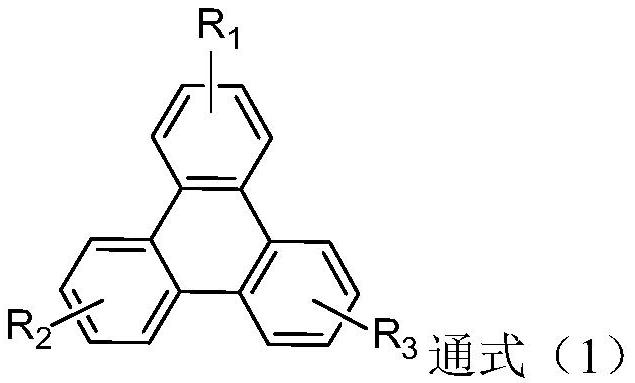

Triphenylene derivative, light-emitting element material and light-emitting element

A derivative, triphenylene technology, applied to triphenylene derivatives, can solve problems such as lack of materials, and achieve the effects of easy availability of raw materials, high-efficiency luminescence performance, and reduction of vibration energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

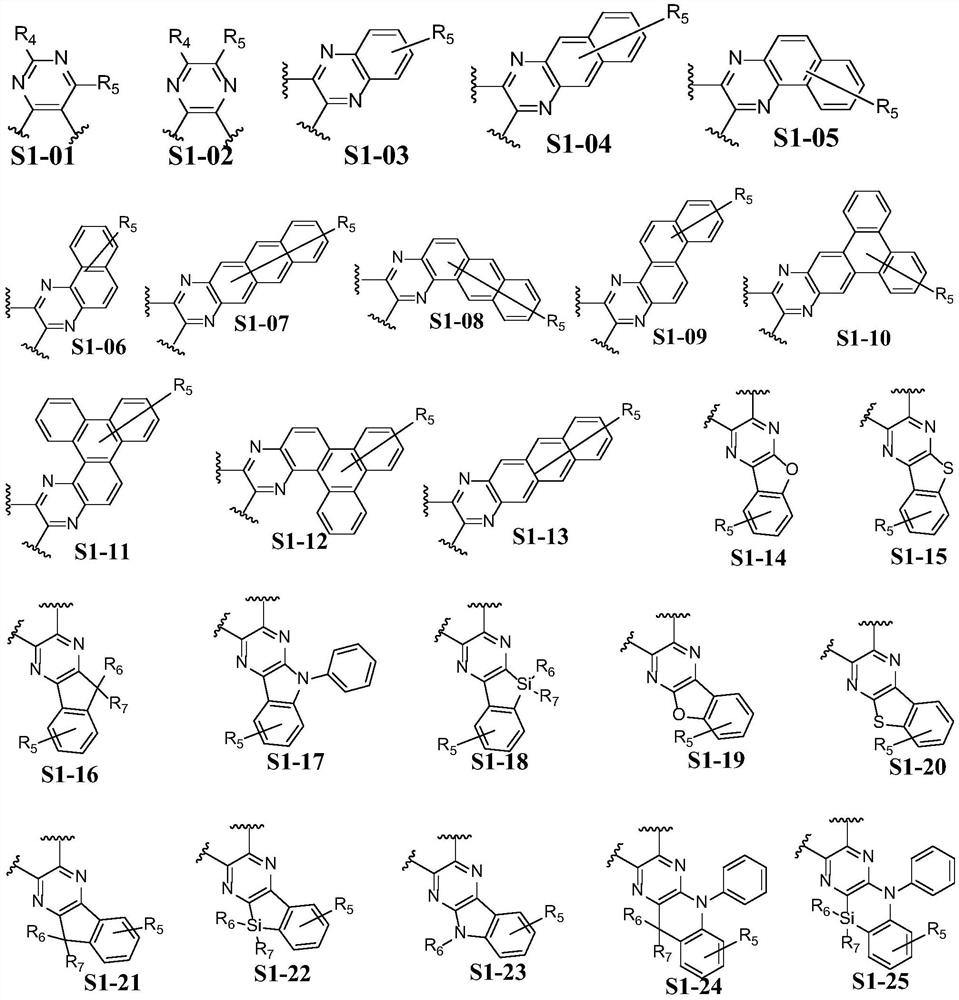

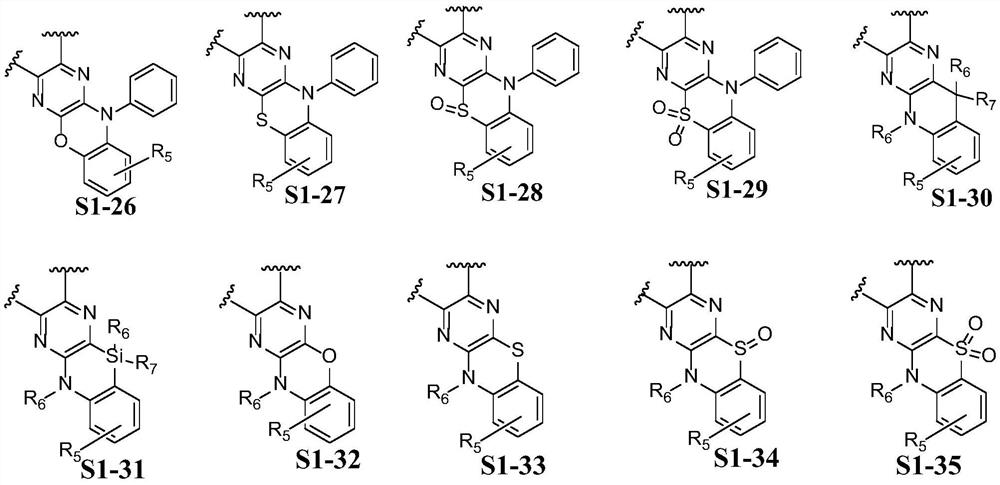

Method used

Image

Examples

Embodiment 1

[0067] Synthesis of compound 1

[0068]

[0069] Under an argon atmosphere, 50.5 grams (100 mmol) of N-(7,10-dibromoterphenyl-2-yl) benzamide and 12.5 grams (120 mmol) of 2-chloropyridine were added to the reaction flask, and 300 ml of methylene chloride was cooled to -78°C, then 31.0 g (110 mmol) of trifluoromethanesulfonic anhydride was added, and the reaction mixture was placed in an ice-water bath and heated to 0°C. 11 g (110 mmol) of benzonitrile was added. The reaction mixture was heated to 45°C and reacted for 6 hours, then cooled to room temperature and triethylamine was added to neutralize trifluoromethanesulfonate. The volatiles were removed under reduced pressure, and 51.9 g of 3,6-dibromo-11,13-diphenylphenanthroquinazoline were obtained by flash column chromatography (eluent: 10% ethyl acetate in hexane), Yield 88%, HPLC purity 99.6%.

[0070] 1 HNMR(DMSO): δ9.10(s, 1H), 8.93(s, 1H), 8.81(d, 1H), 8.35(m, 2H), 8.29(s, 1H), 8.12(s, 1H), 8.05 ~7.99(m, 3H), 7.8...

Embodiment 2

[0074] Synthesis of compound 20

[0075]

