Self-cooling chip and temperature measuring device and method thereof

A temperature measurement device and self-heating technology, applied in measurement devices, microstructure devices, optical devices, etc., can solve the problems of MEMS device failure, increased chip heat generation, unsuitability for MEMS systems, etc., and achieve accurate temperature measurement area. Increase heat dissipation efficiency and achieve the effect of self-heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention is further explained in connection with the accompanying drawings;

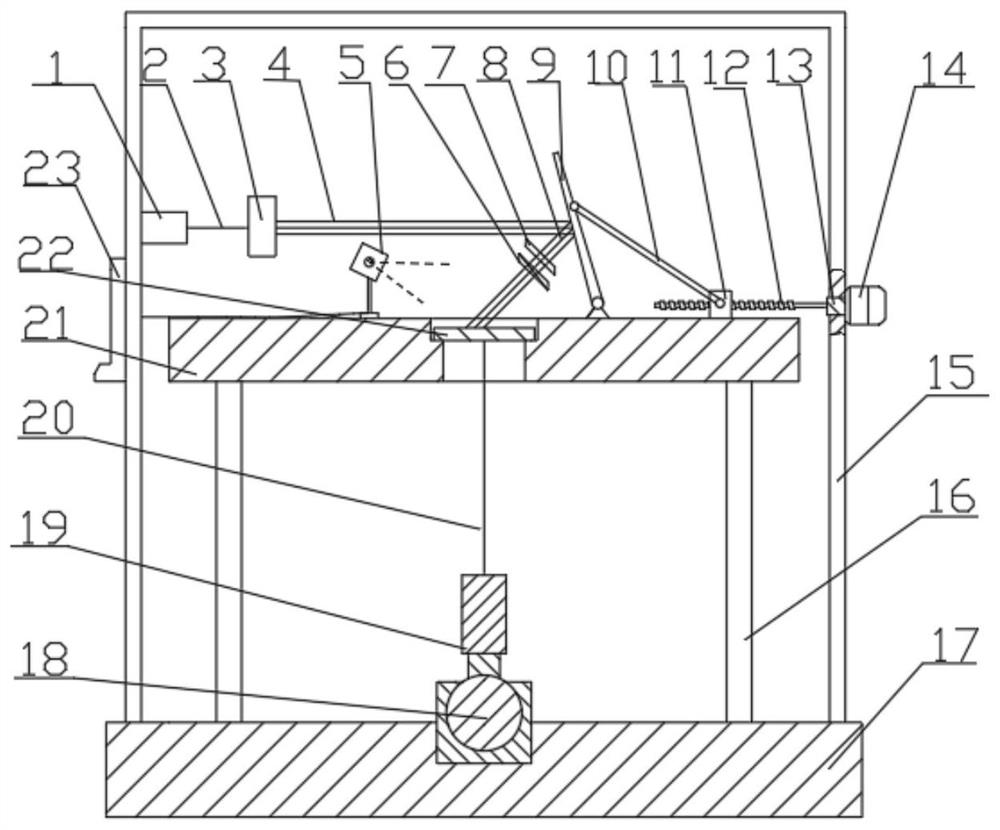

[0029] like figure 1 As shown, a chip temperature measuring device includes a measuring laser 1, a beam mirror 3, a CCD camera 5, a attenuation mirror 6, a filter 7, a wedge plate 9, a transmission mechanism, a coupling 13, a servo motor 14, a housing 15. Workbench, spherical hinge 18, computer 23 and heating laser 19. The transmission structure includes a link 10, a slider 11, and a ball screw 12, a table including a block 16, a platform base 17, and a platform upper surface 21. The platform base 17 is placed on the ground, and the outer casing 15 cover is on the platform base 17. The temperature measurement element is equally installed in the interior space of the outer casing, which can effectively block the interference of the external independent factor.

[0030] The measuring laser 1 is fixed to the outer casing 15; one end of the wedge plate 9 is fixed to the upper surface 21 of the pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap