Flue gas denitration device

A denitrification and flue gas technology, applied in the field of flue gas denitrification treatment, can solve the problems of high catalytic efficiency, flue gas temperature fluctuation range, and inability to ensure catalyst in real time, and achieve stable and reliable work and strong denitrification catalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

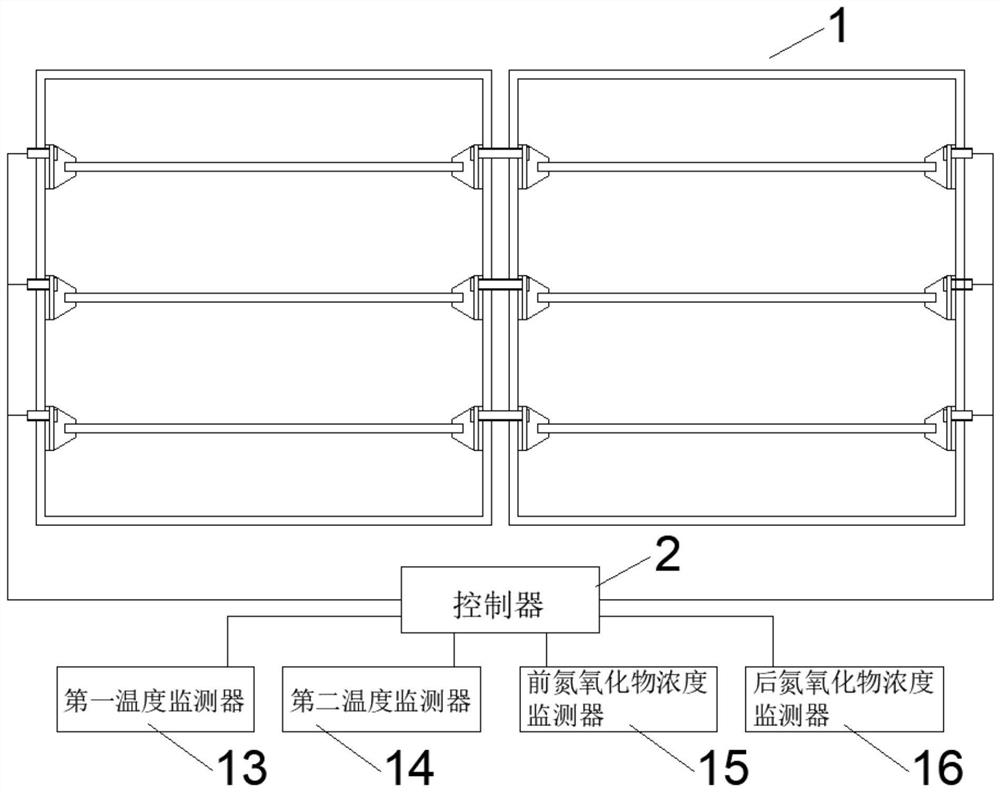

[0024] See attached Figure 1~4 . The flue gas denitration device includes a denitrification catalytic component 1, a monitoring component and a controller 2; the denitrification catalytic component 1 and the monitoring component are electrically connected to the controller 2 respectively; the denitrification catalytic component 1 is used to catalyze nitrogen oxidation in the flue gas The monitoring component is used to monitor the catalytic environment and / or catalytic capacity of the denitrification catalytic component 1, and transmits the monitoring information to the controller 2; the controller 2 is used to control the temperature of the denitrification catalytic component 1 according to the monitoring information . It can be seen from the above structure that this flue gas denitrification device is installed in the SCR reactor; when the temperature of the flue gas at the tail of the boiler is low, the flue gas flowing through the denitrification catalytic component 1 ca...