[0076] Under an argon atmosphere, 50.5 grams (100 mmol) of N-(7,10-dibromoterphenyl-2-yl) benzamide and 12.5 grams (120 mmol) of 2-chloropyridine were added to the reaction flask, and 300 ml of methylene chloride was cooled to -78°C, then 31.0 g (110 mmol) of trifluoromethanesulfonic anhydride was added, and the reaction mixture was placed in an ice-water bath and heated to 0°C. 11 g (110 mmol) of benzonitrile was added. The reaction mixture was heated to 45°C and reacted for 6 hours, then cooled to room temperature and triethylamine was added to neutralize trifluoromethanesulfonate. The volatiles were removed under reduced pressure, and 51.9 g of 3,6-dibromo-11,13-diphenylphenanthroquinazoline were obtained by flash column chromatography (eluent: 10% ethyl acetate in hexane), Yield 88%, HPLC purity 99.6%.

[0077] 1 HNMR(DMSO): δ9.10(s, 1H), 8.93(s, 1H), 8.81(d, 1H), 8.35(m, 2H), 8.29(s, 1H), 8.12(s, 1H), 8.05 ~7.99(m, 3H), 7....

Embodiment 3

[0082] Synthesis of Compound 28

[0083]

[0084] Under an argon atmosphere, add 46.0 grams (100 mmol) of N-(7-bromo-10-chlorobenzo-2-yl) benzamide and 12.5 grams (120 mmol) of 2-chloropyridine to 300 ml of dichloromethane in the reaction flask, and cool down to -78°C, then added 31.0 g (110 mmol) of trifluoromethanesulfonic anhydride, and placed the reaction mixture in an ice-water bath and heated to 0°C. Added 11 g (110 mmol) of benzonitrile. The reaction mixture was heated to 45°C and reacted for 6 hours, then cooled to room temperature and triethylamine was added to neutralize trifluoromethanesulfonate. The volatiles were removed under reduced pressure and flash column chromatography (eluent: 10% ethyl acetate in hexane) gave 46.3 g of 6-bromo-3-chloro-11,13-diphenylphenanthroquinazoline , yield 85%, HPLC purity 99.4%.

[0085] 1 HNMR(DMSO): δ9.10(s, 1H), 8.93(s, 1H), 8.81(d, 1H), 8.35(m, 2H), 8.29(s, 1H), 8.12(s, 1H), 8.05 ~7.99(m, 3H), 7.80(d, 2H), 7.65(t, 2H), 7....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com