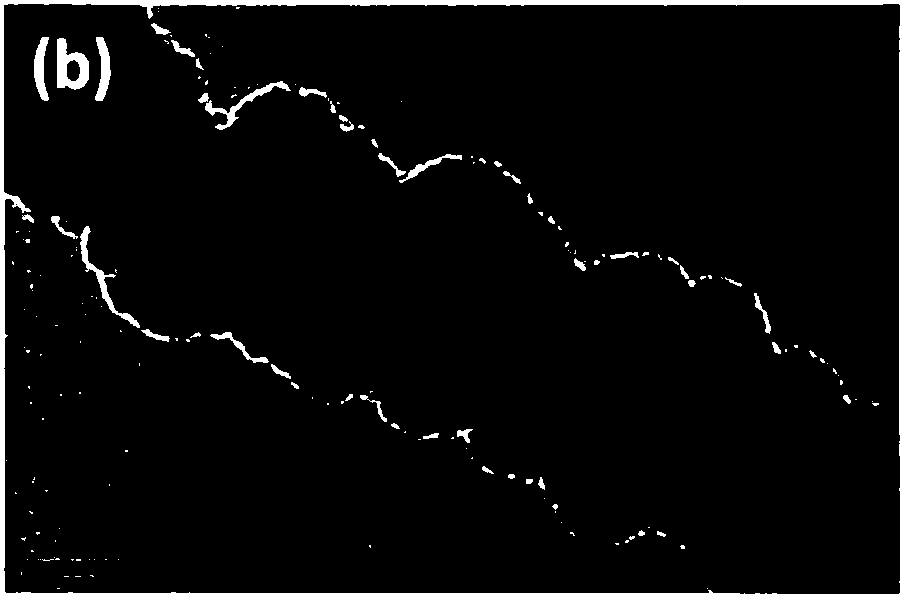

A preparation method of candied haws-shaped superamphiphobic composite material

A composite material and super-amphiphobic technology, which is applied in the field of preparation of super-amphiphobic composite materials, can solve problems such as poor stability and durability, cumbersome and complicated preparation process, and harsh reaction conditions, and achieve good fastness and simple preparation process , the effect that the conditions are easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing a candied fruit-shaped super-amphiphobic composite material, comprising the following steps:

[0023] 1) Add 0.05 parts of tellurium nanowires into 10 parts of absolute ethanol in parts by mass, and stir magnetically for 10 minutes;

[0024] 2) In parts by mass, add 0.1 part of ammonia water and 0.05 part of deionized water to the solution obtained in step 1), and continue stirring for 1 min;

[0025] 3) According to the number of parts by mass, add 12 parts of TEOS / absolute ethanol mixed solution with a volume ratio of (1:10) and 1 part of perfluorooctyltriethoxysilane dropwise to the above step 2) in sequence Add the obtained solution to the above solution, continue to stir for 1 hour after the completion of the dropwise addition, centrifuge wash with water and absolute ethanol respectively after the reaction, and then dry at 50°C to obtain the finished product.

Embodiment 2

[0027] A method for preparing a candied fruit-shaped super-amphiphobic composite material, comprising the following steps:

[0028] 1) Add 0.25 parts of tellurium nanowires into 17 parts of absolute ethanol in parts by mass, and stir magnetically for 40 minutes;

[0029] 2) In parts by mass, add 0.5 parts of ammonia water and 1 part of deionized water to the solution obtained in step 1), and continue stirring for 12 minutes;

[0030] 3) According to the number of parts by mass, add 21 parts of TEOS / absolute ethanol mixed solution with a volume ratio of (1:10) and 10 parts of perfluorooctyltriethoxysilane dropwise to the above step 2) in sequence The resulting solution, to the above solution. Continue to stir for 2 hours after the dropwise addition is completed, centrifuge wash with water and absolute ethanol respectively after the reaction, and then dry at 60°C to obtain the finished product.

Embodiment 3

[0032] A method for preparing a candied fruit-shaped super-amphiphobic composite material, comprising the following steps:

[0033] 1) Add 0.3 parts of tellurium nanowires into 25 parts of absolute ethanol in parts by mass, and stir magnetically for 80 minutes;

[0034] 2) In parts by mass, add 1 part of ammonia water and 2 parts of deionized water to the solution obtained in step 1), and continue stirring for 25 minutes;

[0035] 3) According to the number of parts by mass, add 30 parts of TEOS / absolute ethanol mixed solution with a volume ratio of (1:10) and 20 parts of perfluorooctyltriethoxysilane dropwise to the above step 2) in sequence Add the obtained solution to the above solution, continue to stir for 3 hours after the completion of the dropwise addition, centrifuge wash with water and absolute ethanol after the reaction, and then dry at 70°C to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com