A preparation method of a stable liquid impact resistant superamphiphobic coating

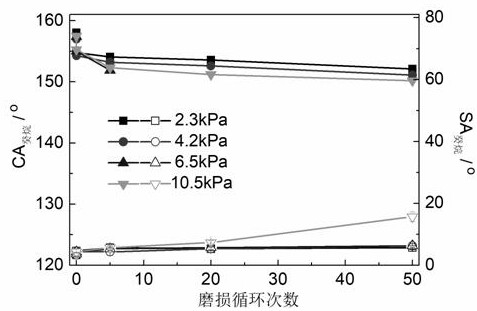

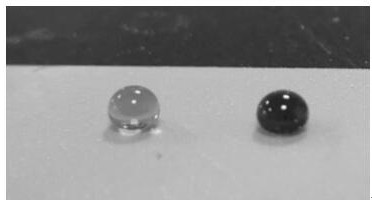

A liquid-resistant, super-amphiphobic technology, applied in coatings and other directions, can solve problems such as poor mechanical stability and poor resistance to low surface tension liquid impact, achieve excellent liquid impact resistance, improve liquid impact resistance, and increase contact resistance. The effect of branch density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

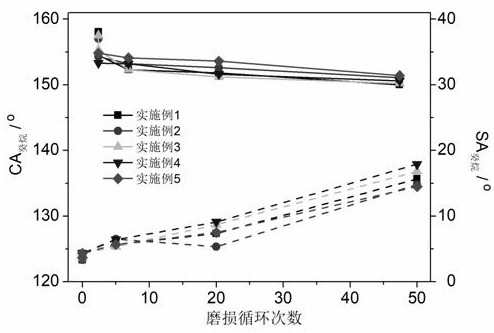

Examples

Embodiment 1

[0035] (1) Prepare an acetone solution with a mass fraction of 1% α-butyl cyanoacrylate, and spray the solution onto the surface of the glass substrate, and control the relative humidity of the environment to 40% for polymerization and steam-induced phase separation to obtain poly-α - butyl cyanoacrylate stabilizes the microstructure;

[0036] (2) Add 1mL of ammonia water to 50mL of ethanol solution and stir evenly, then put the polybutyl α-cyanoacrylate stabilized microstructure (substrate) into the solution, and then add 0.25g of tetraethyl orthosilicate dropwise, Stir continuously for 10 minutes, then add 0.25g (3-mercaptopropyl)trimethoxysilane dropwise, stir at room temperature for 12 hours, take it out, wash with ethanol, and finally place it in a drying oven at 60°C for 1 hour to obtain a mercaptolated micro-nano composite structural surface;

[0037] (3) Disperse 0.5g of 2-(perfluorodecyl)ethyl methacrylate into 50mL of ethanol solution, place the surface of the merca...

Embodiment 2

[0039] (1) Prepare a tetrahydrofuran solution of ethyl α-cyanoacrylate with a mass fraction of 2.5%, and spray the solution onto the surface of the ceramic substrate, and control the relative humidity of the environment at 50% for polymerization and steam-induced phase separation to obtain poly-α - Ethyl cyanoacrylate stabilizes the microstructure;

[0040](2) Add 0.5mL ammonia water to 50mL ethanol solution and stir evenly, then put poly-ethyl α-cyanoacrylate stabilized microstructure into the solution, then add 0.2g tetraethyl orthosilicate dropwise, and stir continuously for 30min. Add 0.2 g of (3-mercaptopropyl)trimethoxysilane dropwise, stir at room temperature for 18 hours, take out the substrate and wash it with ethanol, and finally place it in a drying oven at 70°C for 2 hours to obtain a mercaptolated micro-nano composite structure surface;

[0041] (3) Disperse 1.0g of 2-(perfluorodecyl)ethyl methacrylate into 50mL of ethanol solution, then place the surface of the t...

Embodiment 3

[0043] (1) A tetrahydrofuran solution of α-methyl cyanoacrylate with a mass fraction of 1.5% was prepared, and the solution was sprayed onto the surface of an aluminum alloy substrate, and the relative humidity of the environment was controlled at 70% for polymerization and steam-induced phase separation to obtain a polymer α-methyl cyanoacrylate stabilizes the microstructure;

[0044] (2) Add 2 mL of ammonia water to 50 mL of ethanol solution and stir evenly, then put poly-α-methyl cyanoacrylate stabilized microstructure into the solution, then add 0.6 g of tetraethyl orthosilicate dropwise, stir continuously for 10 min, and then Add 0.6g (3-mercaptopropyl)trimethoxysilane dropwise, stir at room temperature for 24 hours, take out the substrate and wash it with ethanol, and finally place it in a drying oven at 70°C for 2 hours to obtain a mercaptolated micro-nano composite structure surface;

[0045] (3) Disperse 1.5g of 2-(perfluorododecyl)ethyl methacrylate into 50mL of etha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com