Sealing slurry for prefabricated building and its preparation and use method

A technology for prefabrication and construction, applied in clay preparation devices, chemical instruments and methods, cement mixing devices, etc., can solve problems such as energy waste and environmental pollution, achieve short setting time, wide applicable temperature range, and reduce mixing The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

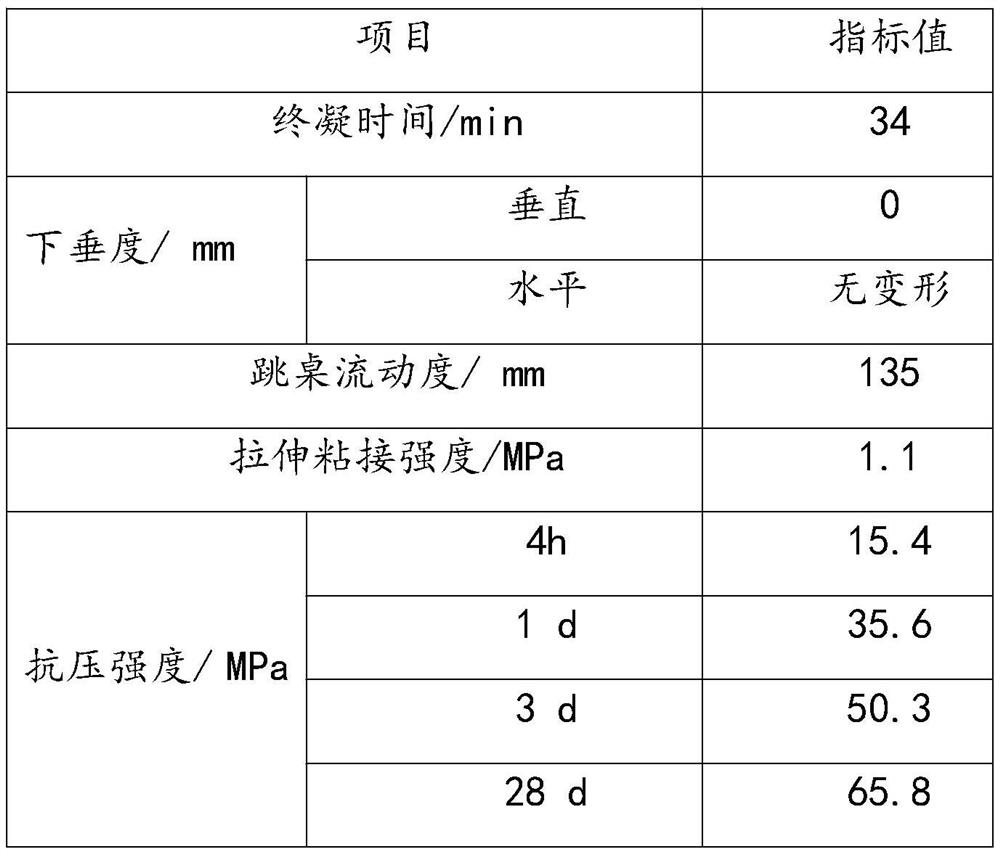

Embodiment 1

[0057] The prefabricated building sealing slurry is composed of A component and B component in a mass ratio of 8:2, wherein the A component is composed of: 38 parts of fast-setting and fast-hardening high belite sulfoaluminate cement, Portland cement 14 parts, 0.9 part of hydration regulator, 4 parts of ultra-fine fly ash, 0.3 part of UEA expansion agent, 49 parts of fine aggregate, 0.25 part of lignosulfonate water reducing agent, 0.1 part of silicone defoamer, hydroxyl 0.02 part of propyl methylcellulose, 0.02 part of redispersible latex powder, the composition of component B is: 46 parts of ultra-high strength sulfoaluminate cement, 7 parts of anhydrite, 3 parts of calcium aluminate amorphous phase, ultra-fine 4 parts of fly ash, 46 parts of fine aggregate, 0.1 part of lithium carbonate, 0.2 part of boric acid, 0.3 part of lignosulfonate water reducing agent, 0.1 part of silicone defoamer, 0.02 part of hydroxypropyl methylcellulose, 0.02 part of redispersible latex powder, ...

