Antibacterial suction nozzle, preparation method thereof, and electronic atomization device having the same

An antibacterial agent and fluoroorganic technology are applied in the field of an antibacterial suction nozzle, a preparation method thereof, and an electronic atomization device having the suction nozzle, which can solve the problems of reducing the mechanical properties of PCTG materials, increasing the material cost, and brittle and brittle finished products. , to achieve the effect of increasing the effective concentration, antibacterial and antiviral activity, and improving antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

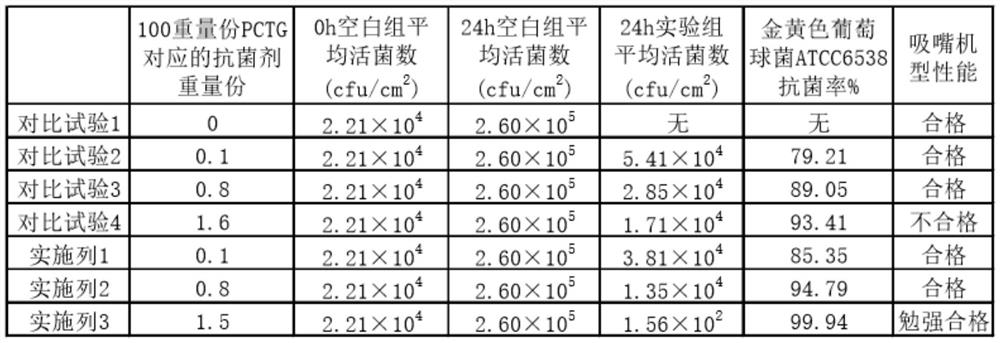

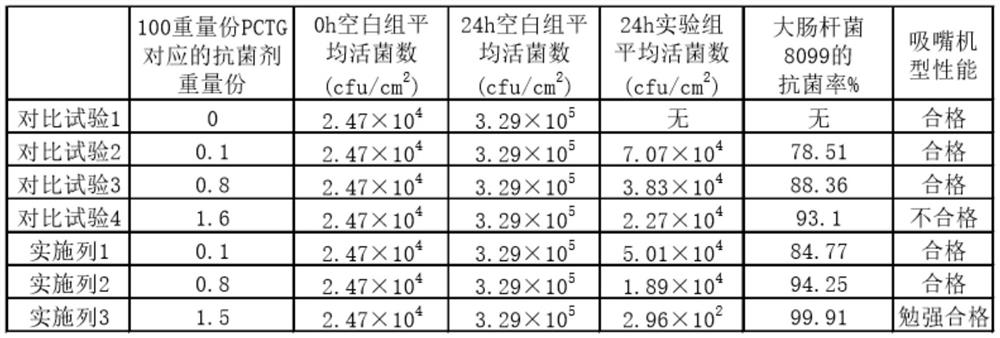

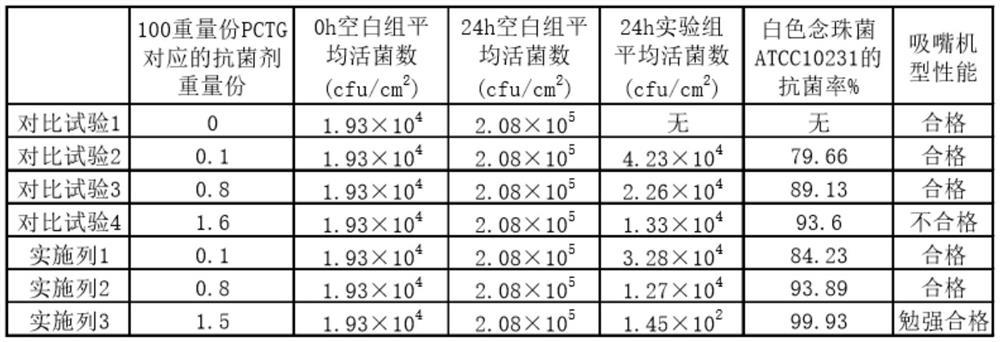

Embodiment 1

[0038]Get 100 grams of the above-mentioned commercially available zirconium phosphate as the nano-silver ion antibacterial agent powder (containing 1 gram of silver ion), be uniformly dispersed in 1000 milliliters of dehydrated alcohol under mechanical stirring to form a suspension, then add 4.34 grams of perfluorinated Octyltrimethoxysilane is used as an oleophobic modifier in the above suspension, and the molar ratio of the oleophobic modifier to the silver ions in the antibacterial agent powder is 1:1. After immersion for 12 hours, it is separated by a rotary evaporator. absolute ethanol to obtain the surface-modified oleophobic nano-silver ion antibacterial agent. Take the oleophobic nano-silver ion antibacterial agent, dried PCTG pellets, and brown toner, mix them evenly according to the mass ratio of 0.1:100:0.01, and then feed them into the injection molding machine. With the help of nozzle mold and conventional injection molding process, Squeeze out several tan nozzle ...

Embodiment 2

[0040] Take 100 grams of the above-mentioned self-made zirconium phosphate as the carrier nano-silver ion antibacterial agent powder (containing 1 gram of silver ion), and evenly disperse it in 1000 milliliters of isopropanol to form a suspension under mechanical stirring, then add 4.80 grams of perfluorodecane Acrylate is used as an oleophobic modifier in the above suspension, and the molar ratio of the oleophobic modifier to the silver ion in the antibacterial agent powder is 1:1. After 12 hours of immersion, use a rotary evaporator to separate absolute ethanol , to obtain surface-modified oleophobic nano-silver ion antibacterial agent. Take the oleophobic nano-silver ion antibacterial agent, dried PCTG pellets, and gray toner, mix them evenly according to the mass ratio of 0.8:100:0.05, and then feed them into the injection molding machine. With the help of nozzle mold and conventional injection molding process, Extrude several colorless nozzle samples.

Embodiment 3

[0042] Get 100 grams of the above-mentioned commercially available calcium carbonate as the nano-silver ion antibacterial agent powder (containing 1 gram of silver ion) of the carrier, and evenly disperse it in 1000 milliliters of acetone to form a suspension under mechanical stirring, then add 5.38 grams of perfluorinated dodeca Alkyl trichlorosilane is used as an oleophobic modifier in the above suspension. The molar ratio of the oleophobic modifier to the silver ion in the antibacterial agent powder is 1:1. After 12 hours of immersion, the acetone is separated by a rotary evaporator. , to obtain surface-modified oleophobic nano-silver ion antibacterial agent. Take the oleophobic nano-silver ion antibacterial agent, dried PCTG pellets, and pink toner, mix them evenly according to the mass ratio of 1.5:100:0.1, and then feed them into the injection molding machine. With the help of nozzle mold and conventional injection molding process, Squeeze out several gray nozzle samples...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com