Broadband short-wave infrared luminescent material, preparation method and application thereof

An infrared luminescence, broadband short-wave technology, applied in luminescent materials, chemical instruments and methods, semiconductor devices, etc., can solve the problems of short emission wavelength, small emission half-peak width, etc., and achieves simple preparation method, low equipment requirements, and crystalline performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In the second aspect of the present invention, the present invention provides a method for preparing a broadband short-wave infrared luminescent material, comprising: mixing materials, first evaporating to dryness at a low temperature, and then sintering at a high temperature to obtain a broadband short-wave infrared luminescent material. Further, the materials include Li-containing compounds, Mg-containing compounds, P-containing compounds, Cr-containing compounds, Ni-containing compounds, Na-containing compounds, K-containing compounds, Ca-containing compounds, Sr-containing compounds, and Ba-containing compounds.

[0040] In one or more embodiments of the present invention, the preparation method specifically includes: mixing and dissolving the materials in distilled water, fully stirring, and placing them in an oven at 80-100° C. to evaporate to dryness, grinding the product obtained at low temperature again, and raising the temperature. High temperature sintering is...

Embodiment 1

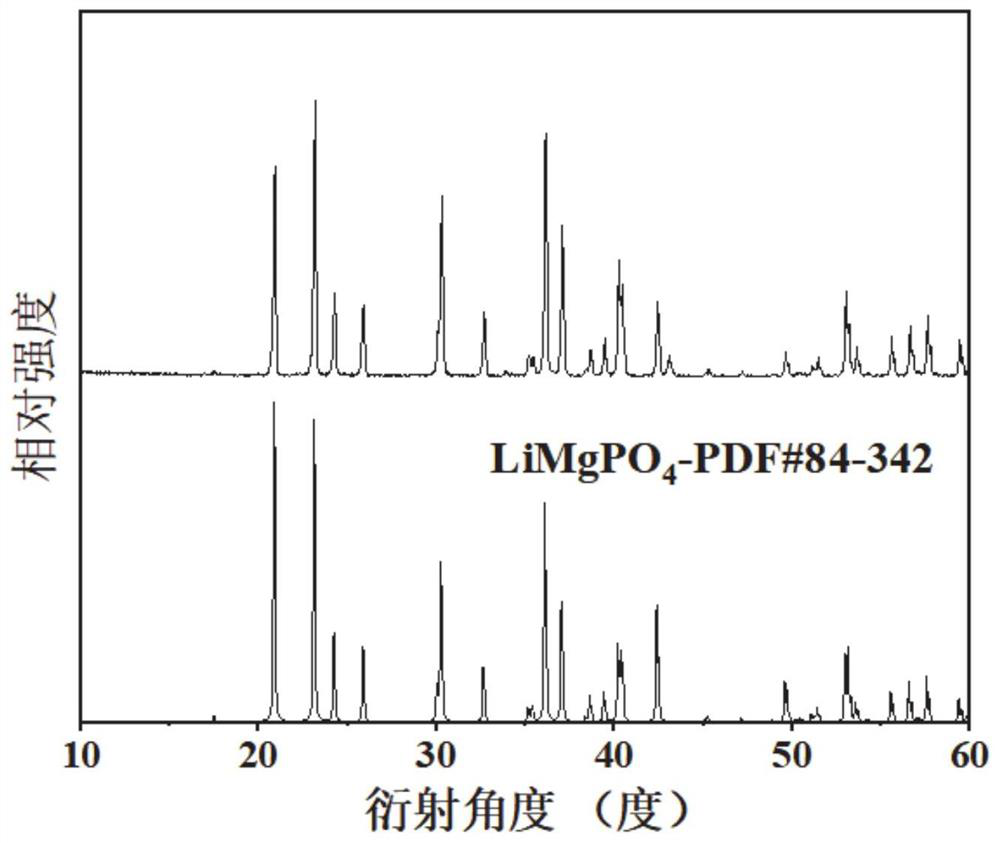

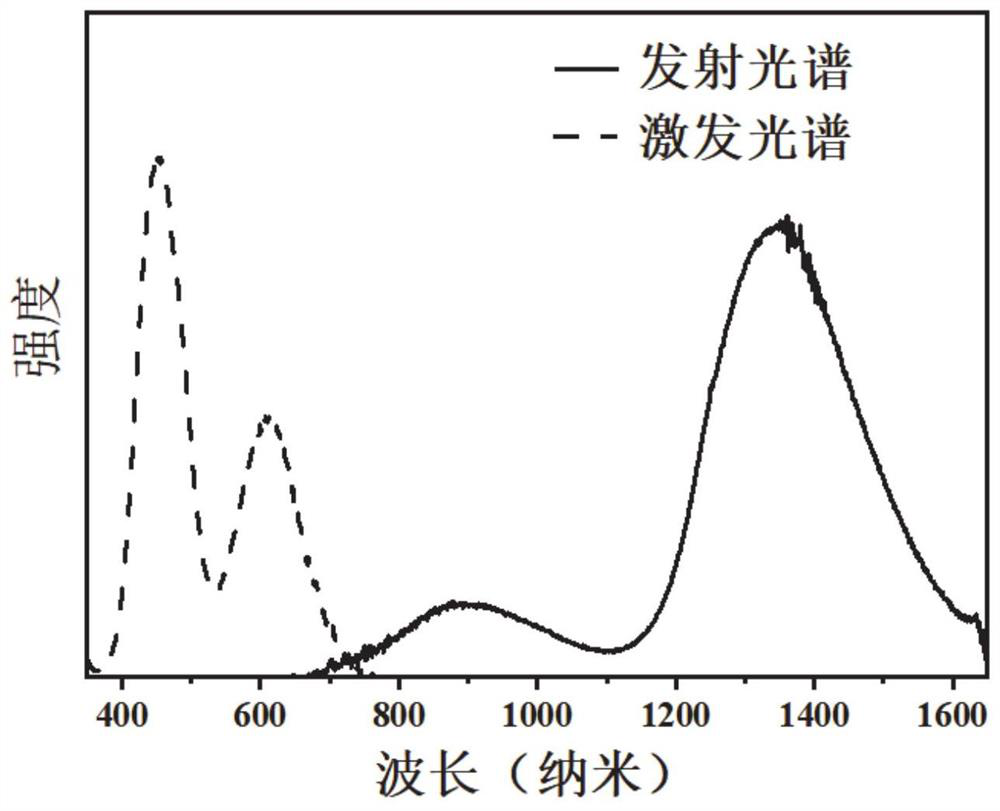

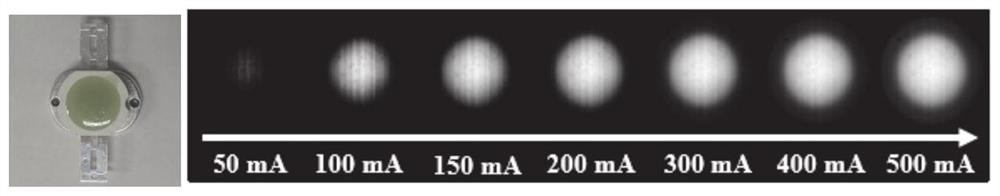

