Multi-core optical fiber for different application scenes and preparation method

A multi-core fiber, application scenario technology, applied in the direction of multi-core fiber, multi-layer core/clad fiber, clad fiber, etc., can solve the problems of unmentioned fiber bending performance, fiber stress distribution, etc., to avoid energy The effect of leakage, high production efficiency and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method of preparing a multi-core fiber for different application scenarios, including the following steps:

[0032] The core and cladding are prepared, and the cladding is perforated, and then the plurality of cores are inserted into a plurality of wells of the cladding, and a core is inserted into a hole, and the wire drawing is performed to obtain the desired multi-core fiber.

[0033] The packet layer is first prepared from the VAD method (not limited to this process), and the punch is performed by high-precision punching equipment, the pore size is 10 ~ 30mm, the pore distance is 20 ~ 60mm, and the cladding The diameter is 50 ~ 120mm.

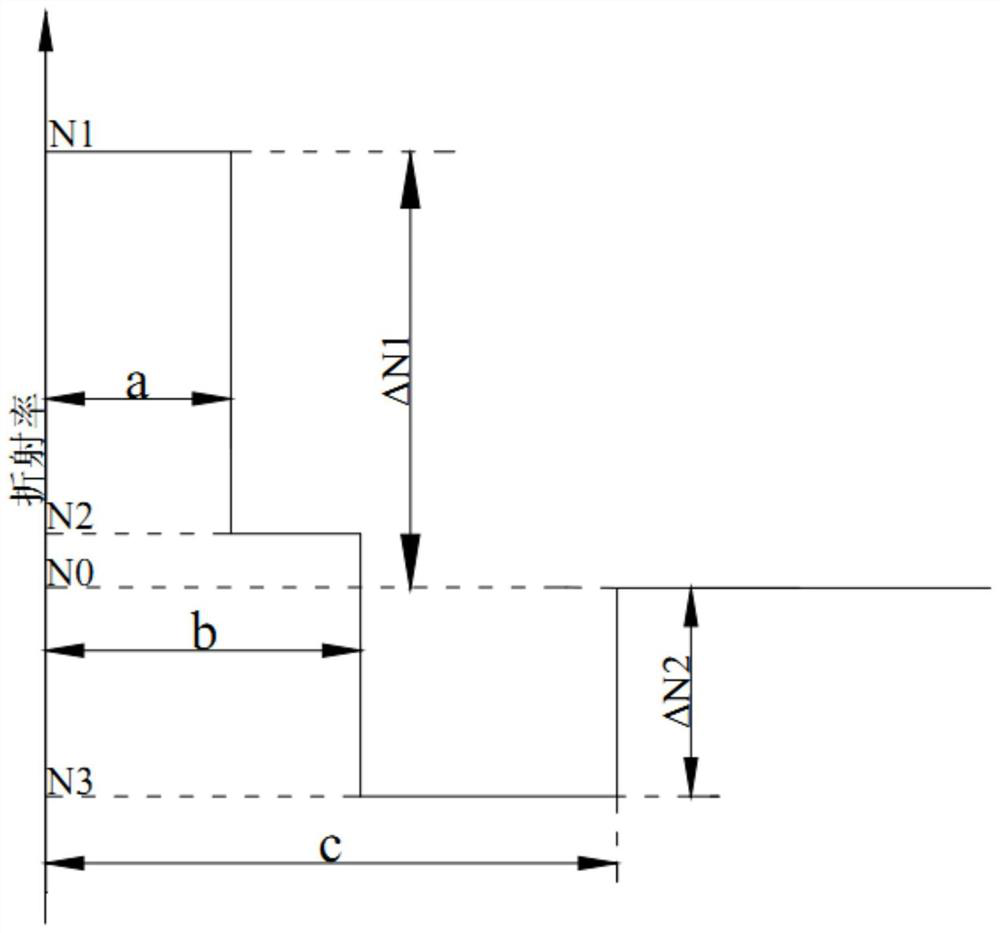

[0034] The bristle retaining core layer 1 radius A is 3.0 to 4.5 μm, the inner cladding layer 2 and the core layer 1 radius ratio B / A is 2.0 to 3.0, and the lower casing layer 3 and the core layer 1 radius ratio C / A is 3.0 to 4.0.

[0035] The spacing between adjacent two cores is 20 to 50 μm, the number of cores, and the adjacent ...

