High-durability asphalt cold patch material and preparation method thereof

A technology for cold patching materials and asphalt, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of poor water resistance, dispersion, and poor cohesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

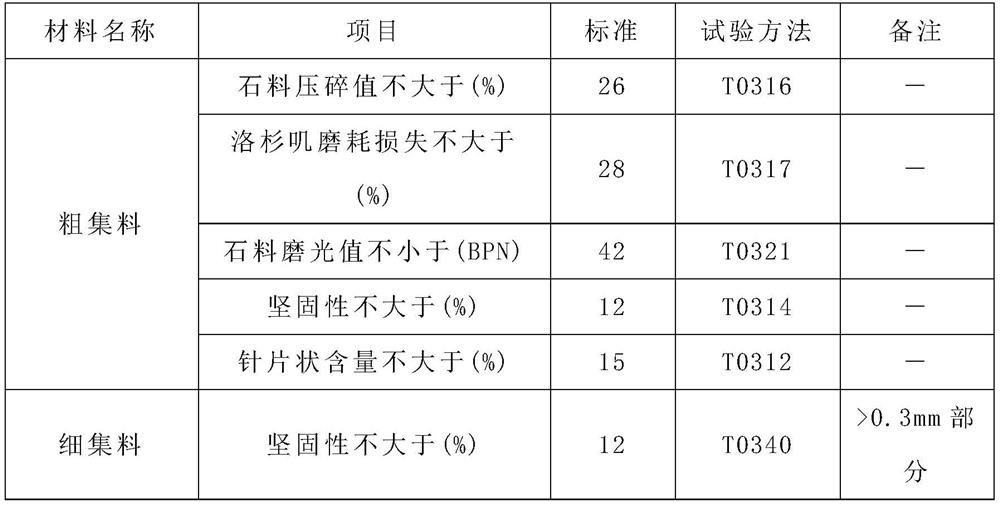

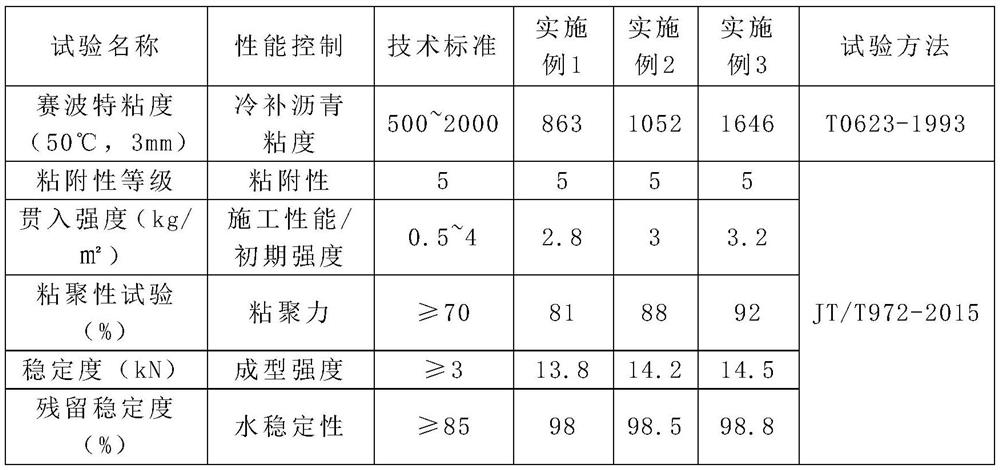

[0040] An asphalt cold replenishment liquid is composed of the following raw materials in parts by mass: petroleum asphalt: 69 parts; SBS thermoplastic styrene-butadiene rubber: 5 parts; diesel oil: 24 parts; additives: 2 parts. The petroleum asphalt is 90# petroleum asphalt with a viscosity of not less than 180Pa.s at 60°C, the SBS thermoplastic styrene-butadiene rubber is YH-791 produced by Sinopec, the diesel is -20# diesel, and the additives are mineral oil, aviation kerosene, C5 petroleum Resin and C9 petroleum resin are composed according to the mass ratio of 5:4:1:1, and the additives are prepared by the following method: take aviation kerosene and mineral oil and add them to a high-speed shearing machine, heat up to 60°C to 80°C, and then add C5 petroleum resin and C9 petroleum resin, after continuing to heat up to 80°C-90°C, start the high-speed shearing machine to cut for 30min-40min to prepare the additive. The technical characteristics of the additive are shown in T...

Embodiment 2

[0048] An asphalt cold replenishment liquid is composed of the following raw materials in parts by mass: petroleum asphalt: 76 parts; SBS thermoplastic styrene-butadiene rubber: 4 parts; diesel oil: 18.5 parts; additives: 1.5 parts. Among them, petroleum asphalt is 90# petroleum asphalt with a viscosity of not less than 180Pa.s at 60°C, SBS thermoplastic styrene-butadiene rubber is YH-791 produced by Sinopec, diesel is -10# diesel, and the additives are mineral oil, aviation kerosene, C5 petroleum Resin and C9 petroleum resin are composed according to the mass ratio of 5:4:1:1, and the additives are prepared by the following method: take aviation kerosene and mineral oil and add them to a high-speed shearing machine, heat up to 60°C to 80°C, and then add C5 petroleum resin and C9 petroleum resin, after continuing to heat up to 80°C-90°C, start the high-speed shearing machine to cut for 30min-40min to prepare the additive. The technical characteristics of the additive are shown ...

Embodiment 3

[0056] An asphalt cold replenishment liquid is composed of the following raw materials in parts by mass: petroleum asphalt: 83 parts; SBS thermoplastic styrene-butadiene rubber: 3 parts; diesel oil: 13 parts; additives: 1 part. The petroleum asphalt is 90# petroleum asphalt with a viscosity of not less than 180Pa.s at 60°C, the SBS thermoplastic styrene-butadiene rubber is YH-791 produced by Sinopec, the diesel is 0# diesel, and the additives are mineral oil, aviation kerosene, and C5 petroleum resin. and C9 petroleum resin according to the mass ratio of 5:4:1:1. The additives are prepared by the following method: take aviation kerosene and mineral oil and add them to a high-speed shearing machine. After heating up to 60°C to 80°C, add C5 petroleum resin and C9 petroleum resin, after continuing to heat up to 80°C-90°C, start the high-speed shearing machine to cut for 30min-40min to prepare the additive. The technical characteristics of the additive are shown in Table 1.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com