Air-core coil sensing complementary device, pincerlike multimeter and preparation method of pincerlike multimeter

A multimeter and coil technology, applied in the direction of transformer/inductor coil/winding/connection, inductor, multi-tester circuit, etc., can solve the problems of complicated manufacturing process, different signal size of integrator circuit, weak induction potential, etc. Achieve the effect of meeting the production process requirements, improving position difference defects, and increasing voltage strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

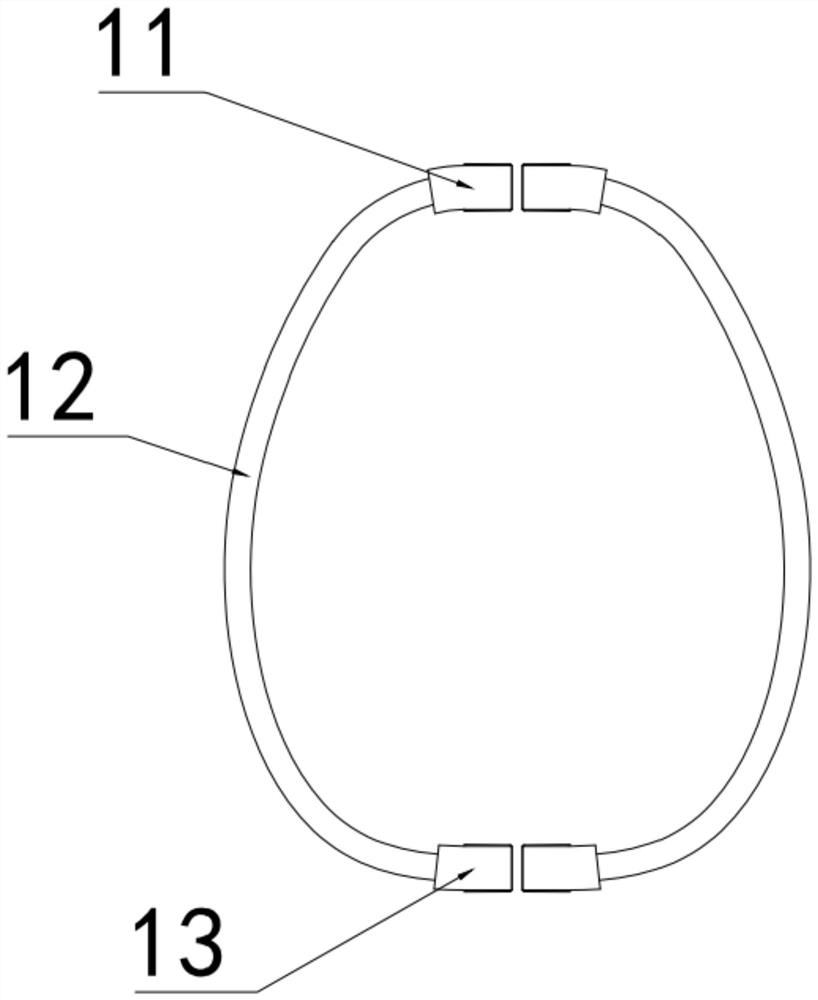

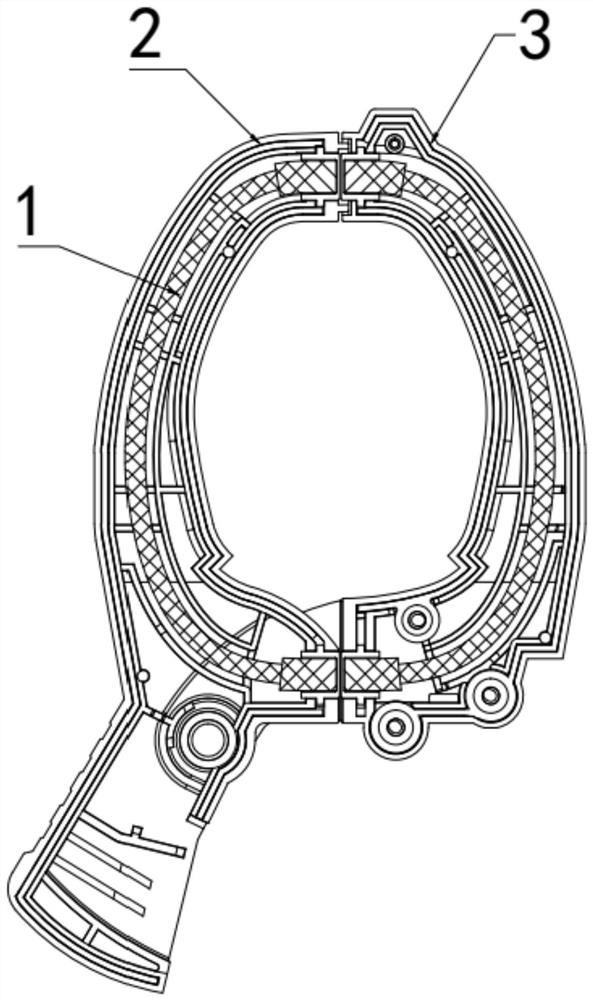

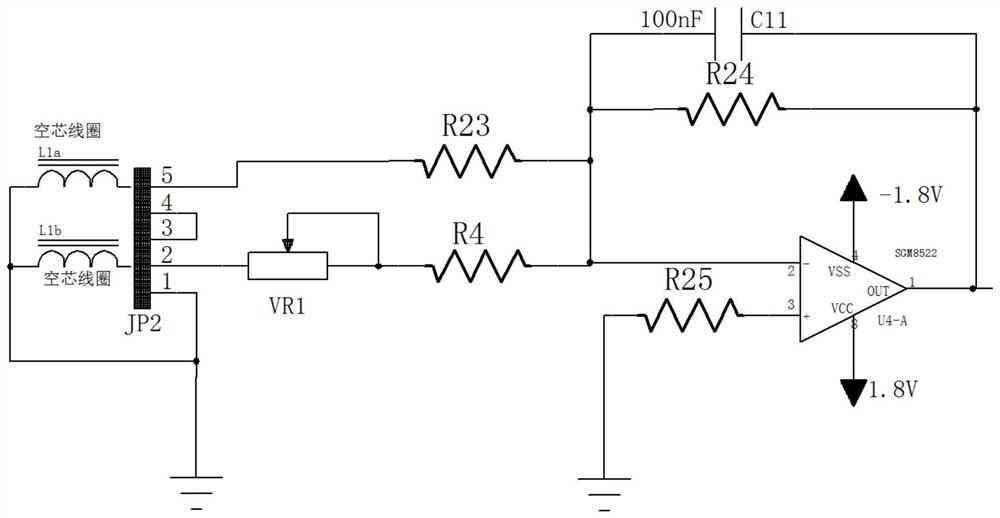

[0041] Example: see figure 1 , an air core coil sensing complementary device provided in this embodiment, which includes two sets of parallel winding coils, the winding coils include a special-shaped hollow frame 1 and an air core wound on the special-shaped hollow frame 1 Coil;

[0042] The special-shaped hollow skeleton 1 includes an integrally formed first thickened skeleton part 11, an intermediate skeleton 12, and a second thickened skeleton part 13. The first thickened skeleton part 11 and the second thickened skeleton part 13 The cross-sectional diameters are all larger than the cross-sectional diameter of the intermediate skeleton 12; specifically, the special-shaped hollow skeleton 1 is a plastic skeleton to prevent magnetic saturation;

[0043] The air-core coil includes a first section, a second section, and a third section respectively extended and formed according to the shapes of the first skeleton thickened part 11, the middle skeleton 12, and the second skele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com