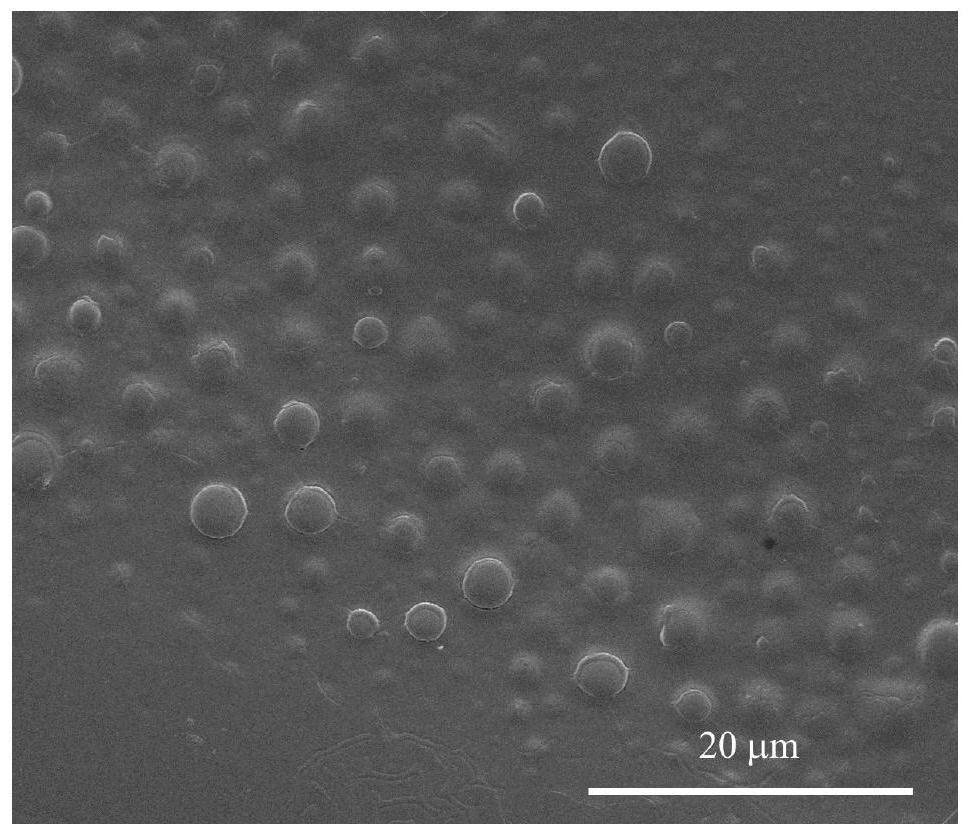

Composite material imitating desert beetle structure and preparation method of composite material

A technology of composite materials and beetles, applied to special surfaces, devices for coating liquids on surfaces, coatings, etc., can solve problems such as weak adhesion and poor structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] step 1:

[0065] Prepare the substrate layer: pretreat the cleaned and dried polyethylene substrate with 50V air plasma for 60s, and set aside;

[0066] Prepare the first solution: 3-Aminopropyltriethoxysilane hydrophobizing agent and absolute ethanol were magnetically heated and stirred in a water bath with a temperature of 30°C and a stirring rate of 1000r / min for 30min to prepare a solution with a mass concentration of 0.1%. Solution, namely obtain the first solution, standby.

[0067] Prepare the second solution: add polyacrylamide with an average molecular weight of 8,000,000 g / mol and water-based polyurethane to the second solvent; control the mass concentration of polyacrylamide to 0.5%, and control the mass fraction of water-based polyurethane to 0.05%. The second solvent is a second solvent formed of acetone and deionized water with a mass concentration of 70.0%. In a water bath at a temperature of 90° C. and a stirring rate of 2000 r / min, the mixture was mag...

Embodiment 2

[0074] step 1:

[0075] Prepare the substrate layer: pretreat the cleaned and dried polyethylene terephthalate substrate with 100V air plasma for 30s, and set aside;

[0076] Prepare the first solution: γ-glycidyl etheroxypropyl trimethoxysilane hydrophobic agent and absolute ethanol were magnetically heated and stirred in a water bath with a temperature of 40°C and a stirring rate of 1500r / min for 10 minutes to prepare a mass concentration of 0.5% solution, to obtain the first solution, for subsequent use;

[0077] Prepare the second solution: add polyvinyl alcohol with an average molecular weight of 720000 g / mol and water-based epoxy resin into the second solvent. The mass concentration of polyvinyl alcohol is controlled to be 2.0%, and the mass fraction of water-based epoxy resin is controlled to be 0.2%. The second solvent is a second solvent formed of ethanol and deionized water with a mass concentration of 60.0%. Magnetically heated and stirred in a water bath with a ...

Embodiment 3

[0084] step 1:

[0085] Prepare the substrate layer: pretreat the cleaned and dried polychlorinated p-xylylene material with 150V air plasma for 15s, and set aside;

[0086]Prepare the first solution: magnetically heat and stir γ-methacryloxypropyltrimethoxysilane hydrophobic agent with a mass concentration of 1.0% and absolute ethanol in a water bath at a temperature of 30°C and a stirring rate of 1500r / min Disperse for 20 minutes to obtain the first solution and set aside;

[0087] Prepare the second solution: add polyethylene glycol and water-based polyurethane to the second solvent, heat in a water bath at 50°C, and disperse with magnetic stirring for 90 minutes at a stirring rate of 1200 r / min to obtain the second solution. The second solvent is a mixed solvent composed of N,N-dimethylformamide and deionized water with a mass concentration of 50.0%. Control the mass concentration of polyethylene glycol in the second solution to be 5.0%, and the mass fraction of water-ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com