Application of easy-to-clean acrylic finish paint in refrigerated container

A technology of acrylic topcoat and refrigerated containers, which is applied in the direction of surface coating liquid devices, coatings, anti-corrosion coatings, etc., which can solve the problem of not being able to effectively prevent heat from entering refrigerated containers, affecting the secondary sales of refrigerated containers, and the effect of container refrigeration To achieve the effect of ensuring easy-cleaning characteristics, good application prospects, and improving easy-cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

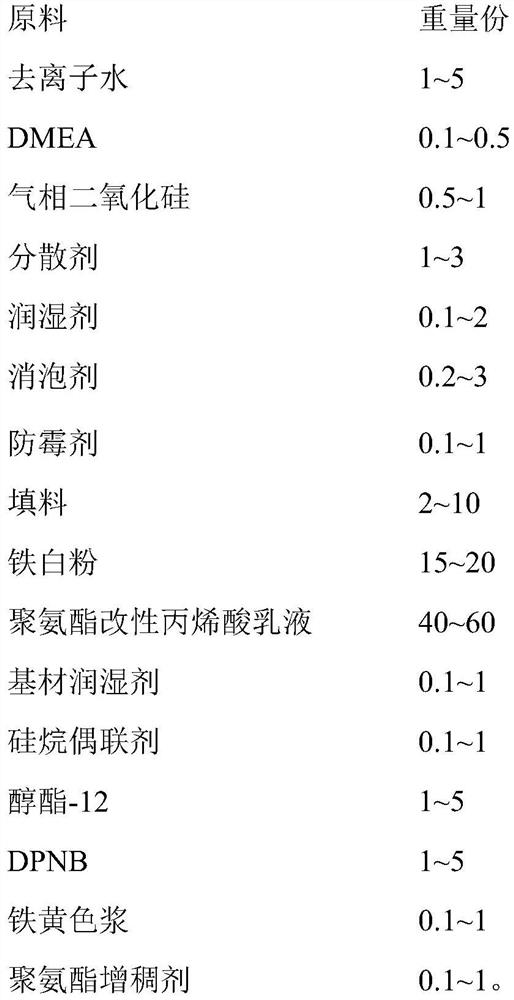

[0037] An easy-to-clean acrylic topcoat prepared from the following raw materials:

[0038]

[0039] In the present embodiment, the preparation method of the easy-to-clean acrylic topcoat is as follows:

[0040] (1) Add deionized water into the container, and add DMEA, fumed silica, dispersant, wetting agent, defoamer (0.2g, of which silicone defoamer 0.1g), antifoam Mold agent, continue stirring at 550r / min for 5min to obtain mixture 1;

[0041] (2) Add filler and titanium dioxide to mixture 1 under stirring conditions, then stir at 600r / min for 15min, and then grind until the fineness is not greater than 40 μm to obtain mixture 2;

[0042] (3) Under stirring conditions, add polyurethane-modified acrylic emulsion, substrate wetting agent, 0.1g defoamer, silane coupling agent, alcohol ester-12, DPNB, iron yellow slurry to mixture 2, and stir for 15 minutes to obtain Mixture 3;

[0043] (4) Add a polyurethane thickener to the mixture 3 to adjust the viscosity and solid co...

