Fermentation technology of bacterial enzyme feed

A fermentation process and feed technology, applied in the field of fermentation process of bacterial enzyme feed, can solve the problems affecting animal feed intake, digestion and absorption rate, loss of activity, and inability to consume the feed at one time, and achieve good storage stability and stimulation. Effects of feed intake and improved storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

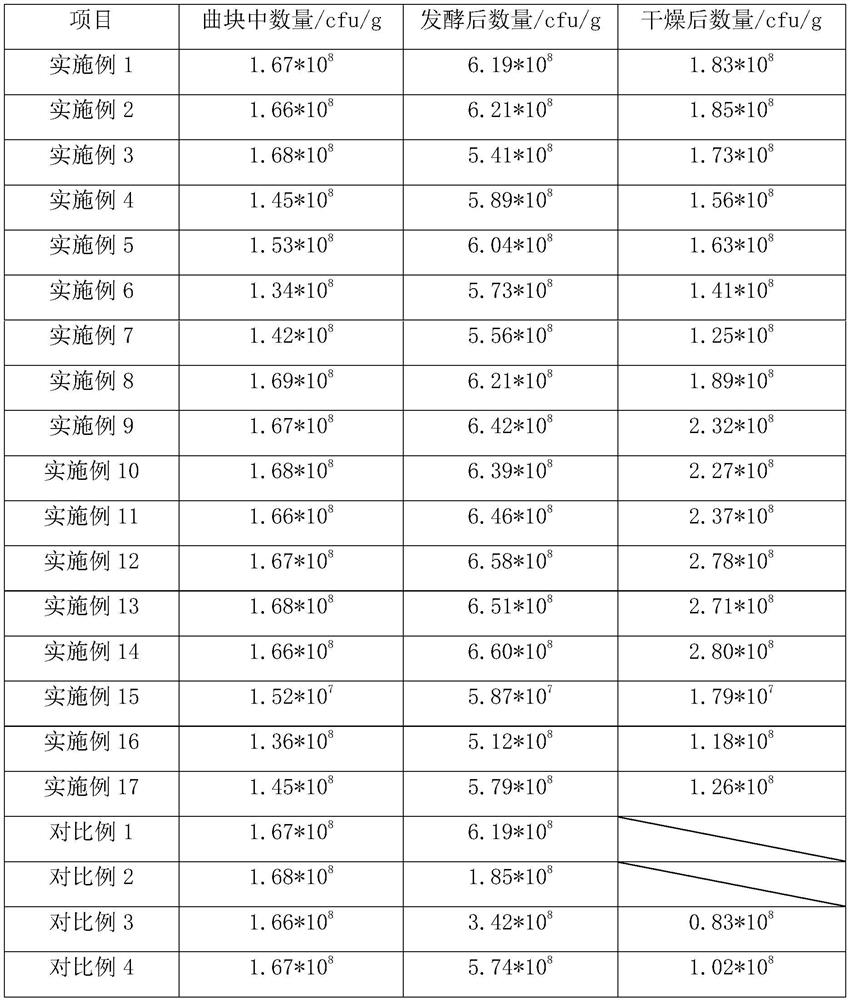

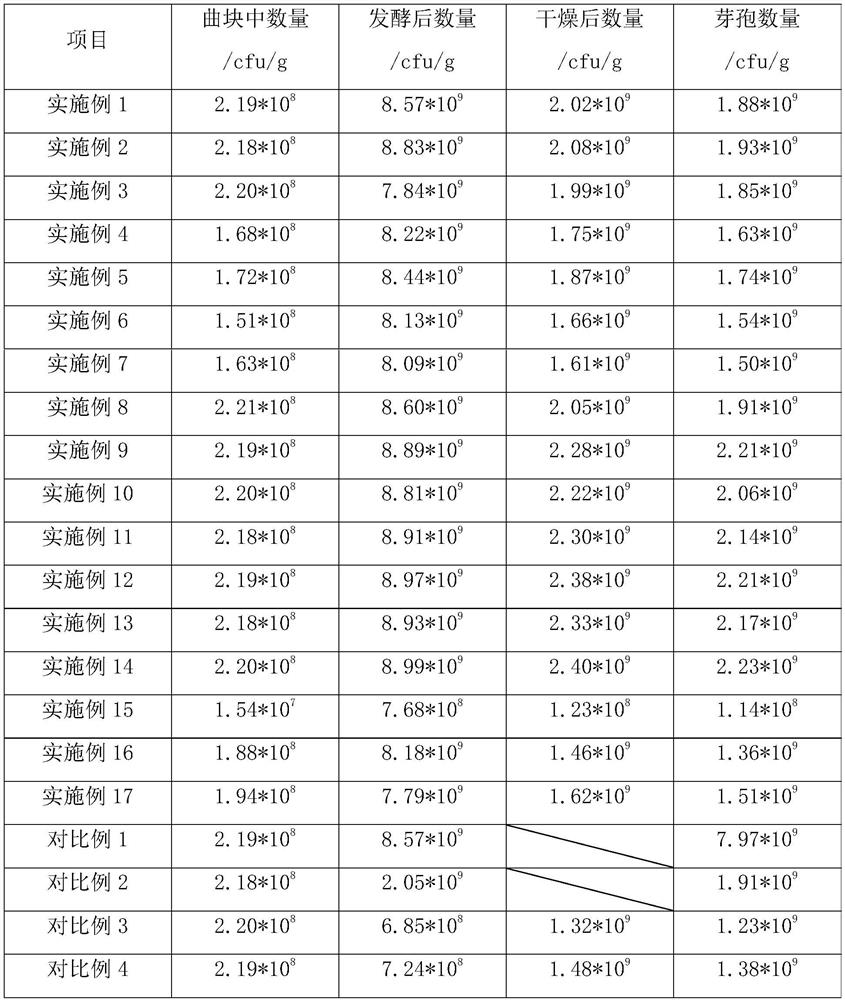

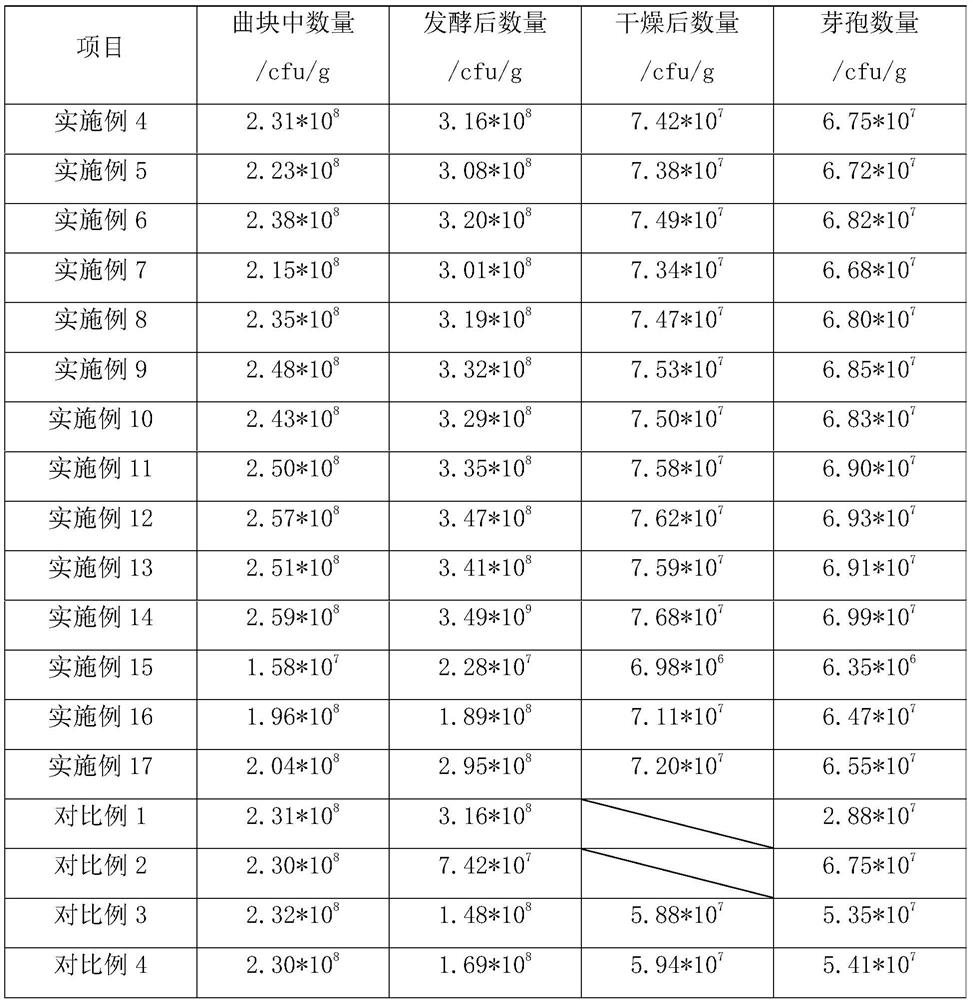

Examples

preparation example 1

[0051] Preparation example 1: Modified bamboo powder is prepared by the following method:

[0052] Configuration mass fraction 2% gelatin aqueous solution, adopt coating machine to spray gelatin aqueous solution to the surface of bamboo powder, gelatin aqueous solution and bamboo powder weight ratio are 1:4.2, make modified bamboo powder after drying; Bamboo powder passes 80 mesh sieves.

preparation example 2

[0053] Preparation example 2: the difference between this preparation example and preparation example 1 is:

[0054] The weight ratio of gelatin aqueous solution to bamboo powder is 1:3.

preparation example 3

[0055] Preparation Example 3: The difference between this preparation example and Preparation Example 1 is:

[0056] The weight ratio of gelatin aqueous solution to bamboo powder is 1:5.5.

[0057] Example of preparation of curved block

[0058] The yeast in the following raw materials was purchased from Saccharomyces cerevisiae produced by Qingdao Gengen Biotechnology Group Co., Ltd.; Bacillus subtilis was purchased from the Bacillus subtilis powder produced by Qingdao Gengen Biotechnology Group Co., Ltd., the model is CT-10; Clostridium butyricum The Clostridium butyricum bacteria powder produced by Qingdao Gengen Biotechnology Group Co., Ltd. was purchased; other raw materials and equipment were commercially available.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grinding fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap