High-flash-point environment-friendly diluent and preparation method and application thereof

A diluent, high flash point technology, applied in the direction of coating, etc., can solve the problems of poor paint dilution effect, low flash point, poor resin compatibility, etc., achieve dense paint film, fast film forming speed, and reduce system viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

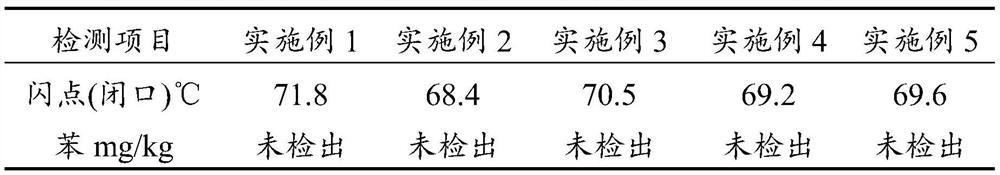

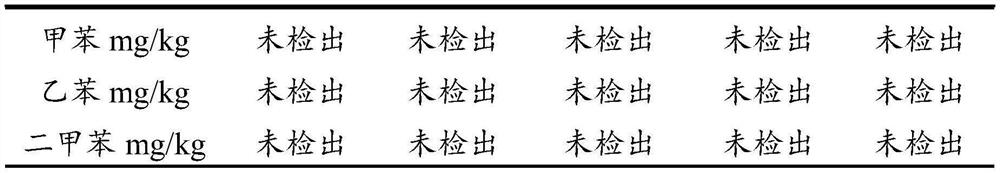

Examples

preparation example Construction

[0037] The present invention also provides a kind of preparation method of high-flash point environment-friendly diluent, comprising the following steps:

[0038] Mix tripropylene glycol ether, cyclohexanediol monomethyl ether, butyl orthosilicate, dipropylene glycol methyl ether and acetate, stir at a stirring rate of 200-500r / min for 30-80min, and let stand for 10-50min to obtain high Flash point environmentally friendly thinner.

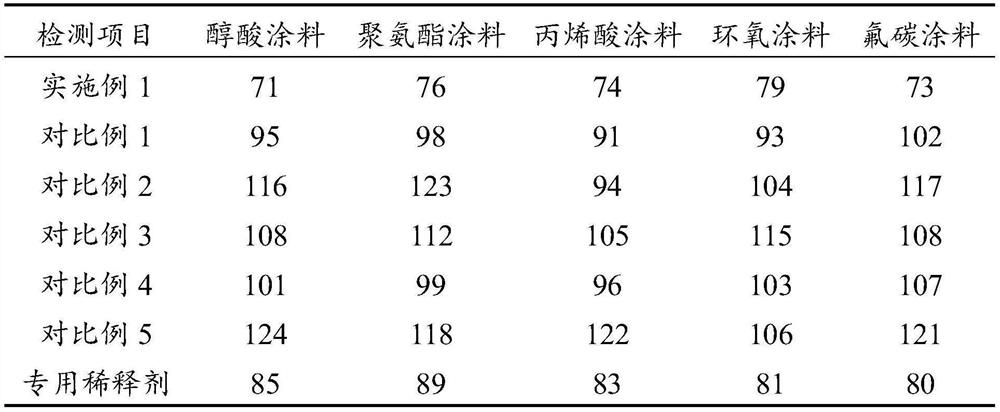

[0039] The invention also provides the application of a high-flash point environment-friendly diluent in thinning paint.

[0040] Preferably, in the application of the above-mentioned high-flash point environmentally friendly diluent, the coating includes alkyd coating, polyurethane coating, acrylic coating, epoxy coating, epoxy ester coating, fluorocarbon coating, steel structure fireproof coating, general floor paint, road marking paint or reflective paint.

Embodiment 1

[0042] The present invention provides a high-flash point environment-friendly diluent, which is prepared from the following raw materials in parts by mass: 23 parts of tripropylene glycol butyl ether, 35 parts of tripropylene glycol methyl ether, 25 parts of cyclohexanediol monomethyl ether, orthosilicon 12 parts of butyl ester, 15 parts of dipropylene glycol methyl ether, and 15 parts of dipropylene glycol methyl ether acetate.

[0043] The preparation method is: mix tripropylene glycol butyl ether, tripropylene glycol methyl ether, cyclohexanediol monomethyl ether, butyl orthosilicate, dipropylene glycol methyl ether, dipropylene glycol methyl ether acetate, and stir at a stirring rate of 200r / min for 80min , standing for 10 minutes, that is, a high-flash point environmentally friendly diluent.

Embodiment 2

[0045] The present invention provides a high-flash point environment-friendly diluent, which is prepared from the following raw materials in parts by mass: 40 parts of tripropylene glycol butyl ether, 20 parts of cyclohexanediol monomethyl ether, 10 parts of orthobutyl silicate, 10 parts of propylene glycol methyl ether, 8 parts of dipropylene glycol methyl ether acetate.

[0046]The preparation method is: mix tripropylene glycol butyl ether, cyclohexanediol monomethyl ether, butyl orthosilicate, dipropylene glycol methyl ether, and dipropylene glycol methyl ether acetate, stir at a stirring rate of 300r / min for 60min, and let stand for 20min. That is, a high-flash point environmentally friendly diluent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com