Preparation method of cobaltosic oxide and carbon quantum dot composite material

A technology of cobalt tetroxide and carbon quantum dots, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high cost, complicated process of ORR oxygen evolution cathode catalyst, etc., and achieve low cost, improved electrochemical performance, and improved electrocatalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

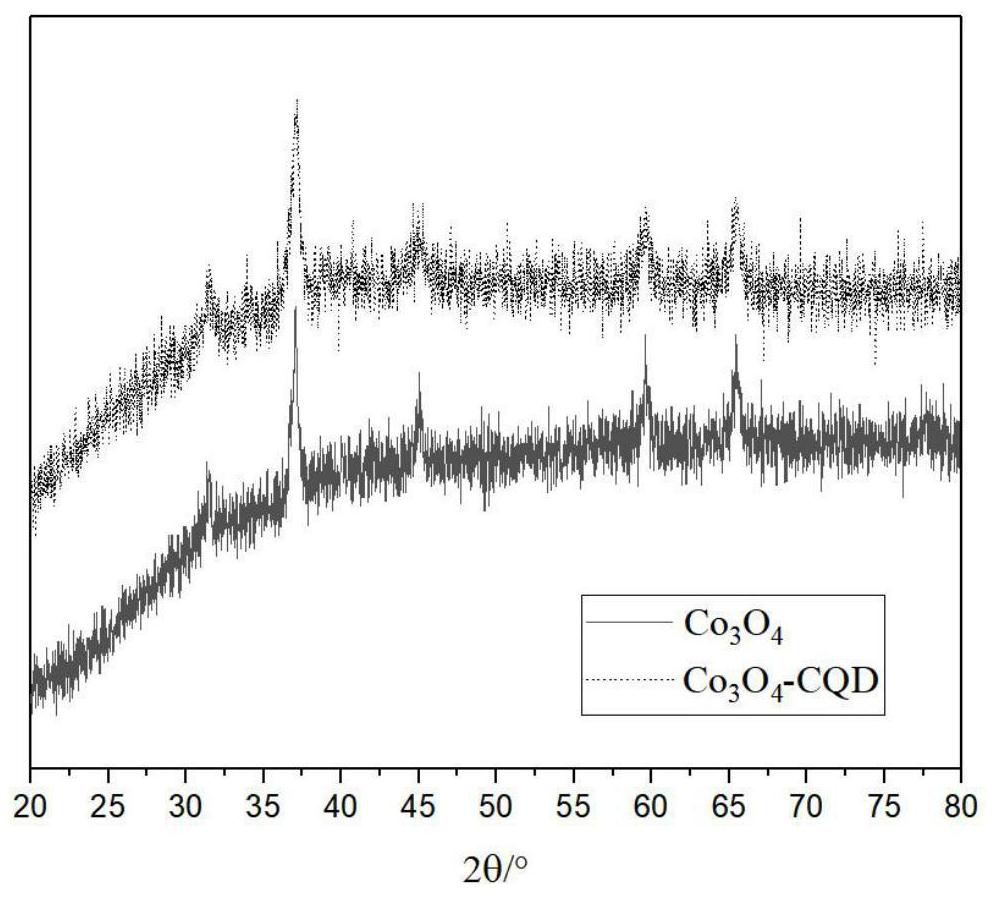

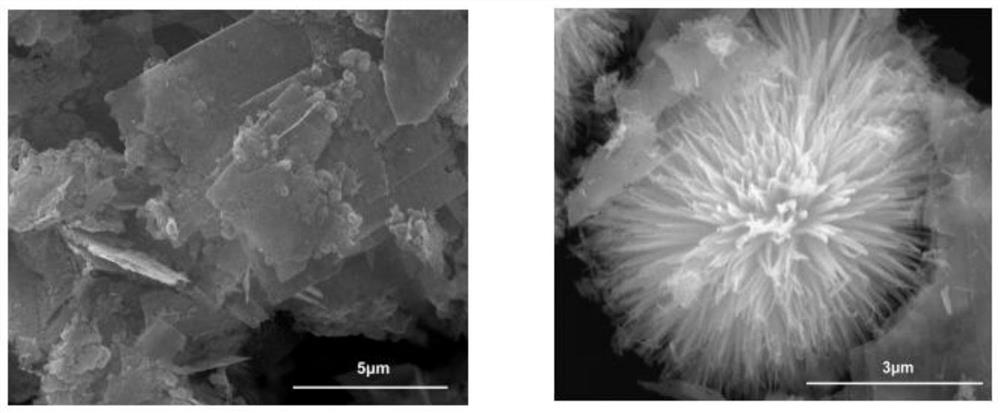

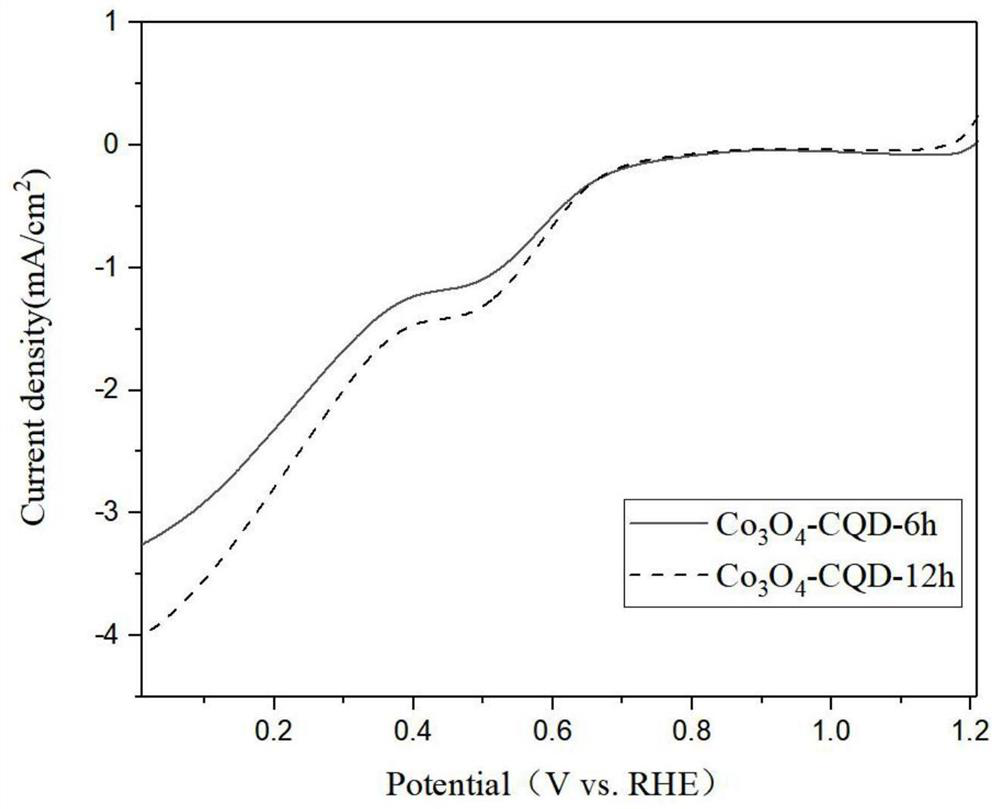

[0028] refer to Figure 1-3 , a preparation method of tricobalt tetroxide and carbon quantum dot composite material, comprising the following steps:

[0029] S1. Add 1.5g of disposable chopsticks sawdust to deionized water, stir evenly, transfer to a 100ml reaction kettle, and react at 180°C for 6h to obtain a turbid carbon quantum dot solution;

[0030] S2. Suction filter the turbid carbon quantum dot solution obtained in step S1 with a filter membrane of 0.22 μm;

[0031] S3, the solution obtained in step S2 was dialyzed for 2 days with a 500Da dialysis bag to obtain a carbon quantum dot solution;

[0032] S4, 25g carbon quantum dot solution obtained in step S3 is mixed with 176.5mg cobalt nitrate hexahydrate, 120mg urea, 145.6mg cetyltrimethylammonium bromide, 25g deionized water, and ultrasonically stirred evenly;

[0033] S5, the solution obtained in step S4 is transferred to a 100ml reactor for reaction, and reacted for 12h at 160° C. to generate basic cobalt carbonate...

Embodiment 1

[0042] A preparation method of tricobalt tetroxide / carbon quantum dot composite material, the specific steps are as follows:

[0043] Add 1.5g of disposable chopsticks sawdust to deionized water, stir evenly, transfer to a 100ml reaction kettle, and react at 180°C for 6h to obtain a turbid carbon quantum dot solution;

