Complex-phase reaction sintering silicon carbide ceramic pump and manufacturing method thereof

A technology for sintering silicon carbide and silicon carbide ceramics, which is used in ceramic molding machines, pumps, pump components, etc., can solve the problems of high open porosity, limited application range, product performance impact, etc., to improve bulk density and reduce apparent pores. rate, good integration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for manufacturing a multiphase reaction sintered silicon carbide ceramic pump, comprising the following steps:

[0035] S1, prepare the pouring material, cast it into the assembled mold, release the molded green body, dry and repair the green body, burn the dried green body to prepare the silicon nitride bonded silicon carbide ceramic structural part b, Carrying out organic carburizing and curing in the pores of the silicon nitride bonded silicon carbide ceramic structure b;

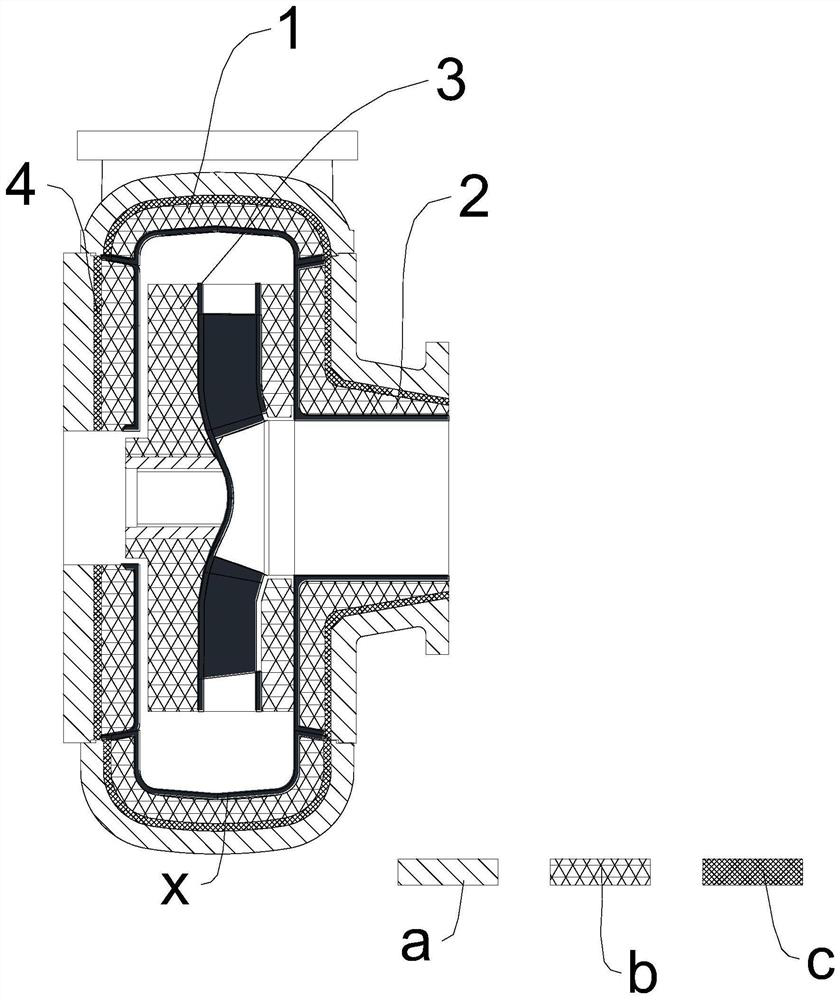

[0036] S2, the reaction sintered silicon carbide pouring or grouting molding cavity is formed by combining organic carburized silicon nitride and silicon carbide ceramic structural part b with the forming inner mold and gypsum outer mold, such as figure 1 The molding cavity shown is located on the inner wall of the pump casing 1, forming a layer of reaction sintered silicon carbide ceramic layer;

[0037]S3, pouring or grouting the reaction sintered silicon carbide slurry into the moldin...

