Polymer microneedle and preparation method thereof

A polymer and polymer solution technology, applied in the field of biomedical materials, can solve the problems of affecting the quality and use effect of polymer microneedles, limiting the mechanical properties of polymer microneedles, poor mechanical properties, etc., to achieve enhanced transdermal efficiency, Improves mechanical properties and improves moisture retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

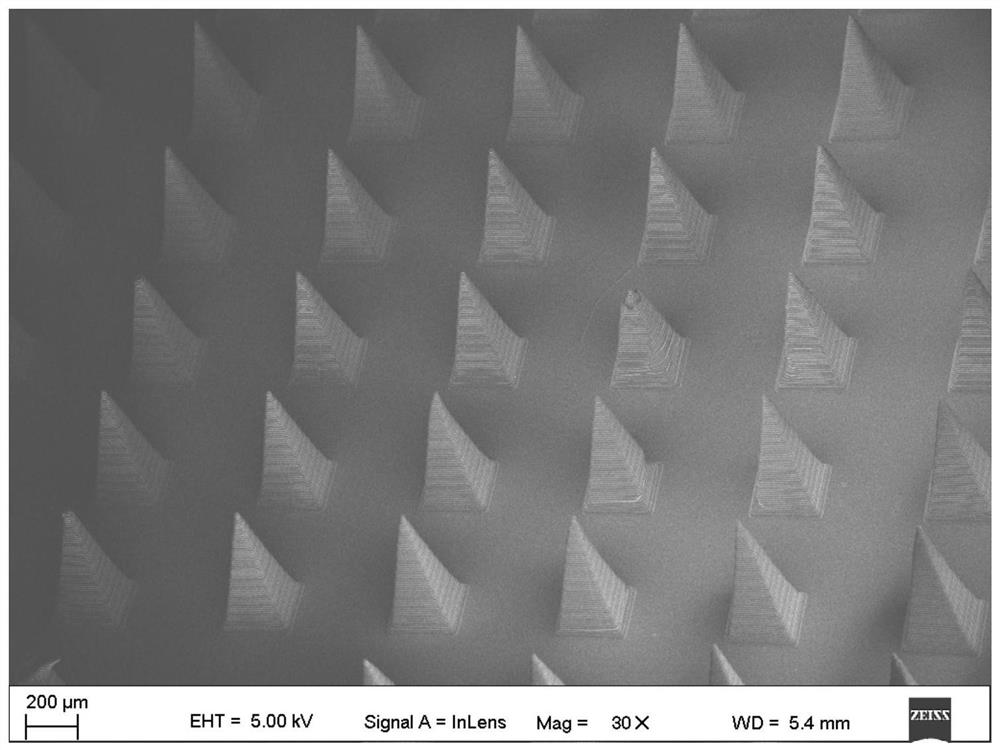

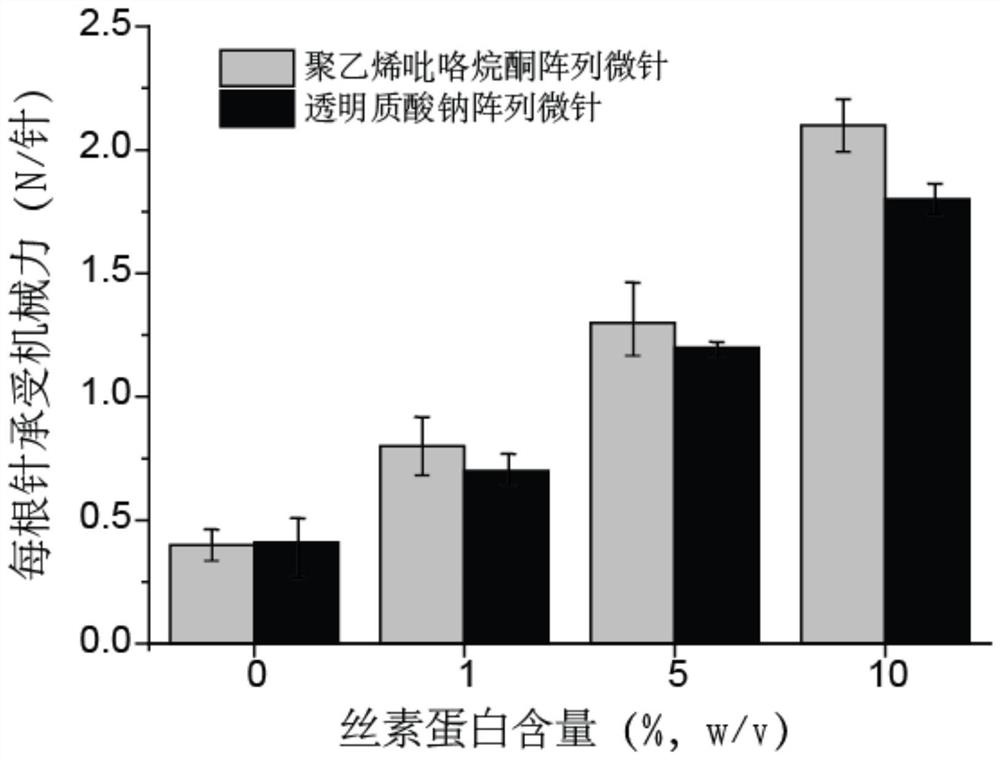

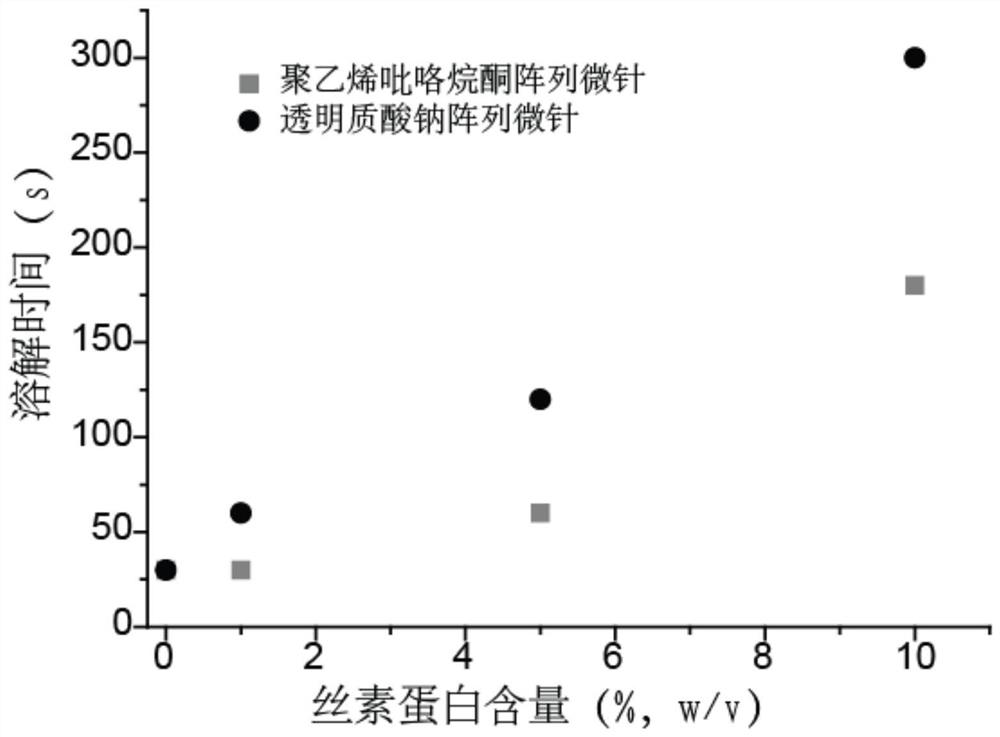

[0041] In this example, polyvinylpyrrolidone polymer microneedles doped with different concentrations of silk fibroin were prepared, and the effects of different concentrations of silk fibroin doping on the performance of polymer microneedles were analyzed, as follows:

[0042] 1) Pretreatment of silk fibroin: Weigh 10g of silk protein powder and suspend it in 400mL of 0.5% NaHCO 3 solution, after soaking at room temperature for 24 hours, stirring and degumming in a water bath at 100°C for 2 hours; after the above solution was vacuum filtered, the filter cake was resuspended in 400mL of CaCl 2 、H 2 In a mixed solvent of O and absolute ethanol (EtOH), stir and soak at room temperature for 48 hours; raise the temperature of the water bath to 100°C and maintain for 2 hours to dissolve. Transfer the above solution to a cellulose dialysis bag (2 ; The solution in the above-mentioned dialysis bag is freeze-dried to obtain the water-soluble silk fibroin of this example. Among them,...

Embodiment 2

[0047] In this example, sodium hyaluronate polymer microneedles doped with different concentrations of silk fibroin were prepared, and the effects of different concentrations of silk fibroin doping on the performance of polymer microneedles were analyzed, as follows:

[0048] 1) Pretreatment of silk fibroin: Weigh 10g of silk protein powder and suspend it in 400mL of 0.5% NaHCO 3 solution, after soaking at room temperature for 24 hours, stirring and degumming in a water bath at 100°C for 2 hours; after the above solution was vacuum filtered, the filter cake was resuspended in 400mL of CaCl 2 、H 2 In a mixed solvent of O and absolute ethanol (EtOH), stir and soak at room temperature for 48 hours; raise the temperature of the water bath to 100°C and maintain for 2 hours to dissolve. Transfer the above solution to a cellulose dialysis bag (2 ; The solution in the above-mentioned dialysis bag is freeze-dried to obtain the water-soluble silk fibroin of this example. Among them, C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com