[0044] The turbid carbon quantum dot solution obtained in (1) is suction-filtered with a filter membrane of 0.22 μm;

[0045] The solution obtained in (2) was dialyzed for 2 days with a 500 Da dialysis bag to obtain a carbon quantum dot solution.

[0046] The 25g carbon quantum dot solution obtained in (3) was mixed with 176.5mg cobalt nitrate hexahydrate, 120mg urea, 145.6mg cetyltrimethylammonium bromide, 25g deionized water, and ultrasonically stirred evenly;

[0047] The solution obtained in (4) was transferred to a 100ml reactor for reaction, and reacted at 160° C. for 12 hours to generate basic cobalt carbonate;

[0048] The basic cobalt carbonate / carbo...

Embodiment 2

[0052] Add 1.5g of disposable chopsticks sawdust to deionized water, stir evenly, transfer to a 100ml reaction kettle, and react at 180°C for 12h to obtain a turbid carbon quantum dot solution;

[0053] The turbid carbon quantum dot solution obtained in (1) is suction-filtered with a filter membrane of 0.22 μm;

[0054] The solution obtained in (2) was dialyzed for 2 days with a 500 Da dialysis bag to obtain a carbon quantum dot solution.

[0055] The 25g carbon quantum dot solution obtained in (3) was mixed with 176.5mg cobalt nitrate hexahydrate, 120mg urea, 145.6mg cetyltrimethylammonium bromide, 25g deionized water, and ultrasonically stirred evenly;

[0056] The solution obtained by (4) is transferred to a 100ml reactor for reaction, and reacted for 6h at 160°C to generate basic cobalt carbonate;

[0057] The basic cobalt carbonate / carbon quantum dot solution obtained in (5) was centrifuged for 10min at a speed of 8000rmp, and the precipitate was taken;

[0058] The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com