Novel PME plastic

A new type of plastic technology, applied in the field of PME plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Further, the preparation method of described novel PME plastic comprises the following steps:

[0041] S1, send the PC masterbatch and UHMWPE ultra-high molecular polyethylene into a vacuum drying oven respectively, and dry them in vacuum. Hourly rise 7°C until the temperature reaches 118°C, then send the dried PC masterbatch and UHMWPE ultra-high molecular polyethylene into the heating box, the heating temperature is 90°C ~ 93°C, after baking for 4.5h ~ 5h , take out the spare;

[0042] S2, Put the baked PC masterbatch, UHMWPE ultra-high molecular polyethylene and other raw materials into a high-speed mixer for mixing treatment to obtain a mixture. The temperature of the mixing treatment is 140 ° C ~ 145 ° C, and the duration of the mixing treatment is 18 minutes ~23min, put the mixture into the reaction kettle, seal it and replace it with nitrogen gas for 8~9 times, heat to react, the reaction pressure is 3.0MPa~3.1MPa, the reaction temperature is 210℃~218℃, and the ...

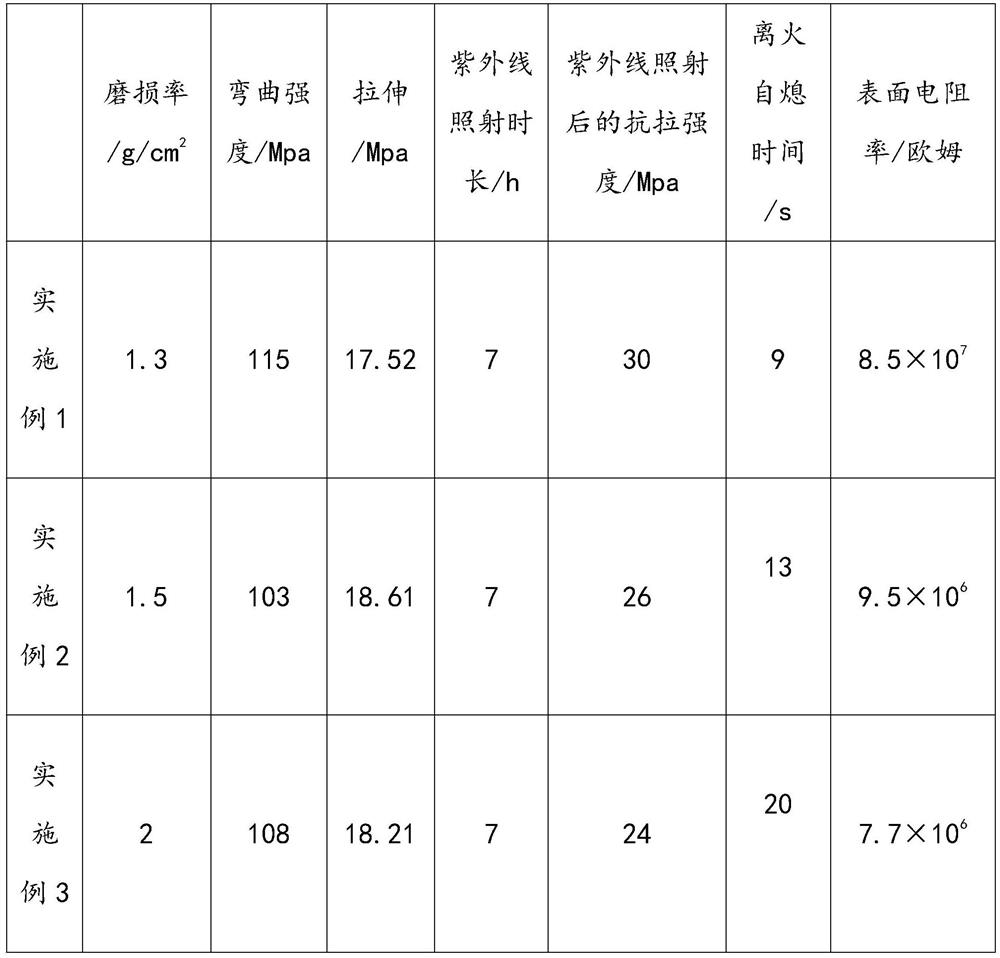

Embodiment example 1

[0062] Calcium carbonate, glycerin, hydroxypropyl methylcellulose ether, diatomaceous earth, propylene glycol and xylitol are mixed according to the mass ratio of 3:2:1:2:1:3 to make plastic additives, and then carbon black, Carbon fiber and medium-alkali glass fiber are mixed according to the mass ratio of 1:1:2 to make antistatic agent;

[0063] Add pentane solvent to the reaction kettle, then add 130 parts of propylene, 7 parts of triethylaluminum and 13.5 parts of methylalumoxane in sequence, stir evenly, and then continuously feed ethylene to carry out one-stage polymerization reaction. The temperature of one-stage polymerization reaction is 100°C, pressure 2.5MPa, time 4.5h, the product obtained from the first-stage polymerization reaction and 55 parts of 1-butene, 10 parts of nano-metal powder and 3 parts of fluorescent powder were subjected to a second-stage polymerization reaction, and the temperature of the second-stage polymerization reaction was 90°C , pressure 1.8...

Embodiment example 2

[0068] Calcium carbonate, glycerin, hydroxypropyl methylcellulose ether, diatomaceous earth, propylene glycol and xylitol are mixed according to the mass ratio of 3:2:1:2:1:3 to make plastic additives, and then carbon black, Carbon fiber and medium-alkali glass fiber are mixed according to the mass ratio of 1:1:2 to make antistatic agent;

[0069] Add pentane solvent to the reaction kettle, then add 130 parts of propylene, 7 parts of triethylaluminum and 13.5 parts of methylalumoxane in sequence, stir evenly, and then continuously feed ethylene to carry out one-stage polymerization reaction. The temperature of one-stage polymerization reaction is 100°C, pressure 2.5MPa, time 4.5h, the product obtained from the first-stage polymerization reaction and 55 parts of 1-butene, 10 parts of nano-metal powder and 3 parts of fluorescent powder were subjected to a second-stage polymerization reaction, and the temperature of the second-stage polymerization reaction was 90°C , pressure 1.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com