High-weather-resistance polysiloxane type noctilucent coating and preparation method thereof

A polysiloxane-type, luminous coating technology, applied in luminescent coatings, fireproof coatings, coatings, etc., can solve the problems of poor weather resistance and low operating temperature of luminous paint films, and achieve the effect of maintaining luminous brightness and reducing the degree of aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

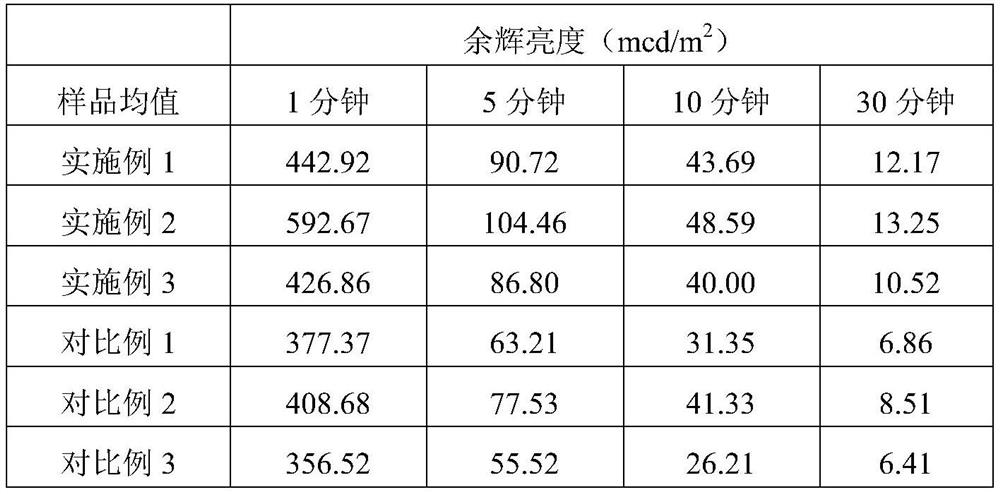

Embodiment 1

[0019] 100g of methyl vinyl silicone oil with a vinyl content of 1.2wt% (viscosity of 30000MPa·S), 10g of methyl hydrogen silicone oil with a hydrogen content of 0.3wt% (viscosity of 500MPa·S), 0.01g of acetylene cyclohexane Dissolve alcohol in 30g cyclohexane, mix well, then add 30g methyl MQ resin, 5g vinyl MQ resin with a vinyl content of 3.0wt%, 5g luminous powder BL-2A, and then add 0.05g 5000ppm platinum- Vinyl siloxane solution of vinyl siloxane complex, 0.05g AIBN, after mixing evenly, put into planetary mixer to remove solvent cyclohexane and air bubbles in a vacuum, and obtain viscous fluid polysiloxane with uniform dispersion of luminous powder Type luminous paint (luminous powder content 3.33wt%).

Embodiment 2

[0021] 100g of methyl vinyl silicone oil with a vinyl content of 1.44wt% (viscosity of 15000MPa·S), 20g of methyl hydrogen silicone oil with a hydrogen content of 0.36wt% (viscosity of 250MPa·S), 0.06g of acetylene cyclohexane Dissolve alcohol in 40g cyclohexane, mix well, then add 60g methyl MQ resin, 10g vinyl MQ resin with a vinyl content of 1.0wt%, 15g luminous powder GL-4A, and then add 0.1g 5000ppm platinum- Vinyl siloxane solution of vinyl siloxane complex, 0.1g AIBN, after mixing evenly, put into a planetary power mixer to remove solvent cyclohexane and air bubbles in a vacuum, and obtain viscous fluid polysiloxane with uniform dispersion of luminous powder Type luminous paint (luminous powder content 7.32wt%).

Embodiment 3

[0023] 100g of methyl vinyl silicone oil with a vinyl content of 2.0wt% (viscosity of 3000MPa·S), 15g of methyl hydrogen silicone oil with a hydrogen content of 1.0wt% (viscosity of 50MPa·S), 0.04g of acetylene cyclohexane Dissolve alcohol in 35g of petroleum ether, mix well, then add 50g of methyl MQ resin, 7g of vinyl MQ resin with a vinyl content of 2.0wt%, 10g of luminous powder GL-8C, and then add 0.08g of 5000ppm platinum-ethylene Vinyl siloxane solution of base siloxane complex, 0.08g AIBN, after mixing evenly, put into planetary mixer to remove solvent cyclohexane and air bubbles in a vacuum, and obtain viscous fluid polysiloxane type with luminous powder evenly dispersed Luminous paint (luminous powder content 5.49wt%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com