Embodiment 2~4

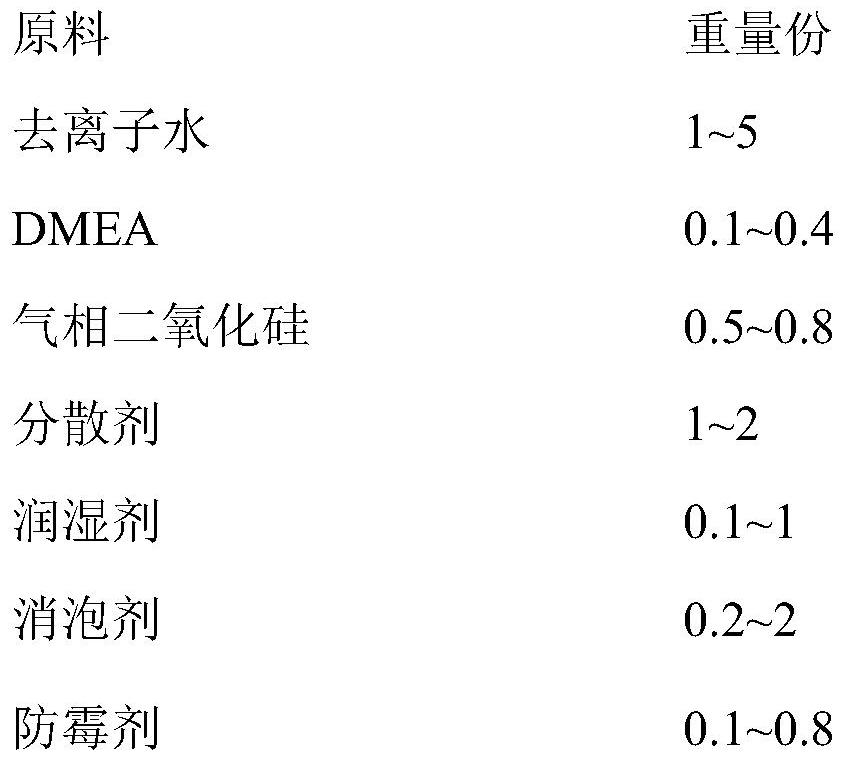

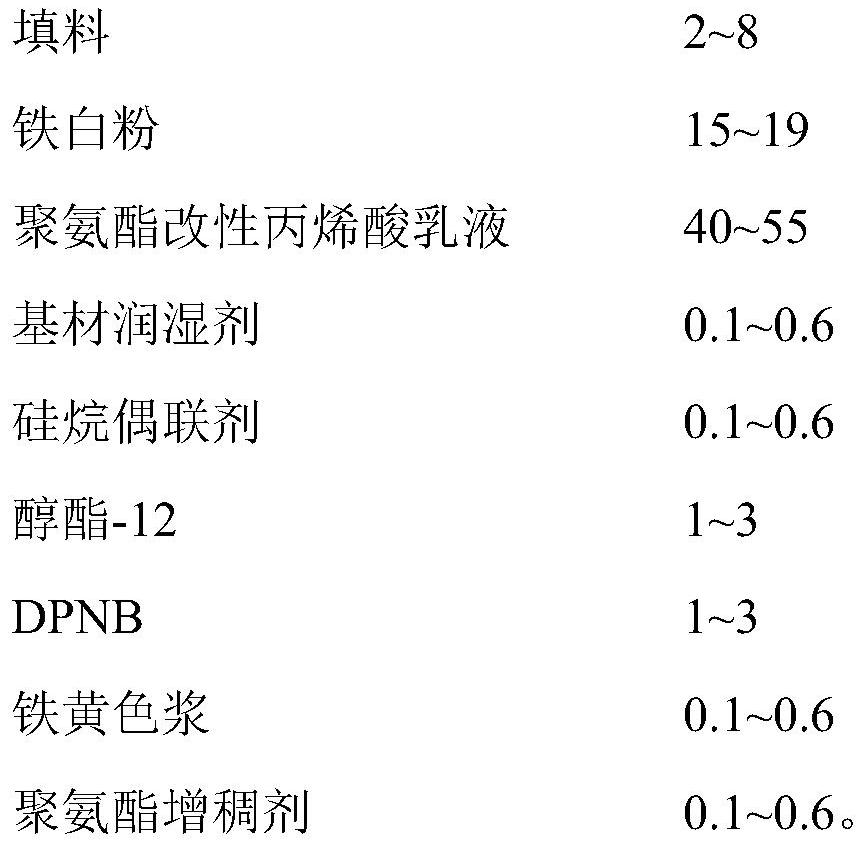

[0051] In Examples 2-4, the easy-to-clean acrylic topcoat is prepared from the following raw materials:

[0052] The preparation raw material of table 1 embodiment 2~4 (unit: g)

[0053] raw material Example 2 Example 3 Example 4 Deionized water 3 4 5 DMEA 0.2 0.2 0.3 fumed silica 0.6 0.7 0.8 Dispersant 1.3 1.5 1.6 lubricant 0.4 0.6 0.8 Defoamer 0.5 0.7 0.9 antifungal agent 0.3 0.4 0.5 filler 4 5 6 Iron white powder 16 17 18 Polyurethane modified acrylic emulsion 45 50 55 Substrate wetting agent 0.2 0.3 0.4 A silane coupling agent 0.2 0.3 0.4 Alcohol Ester-12 1.8 2 2.4 DPNB 1.4 1.6 1.8 iron yellow paste 0.2 0.3 0.4 polyurethane thickener 0.2 0.3 0.3

[0054] The preparation method of the easy-to-clean acrylic topcoat in Examples 2-4 is all the same except that the dosage is different.

[0055] Especially low, in the preparation proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com