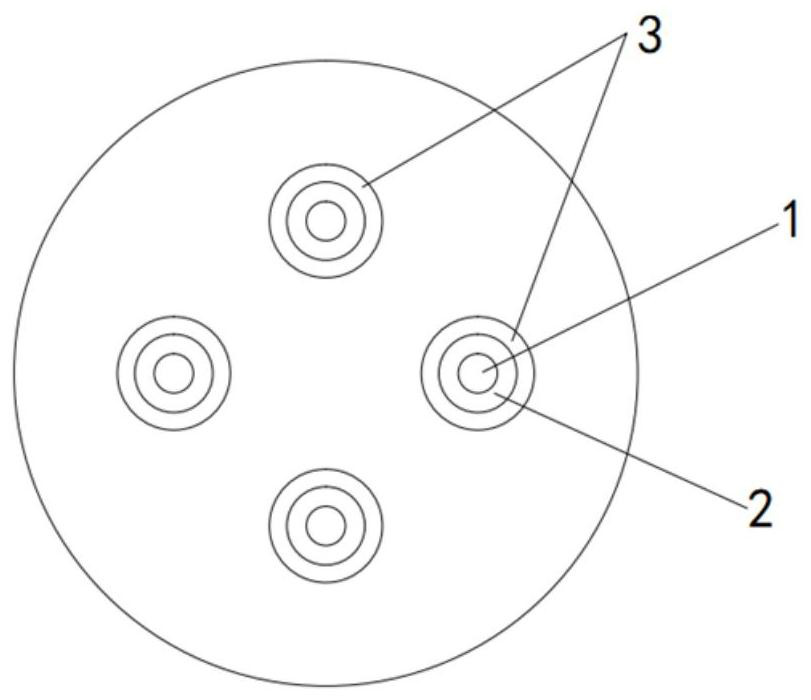

Embodiment 1

[0038] like Figure 1-2 As shown, a multi-core optical fiber for different application scenarios, an outer diameter of 125 μm, a four-core fiber composed of four cores and a cladding coated thereof, each core includes internally The core layer 1 (a radius is a), the inner clad layer 2 (B) and the lower cladding layer 3 (a radius C), the cladding of the width of the two-core fiber end surface structure of the adjacent core spacing of 40 μm It is made of high-precision hits, and the four cores are inserted into the four holes of the cladding, and then the wire draws the desired multi-core fiber.

[0039] After the bridler, the fiber 1550 nm attenuated ≤0.20, 1550 macro 1 lap (R = 10 mm) does not exceed 0.02 dB, reaching G.657.b3 standard.

[0040] After the brigadier, the core of the two cores of the fiber is not exceeding -50 dB.

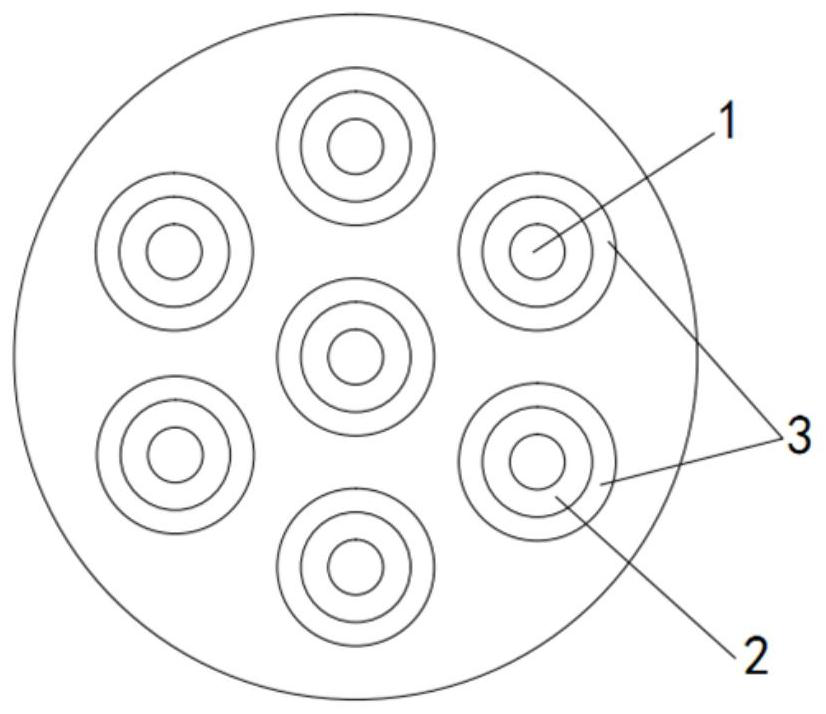

Embodiment 2

[0042] like figure 1 with 3 As shown, a multi-core optical fiber for different application scenes, an outer diameter of 125 μm, a seven-core fiber composed of a seven core and a cladding coated thereof, each of which includes internal and external sequential The core layer 1 (a radius is a), the inner clad layer 2 (B) and the lower clavoration 3 (a radius C), the cladding is a seven-core optical fiber end face structure by the pure silicon core rod to 30 μm. The high-precision hit seven well is made, and the seven cores are inserted into the seven holes of the lower cladding layer 3, and then the bridal obtains the desired multi-core fiber.

[0043] After the bridler, the fiber 1550 nm attenuated ≤0.20, 1550 macro 1 lap (R = 10 mm) does not exceed 0.02 dB, reaching G.657.b3 standard.

[0044] After the brigadier, the core of the two cores of the fiber is not exceeding -50 dB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com