An integrated wear-resistant fluorine-silicon-based superamphiphobic coating on the bottom surface and its preparation method and application

A super-amphiphobic, fluorosilicon technology, used in coatings, anti-corrosion coatings, etc., can solve the problems of complex preparation process, cumbersome maintenance process, poor wear resistance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

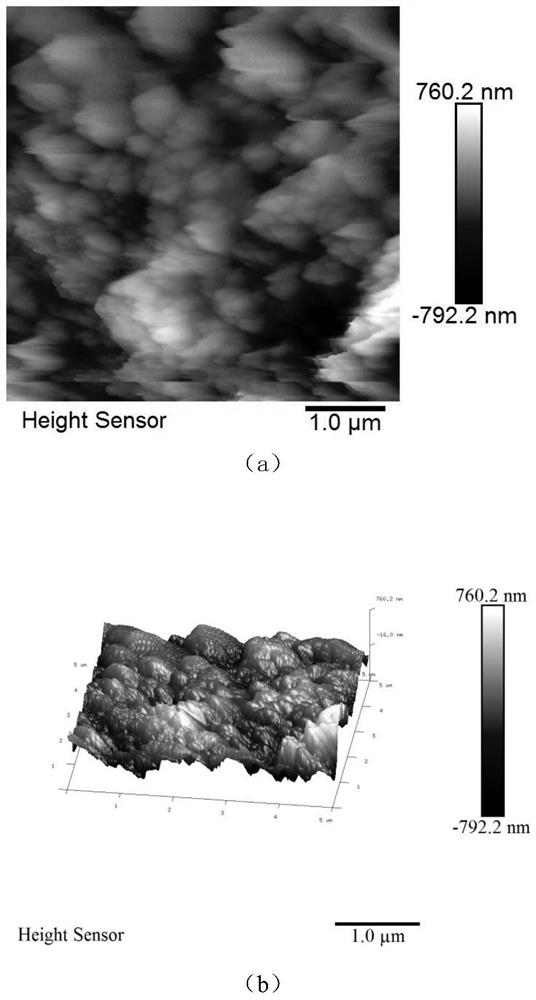

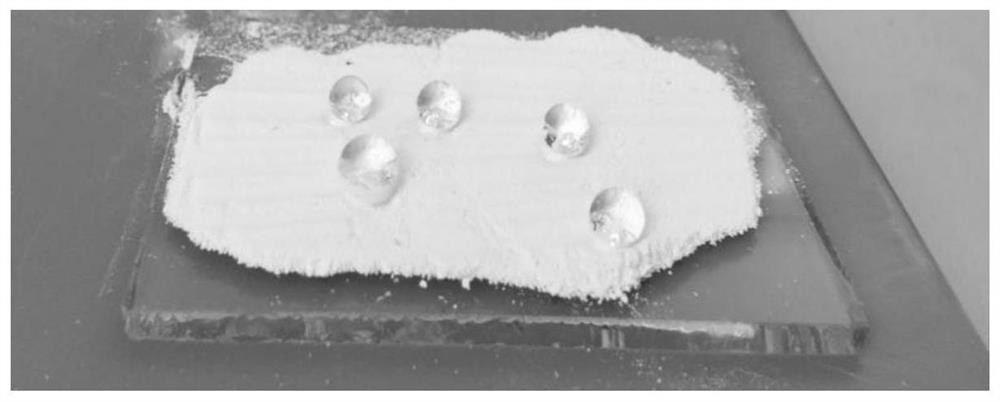

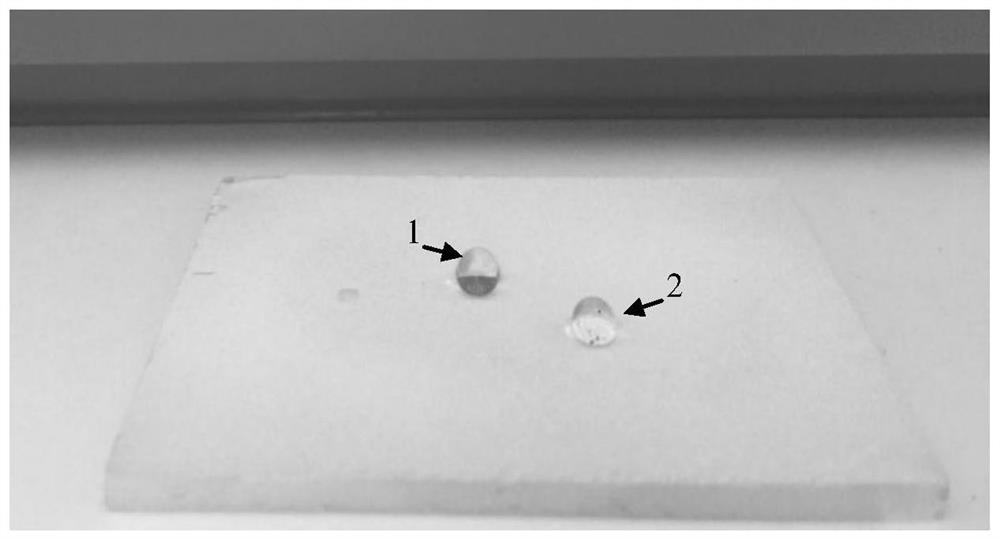

[0077] Example 1: Integrated wear-resistant fluorosilicone base-micro-nano SiO on the bottom surface 2 Preparation process of super amphiphobic coating

[0078] 1. Synergistic modification of micro-silica and nano-silica to obtain modified blended micro-nano SiO 2 particle.

[0079] (1) Preparation of blended ball-milled micro-nano powder: Weigh a certain amount of micron-sized SiO 2 with nanoscale SiO 2 The two kinds of particles are placed in a mixer and mixed evenly, and then placed in a planetary ball mill for 2 hours to obtain a blended ball-milled micro-nano powder.

[0080] (2) Pre-dispersion of blended micro-nano particles: Dissolve the blended ball-milled micro-nano powder in absolute ethanol, shear and disperse at a rate of 6krpm for 20min, switch to a low-speed mechanical stirring rate of 500rpm, add a small amount of surfactant DNS- 86, stirring for 20min.

[0081] (3) Pre-hydrolysis of the coupling agent: Dissolve dodecafluoroheptylpropyltrimethoxysilane in a...

Embodiment 2

[0094] Example 2: Integrated wear-resistant fluorosilicon-nano TiO on the bottom surface 2 -SiO 2 Preparation process of super amphiphobic coating

[0095] 1. Nano-TiO 2 with nano-SiO 2 Synergistic modification treatment to obtain modified TiO 2 -SiO 2 Nanoparticles

