Preparation method of sacubitril

A technology of sacubitril and compounds, which is applied in the field of preparation of sacubitril and its intermediates and chiral prosthetic groups, can solve the problems of high waste liquid treatment cost, low ratio of diastereoisomers, high production cost, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

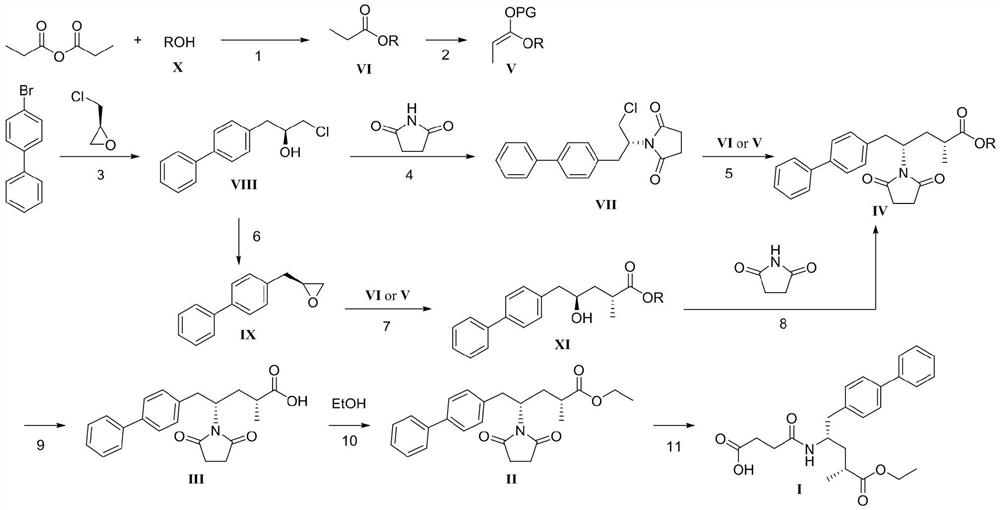

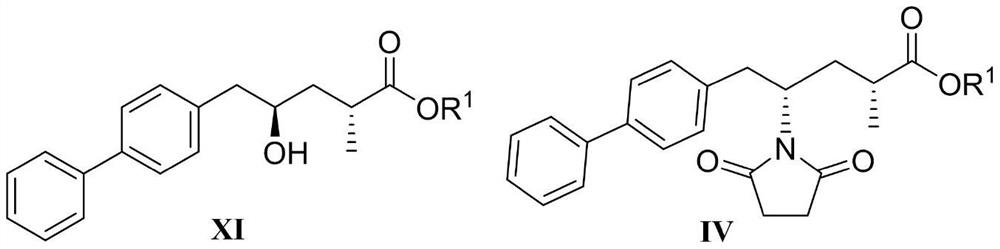

Method used

Image

Examples

Embodiment 1

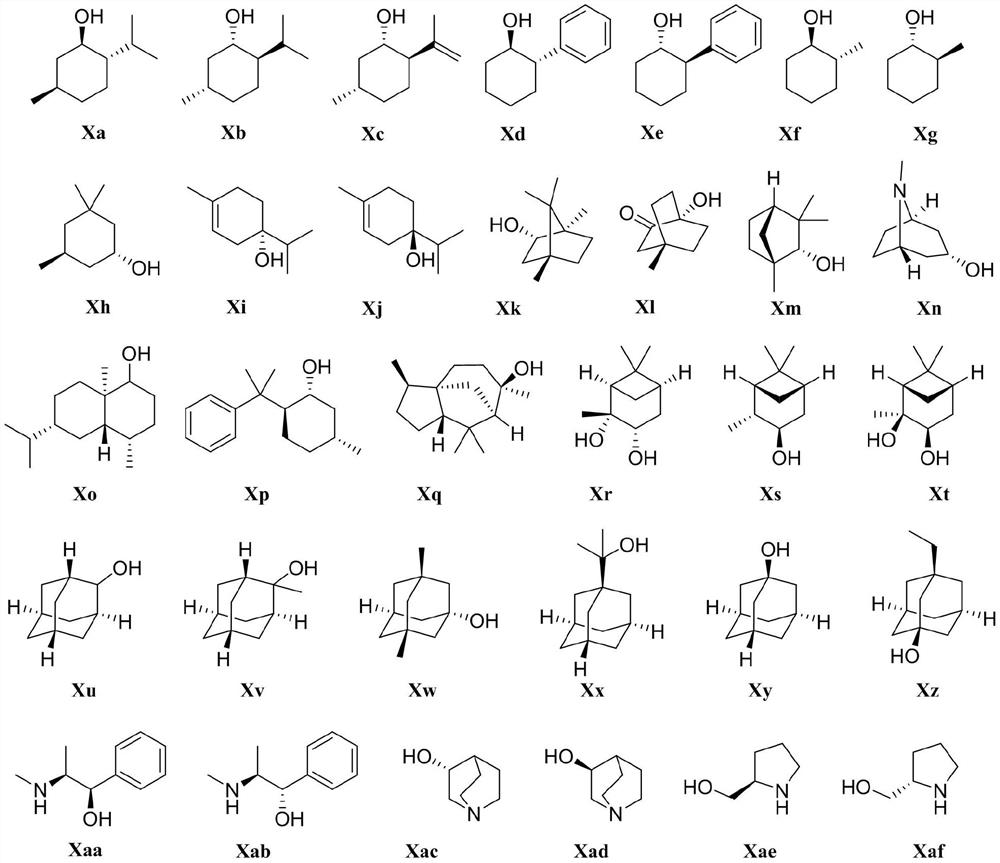

[0109] Embodiment 1: Preparation of (1R, 2S, 5R)-2-isopropyl-5-methylcyclohexyl propionate (formula VIa)

[0110]

[0111] Add L-Menthol (20g, formula Xa), DMAP (80mg) in the round bottom flask (100mL), stir at room temperature, then add propionic anhydride (18.3g), continue to stir for 10 hours. Distillation under reduced pressure gave the compound of formula VIa (26.5 g, 98%).

[0112] Tested: 1 H NMR (400MHz, CDCl 3 )δ (ppm) 0.76 (d, J = 7.0Hz, 3H), 0.88 (d, J = 2.2Hz, 3H), 0.92 (d, J = 1.6Hz, 3H), 0.99-1.05 (m, 2H), 1.06-1.10(m,1H),1.14(t,J=7.6Hz,3H),1.35-2.00(m,6H),2.31(q,J=7.6Hz, 2H),4.70(dd,J=10.8, 4.4Hz, 1H).

