Clear liquid type organic high nitrogen fertilizer and preparation method thereof

A high-nitrogen fertilizer and organic technology, applied in nitrogen fertilizer, inorganic fertilizer, liquid fertilizer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

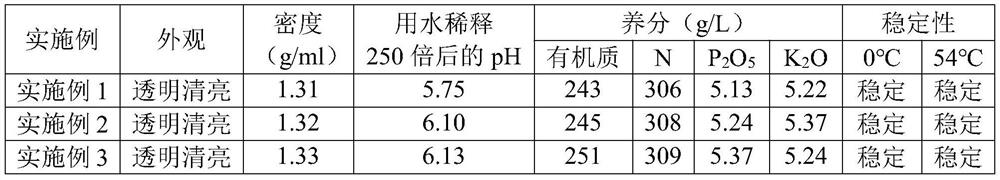

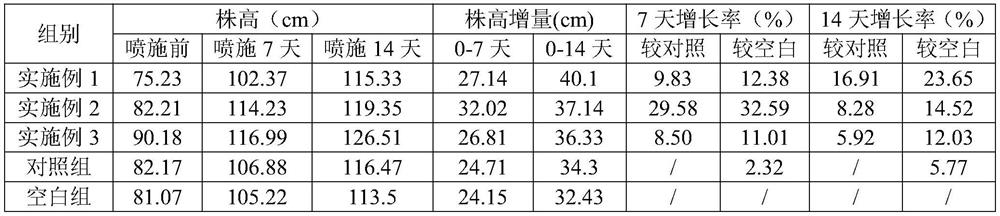

Embodiment 1

[0022] A preparation method of clear liquid type organic high-nitrogen fertilizer, comprising the following steps:

[0023] (1) Take 16.5 parts of pure water, add it to the reaction kettle, turn on the agitator, slowly add 0.5 parts of potassium hydroxide and 0.5 parts of citric acid, and stir for 60 minutes at a speed of 40 r / min until the two react completely;

[0024] (2) Take 26.5 parts of urea and 22 parts of polyethylene glycol, add them into the reaction kettle, stir at a speed of 40r / min for 60min, then add 33.5 parts of ammonium nitrate, and continue stirring for 60min until no visible substances appear;

[0025] (3) Take 0.5 part of 85% phosphoric acid and add it to the reaction kettle, turn on the heating equipment of the reaction kettle, control the reaction temperature to 40° C., and stir for 2 hours at a speed of 40 r / min until the reaction is complete and the solution system is stable;

[0026] (4) Let the materials in the reactor stand for 2 hours to normal tem...

Embodiment 2

[0028] A preparation method of clear liquid type organic high-nitrogen fertilizer, comprising the following steps:

[0029] (1) Take 14.3 parts of pure water, add it to the reaction kettle, start the agitator, slowly add 0.6 parts of potassium hydroxide, 0.275 parts of citric acid, and 0.275 parts of homoisocitric acid, and stir for 45 minutes at a speed of 50 r / min until the reaction completely;

[0030] (2) Take 26.95 parts of urea, 7.5 parts of polyethylene glycol, 7.5 parts of polypropylene glycol, and 7.5 parts of polyglycerol, add them to the reaction kettle, stir at a speed of 50r / min for 45min, then add 34 parts of ammonium nitrate, and continue stirring 45min, until no visible substance appears;

[0031] (3) Add 0.6 parts of 85% phosphoric acid into the reactor, turn on the heating equipment of the reactor, control the reaction temperature to 40° C., and stir for 1.5 hours at a speed of 50 r / min until the reaction is complete and the solution system is stable;

[00...

Embodiment 3

[0034] A preparation method of clear liquid type organic high-nitrogen fertilizer, comprising the following steps:

[0035] (1) Take 11 parts of pure water, add it to the reaction kettle, start the agitator, slowly add 0.7 parts of potassium hydroxide, 0.45 parts of isocitric acid, and 0.2 parts of high citric acid, and stir for 30 minutes at a speed of 60 r / min until the reaction completely;

[0036] (2) Take 27.5 parts of urea and 24 parts of polyglycerol, add them to the reaction kettle, stir for 30 minutes at a speed of 60 r / min, then add 35.5 parts of ammonium nitrate, and continue stirring for 30 minutes until no visible substances appear;

[0037] (3) Add 0.65 parts of 85% phosphoric acid into the reactor, turn on the heating equipment of the reactor, control the reaction temperature to 40° C., and stir for 1 hour at a speed of 60 r / min until the reaction is complete and the solution system is stable;

[0038] (4) Let the materials in the reactor stand for 2 hours to nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com