[0096] (1) Preparation of blended ball-milled micro-nano powder: Weigh a certain amount of nano-scale silicon dioxide and nano-scale titanium dioxide particles, mix them evenly in a mixer, and then place them in a planetary ball mill for 2 hours to obtain Blending and ball milling micro-nano powder. Nanoscale TiO 2 with nanoscale SiO 2 The weight ratio between particles is 1:2.

[0097] (2) Pre-dispersion of blended micro-nano particles: Disperse the blended ball-milled micro-nano powders in absolute ethanol, shear and disperse at a rate of 8krpm for 30min, switch to a low-speed mechanical stirring rate of 600rpm, add a small amount of surfactant DNS- 86, stirring for 25min.

[0098] (3) Pre-hydrolysis...

Embodiment 3

[0109] Example 3: Integrated wear-resistant fluorosilicon-nano-Al on the bottom surface 2 o 3 -SiO 2 Preparation process of super amphiphobic coating

[0110] 1. Nano Al 2 o 3 with nano-SiO 2 Synergistic modification treatment to obtain modified Al 2 o 3 -SiO 2 Nanoparticles

[0111] (1) Preparation of blended ball-milled micro-nano powder: take a certain amount of two kinds of particles of nano-scale silicon dioxide and nano-scale alumina, place them in a mixer and mix them evenly, place them in a mixer and mix them evenly, and then Place it in a planetary ball mill for ball milling for 2 hours to obtain a blended ball milled micro-nano powder. Nanoscale Al 2 o 3 with nanoscale SiO 2 The weight ratio between particles is 3:1.

[0112] (2) Pre-dispersion of blended micro-nano particles: Disperse the blended ball-milled micro-nano powders in absolute ethanol, shear and disperse at a rate of 8krpm for 30min, switch to a low-speed mechanical stirring rate of 600rpm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com