Embodiment 2

[0113] Example 2: Preparation of (1S, 2R, 5S)-2-isopropyl-5-methylcyclohexyl propionate (formula VIb)

[0114]

[0115] Add D-Menthol (20g, formula Xb), DMAP (80mg) in the round bottom flask (100mL), stir at room temperature, then add propionic anhydride (18.3g), continue to stir for 10 hours. Distillation under reduced pressure gave the compound of formula VIb (26.4 g, 97%).

Embodiment 3

[0116] Embodiment 3: Preparation of (1R, 2S)-2-phenylcyclohexyl propionate (formula VId)

[0117]

[0118] Add (1R,2S)-2-phenylcyclohexyl-1-alcohol (20g, formula Xd), DMAP (80mg) in the round bottom flask (100mL), stir at room temperature, then add propionic anhydride (16g), continue to stir for 10 Hour. Distillation under reduced pressure gave the compound of formula VId (24.2 g, 92%).

[0119] Tested: 1 H NMR (400MHz, CDCl 3 )δ (ppm) 0.85 (t, J = 7.5Hz, 3H), 1.30-1.66 (m, 4H), 1.72-2.10 (m, 6H), 2.66 (dt, J = 4.4, 11.4Hz, 1H), 4.95 (dt, J=4.4, 10.5Hz, 2H), 7.11-7.25 (m, 5H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com