[0063] According to the following composition: Broadband short-wave infrared light-emitting material LiMgPO 4 : 0.5%Cr 3+ ,0.001%Ni 2+ , with LiMgPO 4 As the host, the doping ions are Cr ions and Ni ions, wherein the doping amount of Cr is 0.5 mol%, and the doping amount of Ni is 0.001 mol%. Accurately weigh lithium nitrate (LiNO 3 ) 0.2108g, magnesium nitrate (Mg(NO 3 ) 2 ·6H 2 O) 0.7766g, ammonium dihydrogen phosphate (NH 4 H 2 PO 4 )0.3287g, chromium nitrate (Cr(NO 3 ) 3 ·9H 2 O) 0.0057g, nickel nitrate (Ni(NO) with a concentration of 0.01mol / L 3 ) 2 ) aqueous solution 2.86 μL. The above raw materials were dissolved in a beaker and stirred for about 1 hour to fully mix the raw materials and then moved to an evaporating dish, and dried in an oven at 100° C. for 8 hours. After regrinding, the dried powder was sintered at a high temperature of 1000 °C for 10 hours to obtain LiMgPO excited by blue light. 4 : 0.5%Cr 3+ ,0.001%Ni 2+ Broadband short-wave infrared...

Embodiment 2

[0070] According to the following composition: Broadband short-wave infrared light-emitting material Li 0.8 Na 0.2 MgPO 4 : 0.5%Cr 3+ ,0.001%Ni 2+ , with Li 0.8 Na 0.2 MgPO 4 As the host, the doping ions are Cr ions and Ni ions, wherein the doping amount of Cr is 0.5 mol%, and the doping amount of Ni is 0.001 mol%. Accurately weigh lithium nitrate (LiNO 3 ) 0.1686g, sodium nitrate (NaNO 3 ) 0.0520g, magnesium nitrate (Mg(NO 3 ) 2 ·6H 2 O) 0.7766g, ammonium dihydrogen phosphate (NH 4 H 2 PO 4 )0.3287g, chromium nitrate (Cr(NO 3 ) 3 ·9H 2 O) 0.0057g, nickel nitrate (Ni(NO) with a concentration of 0.01mol / L 3 ) 2 ) aqueous solution 2.86 μL. The above raw materials were dissolved in a beaker and stirred for about 1 hour to fully mix the raw materials and then moved to an evaporating dish, and dried in an oven at 100° C. for 8 hours. After regrinding, the dried powder was sintered at a high temperature of 1000 °C for 10 hours to obtain Li excited by blue light. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminescence peak wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com