Surface wear-resistant layer of spiral shaft for electronic glass and processing method

A processing method and screw shaft technology, which are applied in metal material coating process, coating, melting spray plating, etc., can solve the problems of glass product quality influence, uneven surface quality, uneven unevenness, and avoid local uneven heating. , The effect of stable crystal structure and prolonged service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

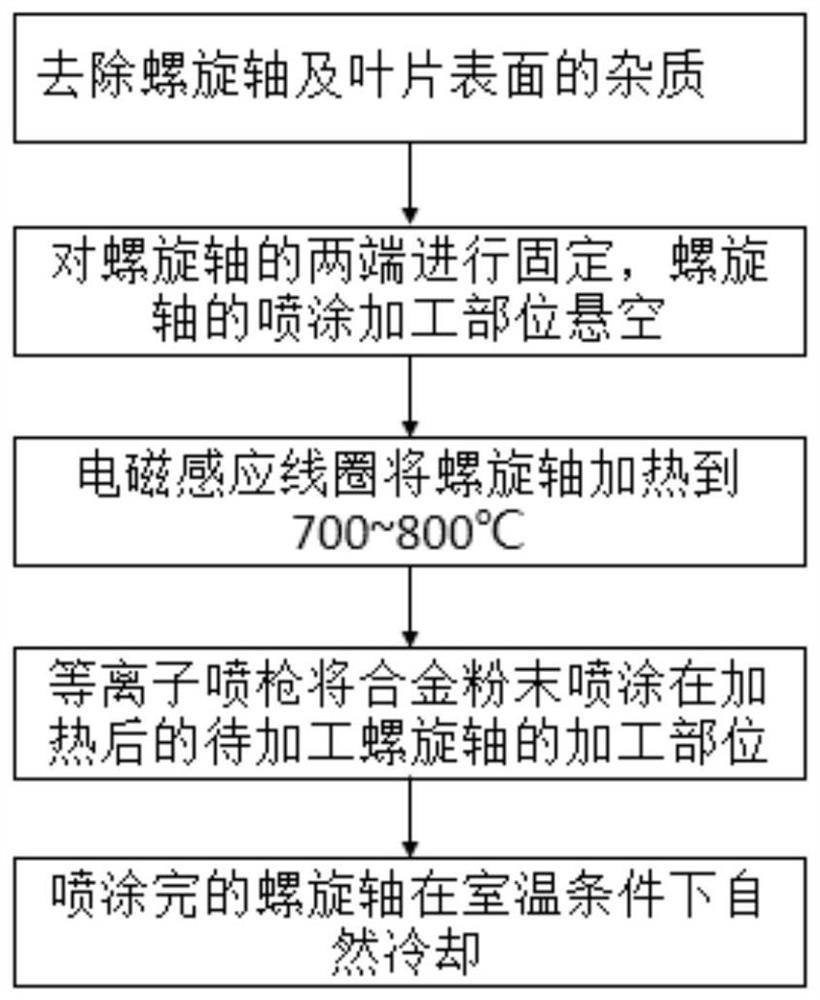

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0027] The purpose of the present invention is to provide a process method and application of plasma spraying on the surface of a spiral shaft for electronic glass. The plasma sprayed WC (tungsten carbide) wear-resistant layer provided by the present invention is suitable for electronic glass kiln feeders. The treatment of the wear-resistant layer on the surface of the screw shaft. The tungsten carbide wear-resistant layer has excellent wear resistance and high material maturity.

[0028] Plasma spraying is another coating process. The ion arc is a compressed arc with a thin arc column, high current density, high gas ionization degree, high temperature, energy concentration, and good arc stability. The working gas passes between the cathode and the nozzle. The electric arc is heated, causing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com