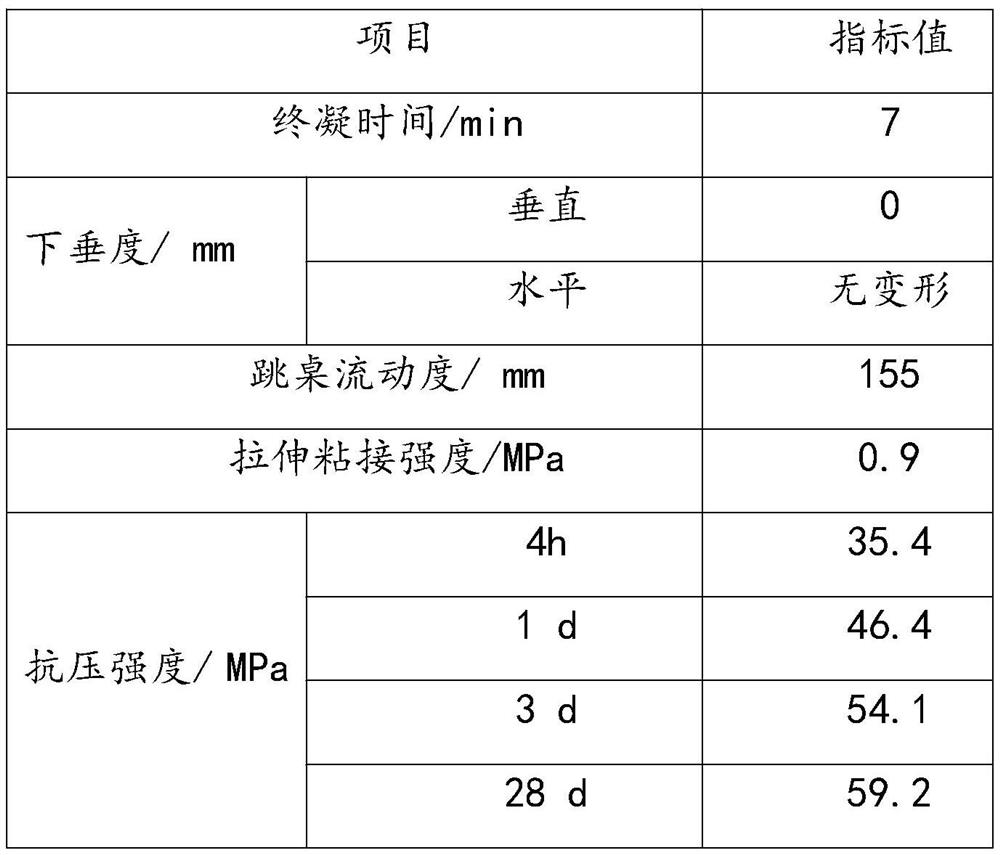

Embodiment 2

[0060] The prefabricated building sealing slurry is composed of the A component and the B component in a mass ratio of 2:8, wherein the A component is composed of: 38 parts of fast-setting and fast-hardening high Belite sulfoaluminate cement, Portland cement 14 parts, 0.9 part of hydration regulator, 4 parts of ultra-fine fly ash, 0.3 part of UEA expansion agent, 49 parts of fine aggregate, 0.25 part of lignosulfonate water reducing agent, 0.1 part of silicone defoamer, hydroxyl 0.02 part of propyl methylcellulose, 0.02 part of redispersible latex powder, the composition of component B is: 46 parts of ultra-high strength sulfoaluminate cement, 7 parts of anhydrite, 3 parts of calcium aluminate amorphous phase, ultra-fine 4 parts of fly ash, 46 parts of fine aggregate, 0.1 part of lithium carbonate, 0.2 part of boric acid, 0.3 part of lignosulfonate water reducing agent, 0.1 part of silicone defoamer, 0.02 part of hydroxypropyl methylcellulose, 0.02 part of redispersible latex ...

Embodiment 3

[0063] The prefabricated building sealing slurry is composed of A component and B component in a mass ratio of 7:3, wherein the A component is composed of: 38 parts of fast-setting and fast-hardening high Belite sulfoaluminate cement, Portland cement 14 parts, 0.9 part of hydration regulator, 4 parts of ultra-fine fly ash, 0.3 part of UEA expansion agent, 49 parts of fine aggregate, 0.25 part of lignosulfonate water reducing agent, 0.1 part of silicone defoamer, hydroxyl 0.02 part of propyl methylcellulose, 0.02 part of redispersible latex powder, 1 part of calcium nitrite, the composition of component B is: 46 parts of ultra-high strength sulfoaluminate cement, 7 parts of anhydrite, and amorphous calcium aluminate 3 parts of phase, 4 parts of ultra-fine fly ash, 46 parts of fine aggregate, 0.1 part of lithium carbonate, 0.2 part of boric acid, 0.3 part of lignosulfonate water reducing agent, 0.1 part of silicone defoamer, hydroxypropyl methane 0.02 part of base cellulose, 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com