Embodiment 2

[0045] A method for manufacturing a multiphase reaction sintered silicon carbide ceramic pump, comprising the following steps:

[0046] S1, prepare the pouring material, cast it into the assembled mold, demould, dry and trim the formed green body, and burn the dried green body to prepare silicon oxide bonded silicon carbide ceramic structural part b. Organic carburizing and curing are carried out in the pores of silicon oxide combined with silicon carbide ceramic structure b;

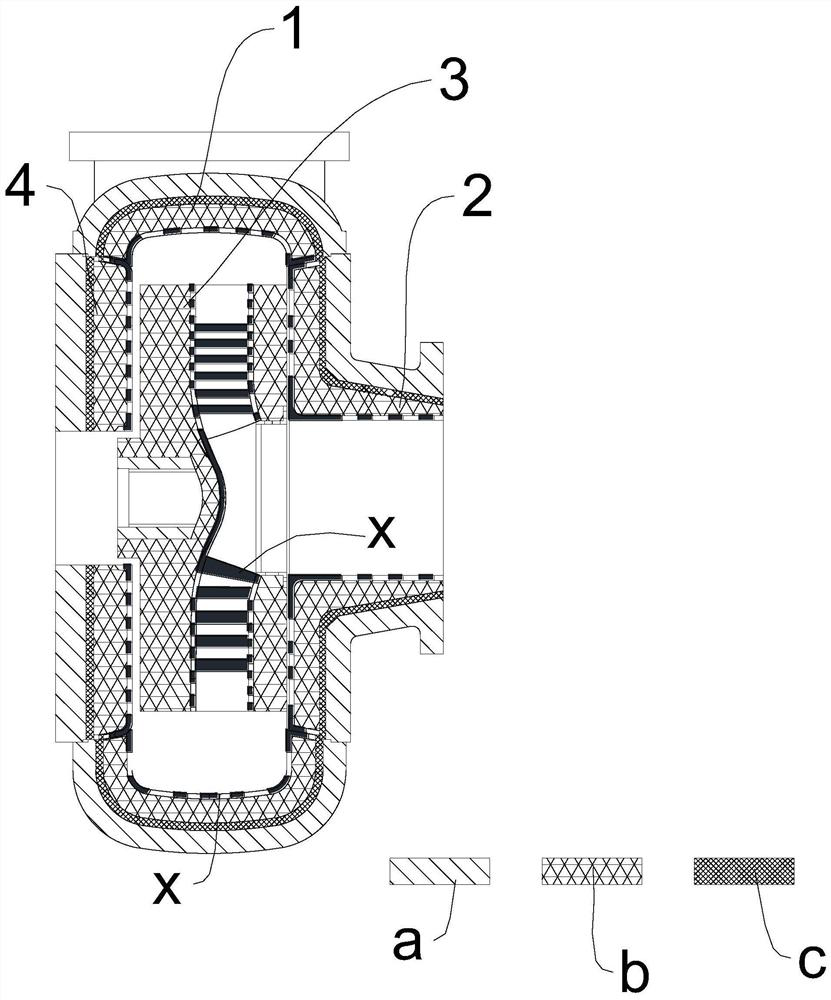

[0047] S2, the reaction sintered silicon carbide pouring or grouting molding cavity is formed by combining the organic carburized silicon oxide bonded silicon carbide ceramic structure b with the forming inner mold and the gypsum outer mold, such as figure 2 As shown, the reaction sintered silicon carbide is dispersed on the ceramic structure b;

[0048] S3, pouring or grouting the reaction sintered silicon carbide slurry into the molding cavity, after the molding is completed, let it stand for a peri...

Embodiment 3

[0056] A method for manufacturing a multiphase reaction sintered silicon carbide ceramic pump, comprising the following steps:

[0057] S1, prepare the pouring material, cast it into the assembled mold, demould, dry and trim the formed green body, and sinter the dried green body to prepare pressureless sintered silicon carbide and silicon nitride bonded carbide The ceramic structural part b made of silicon composite is organically carburized and solidified in the pores of the pressureless sintered silicon carbide ceramic structural part b;

[0058] S2, the ceramic structural part b made of organic carburized pressureless sintered silicon carbide and silicon nitride combined with silicon carbide, forming a reaction sintered silicon carbide casting or grouting molding cavity with a forming inner mold and a gypsum outer mold; pressureless The ceramic structural part b composed of sintered silicon carbide and silicon nitride combined with silicon carbide should be understood as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com