A preparation method of two-dimensional molybdenum ditelluride nanomaterials by confined chemical vapor deposition

A chemical vapor deposition and nanomaterial technology, applied in the field of confined chemical vapor deposition preparation of two-dimensional molybdenum ditelluride nanomaterials, can solve the problems of low experiment repetition rate, low chemical reaction driving force, poor product stability, etc. Broad application prospects, good experimental stability, and stable and controllable processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

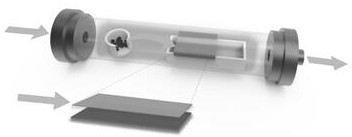

[0045] Preparation of MoTe by Chemical Vapor Deposition 2 method, including the following steps:

[0046] 1) Perform hydrophilic pretreatment on the growth substrate: Cut the silicon substrate with a 280nm thick oxide layer into two silicon wafers with a size of 2cm×1.5cm, and put them in a plasma cleaning machine for surface treatment to make them have Hydrophilicity, set the parameters of the oxygen plasma cleaning machine to the oxygen flow rate of 400sccm, the plasma cleaning power to 40W, and the cleaning time to 50s;

[0047] 2) Introduce sodium molybdate as a molybdenum source: prepare a sodium molybdate solution with a concentration of 0.02 mol / L, put the beaker containing the solution into an ultrasonic instrument, and perform ultrasonication for 5 minutes to make the solution uniform. Put the silicon wafer obtained in step 1 on the spin coater, turn on the vacuum pump to suck it and fix it in the middle of the spin coater, set the spin coater parameters as the first...

Embodiment 2

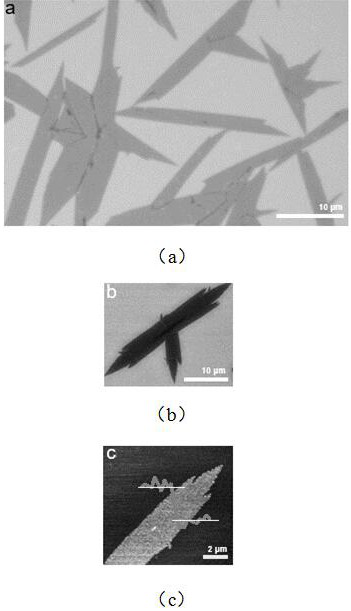

[0052] Embodiment 2: namely the comparative example of the present invention, the operation steps are the same as above, the difference is that the slit spacing of two stacked silicon wafers is set to 520 microns, and its product is as follows Figure 7 As shown, the size of the product is smaller, the nucleation density is lower, and the morphology is close to one-dimensional. Compared with the product in the confined environment (slit spacing of 1-30 μm), it proves that the confined chemical vapor deposition The method is beneficial to the growth of the product, and increases the nucleation density and grain size of the product.

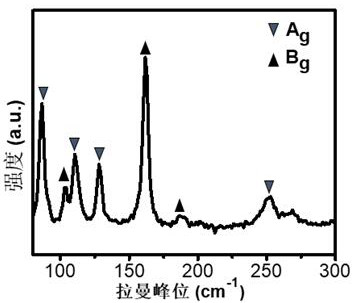

[0053] Examples 2-15 mainly study the preparation of two-dimensional MoTe by chemical vapor deposition 2 During the process, the carrier gas flow rate, confinement slit size, substrate pair synthesis of 2D MoTe 2 The impact of the product, including its size, nucleation density, coverage, thickness, shape, phase, etc. The specific implementation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com