Preparation method of high-purity hydrogen bromide

A hydrogen bromide, high-purity technology, applied in directions such as hydrogen bromide, bromine/hydrogen bromide, etc., can solve problems such as leakage, and achieve the effects of reducing easy explosion, high product stability, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

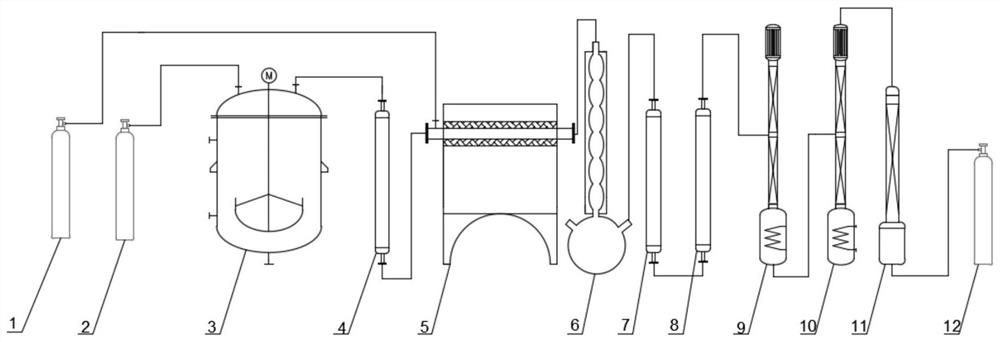

Method used

Image

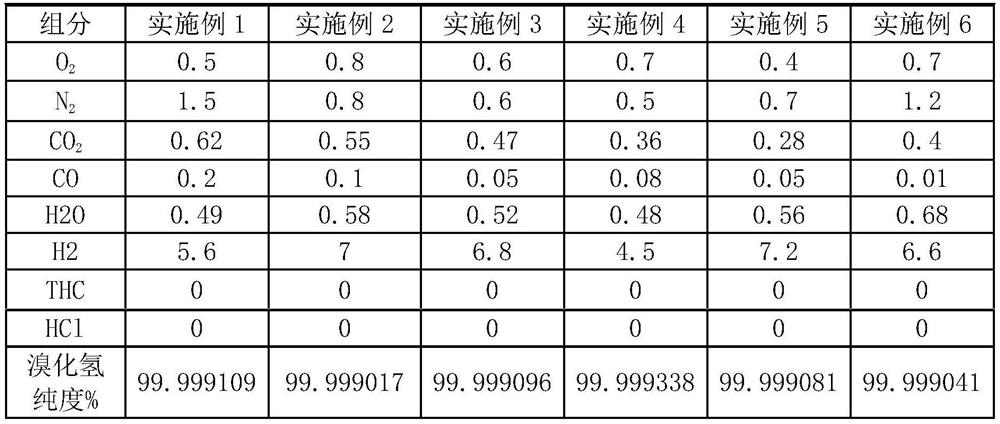

Examples

Embodiment 1

[0044] Step S1: prepare a 40% sodium bromide solution in an environment protected by nitrogen gas.

[0045] S2 step: purging all containers after cleaning and drying with nitrogen, under nitrogen protection atmosphere, add 2.5kg sodium bromide solution in the bromine generator, at this moment, under the condition of stirring, the control reactor temperature is 15 °C, the amount of chlorine gas introduced was 3L / min, and the reaction time was 1.5h.

[0046] Step S3: Slowly increase the temperature of the bromine generator, the temperature is controlled at 65° C., the pressure is 0.03 MPa, the bromine is evaporated, and the moisture in the bromine is removed through a drying tower.

[0047] Step S4: the bromine flow after drying is controlled at 1m 3 / h into a fixed bed preheated at 340°C and filled with catalyst, and the amount of hydrogen introduced at this time is 1.5m 3 / h to prepare crude hydrogen bromide.

[0048] Step S5: the crude hydrogen bromide is cooled by cooling...

Embodiment 2

[0051] Step S1: prepare a 35% sodium bromide solution in an environment protected by nitrogen gas.

[0052] S2 step: purging all the containers after cleaning and drying with nitrogen, under nitrogen protection atmosphere, add 2.5kg sodium bromide solution in the bromine generator, at this moment, under the condition of stirring, control the reactor temperature to be 25 ℃, the amount of chlorine gas introduced is 2.5L / min, and the reaction time is 2h.

[0053] Step S3: Slowly increase the temperature of the bromine generator, the temperature is controlled at 60° C., the pressure is 0.03 MPa, the bromine is evaporated, and the moisture in the bromine is removed through a drying tower.

[0054] Step S4: the bromine flow after drying is controlled at 1m 3 / h into a fixed bed preheated at 340°C and filled with catalyst, and the amount of hydrogen introduced at this time is 1.5m 3 / h to prepare crude hydrogen bromide.

[0055] Step S5: the crude hydrogen bromide is cooled by coo...

Embodiment 3

[0058] Step S1: prepare a 50% lithium bromide solution in an environment protected by nitrogen gas.

[0059] Step S2: purging all the containers after washing and drying with nitrogen, and adding 2.5 kg of lithium bromide solution to the bromine generator under nitrogen protection atmosphere, at this time, under the condition of stirring, the temperature of the reactor is controlled to be 20 ° C, The amount of chlorine gas introduced was 2.8L / min, and the reaction time was 3h.

[0060] Step S3: Slowly increase the temperature of the bromine generator, the temperature is controlled at 60° C., the pressure is 0.03 MPa, the bromine is evaporated, and the moisture in the bromine is removed through a drying tower.

[0061] Step S4: the bromine flow after drying is controlled at 1m 3 / h enters the fixed bed preheated at 360°C and filled with catalyst, and the amount of hydrogen introduced at this time is 2m 3 / h to prepare crude hydrogen bromide.

[0062] Step S5: the crude hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com