Combined heat and power generation system under ultrahigh temperature and ultrahigh pressure parameters

A cogeneration and ultra-high pressure technology, applied in lighting and heating equipment, separation methods, dispersed particle separation, etc., can solve the problem of reducing the dust removal efficiency of the bag filter, affecting the flue gas circulation efficiency, and the dust cannot quickly fall into the ash storage. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

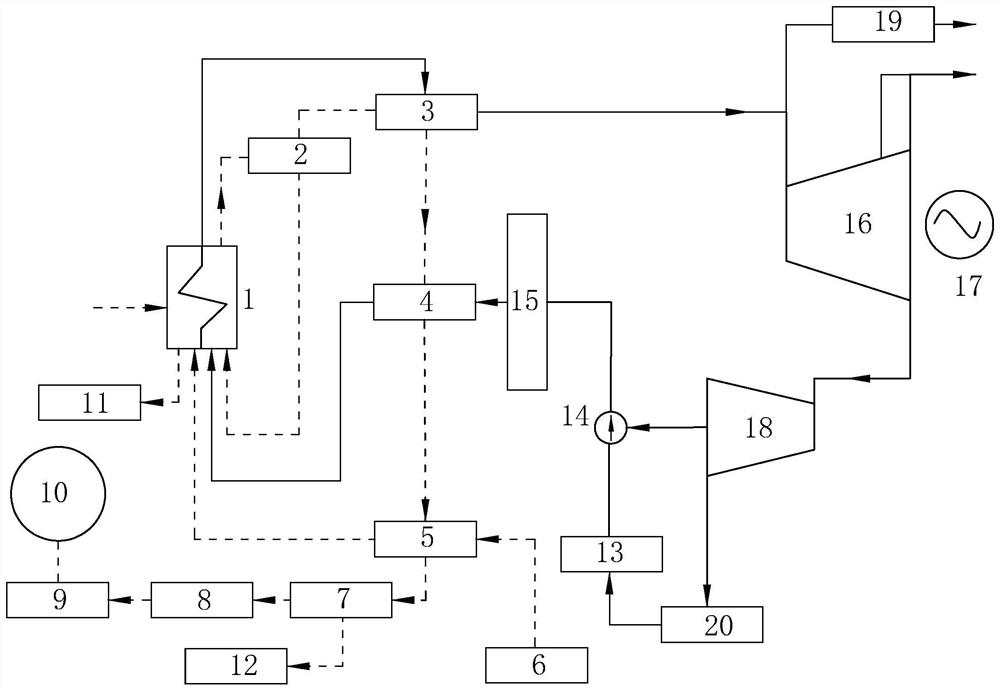

[0037] The following is attached Figure 1-4 The application is described in further detail.

[0038] refer to figure 1 , a cogeneration system under ultra-high temperature and ultra-high pressure parameters, including ultra-high temperature and ultra-high pressure circulating fluidized bed boiler 1, cyclone separator 2, superheater 3, economizer 4, air preheater 5, blower 6, Bag filter 7, induced draft fan 8, desulfurization tower 9, chimney 10, slag storage 11, ash storage 12, high-pressure deaerator 13, steam-driven feed water pump 14, high-pressure heater 15, back pressure steam turbine 16, generator 17 , Drag steam turbine 18, temperature and pressure reducer 19 and preheater 20. It should be noted that the above-mentioned mechanical devices are all clearly and comprehensively described in the related art, so this application will not repeat them again.

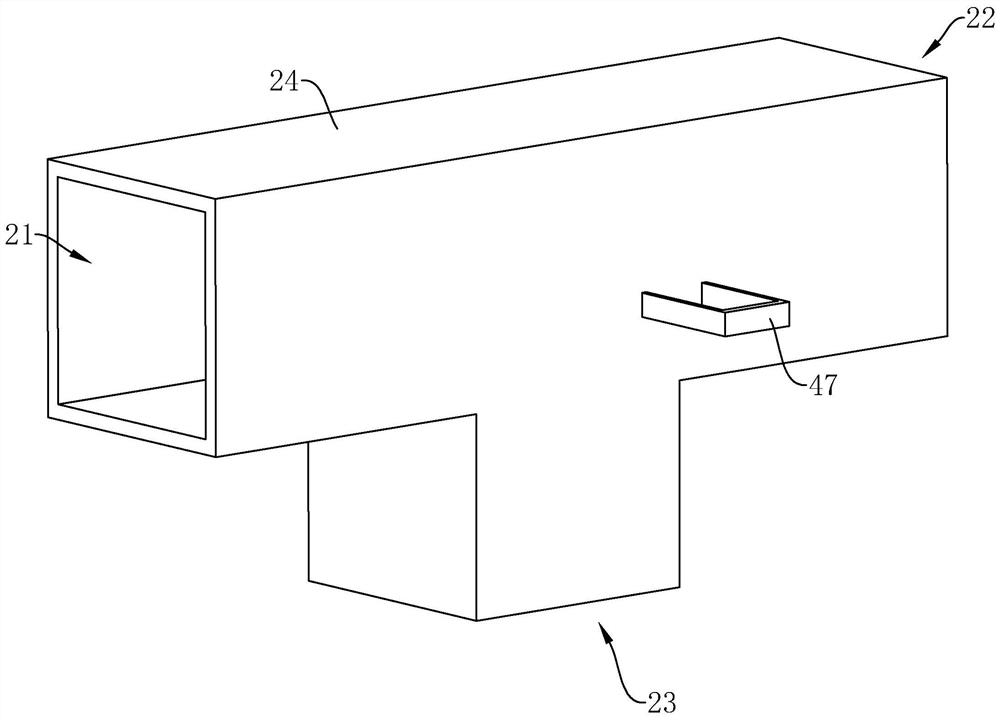

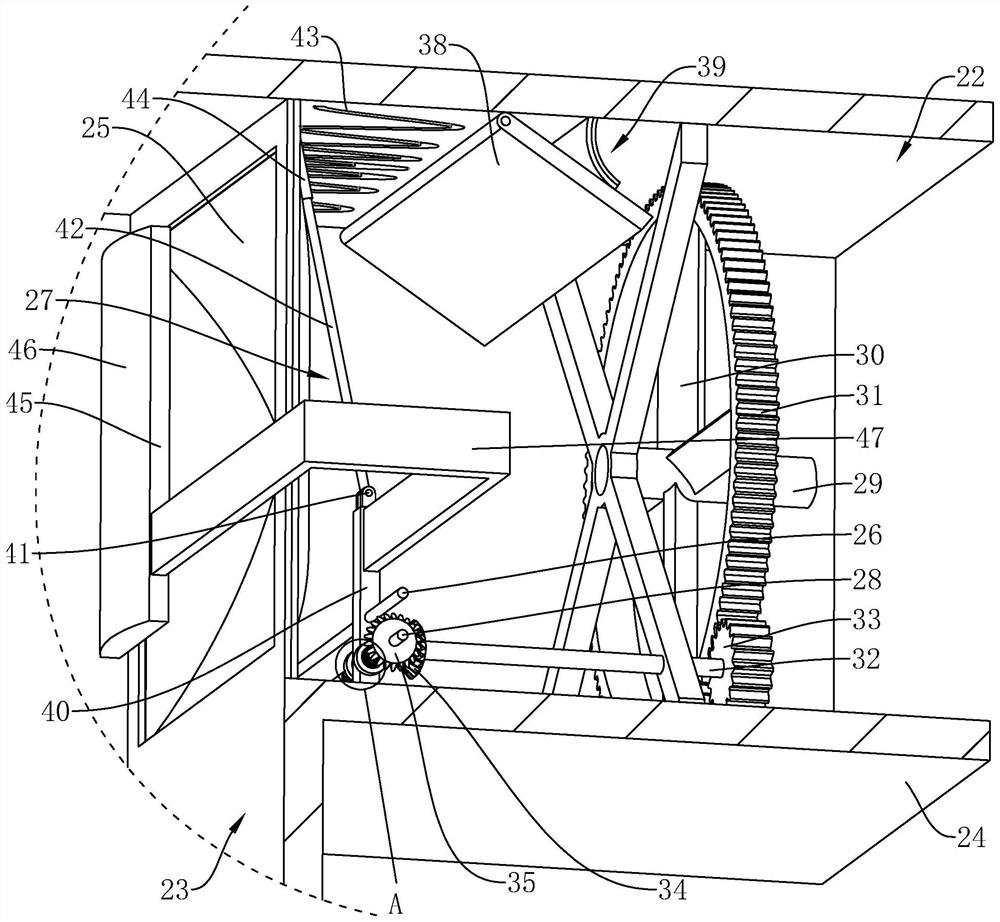

[0039] refer to figure 2 with image 3 , the bag filter 7 includes a dust removal box 24 with an air inlet 21, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com