Embodiment 2

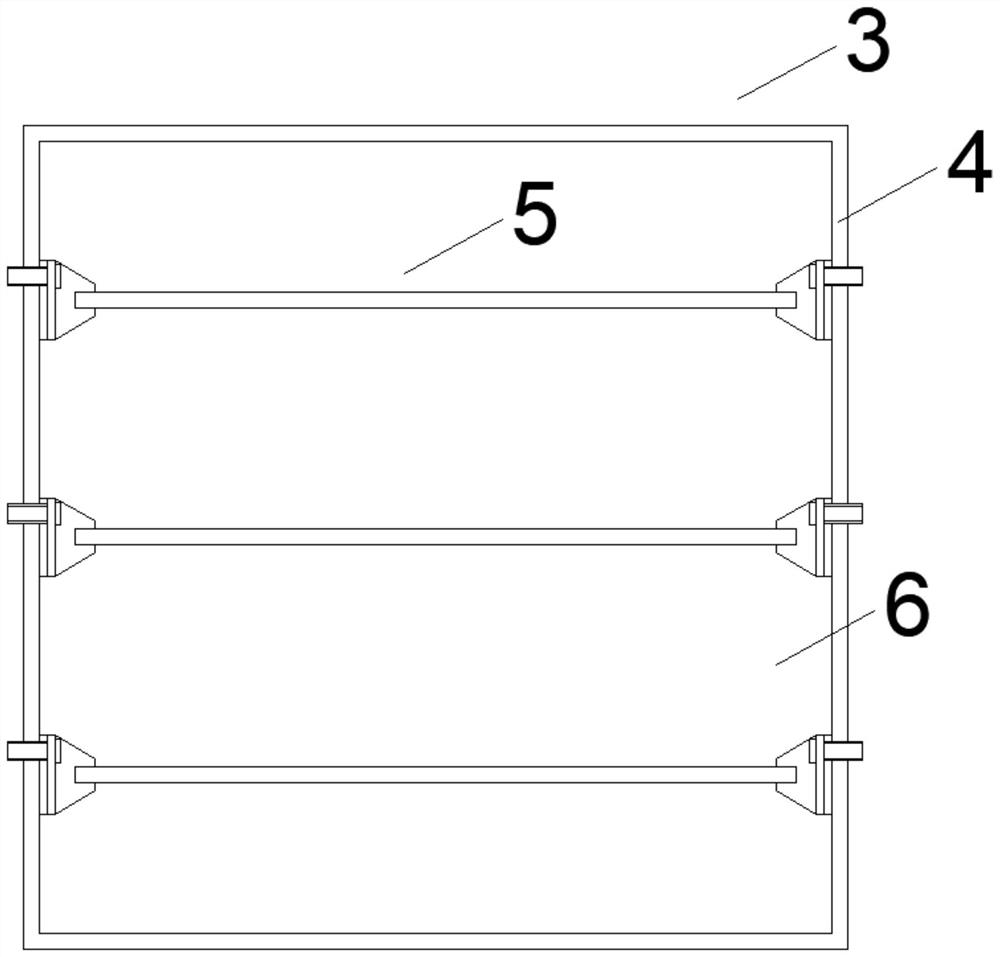

[0026] See attached Figure 1~4 . On the basis of Embodiment 1, the denitration catalytic assembly 1 includes at least one denitration catalytic unit 3; the denitration catalytic unit 3 includes a casing 4 and several catalytic mesh assemblies 5; the casing 4 is surrounded by a catalytic flue 6 ; The catalytic flue 6 is provided with a number of catalytic mesh components 5 . It can be seen from the above structure that the shell 4 is surrounded by a catalytic flue 6, so when the flue gas passes through the denitrification catalytic unit 3, it flows through the determined catalytic flue 6, and the catalytic flue 6 is provided with several catalytic mesh assemblies 5 for the flue gas. Catalytic denitrification of gas.

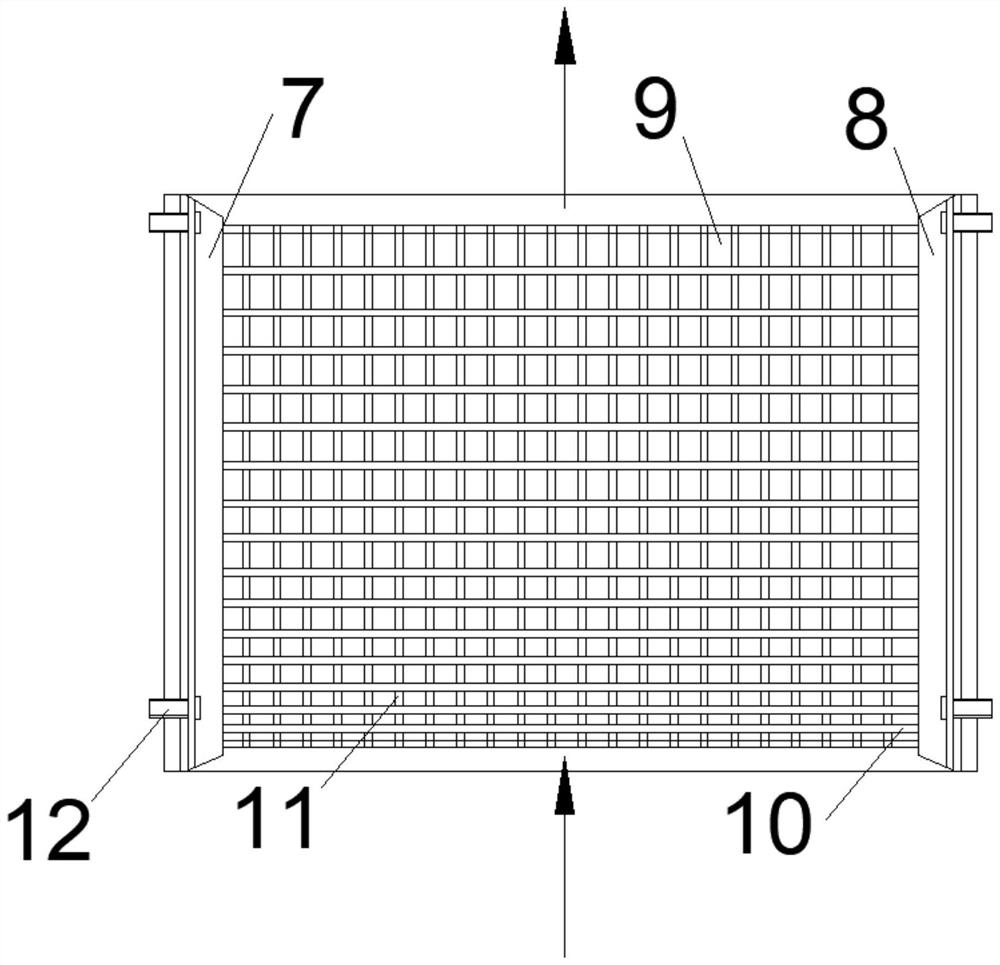

[0027] The catalytic grid assembly 5 includes a left conductive rail 7, a right conductive rail 8 and an electric heating grid 9; the left and right conductive rails 9 of the electric heating grid 9 are respectively connected to the left conductive rail 7 and t...

Embodiment 3

[0029] See attached Figure 1~4 . On the basis of Embodiment 2, the electric heating network 9 includes several electric heating wires 10 and several heat conducting wires 11 with insulating sheaths; several electric heating wires 10 are parallel to each other; several heat conducting wires 11 are parallel to each other; The left end of the heating wire 10 is connected to the left conductive rail 7, and the right end is connected to the right conductive rail 8, and intersects with all the heating wires 11; several heating wires 10 and several heating wires 11 form a network together. It can be seen from the above structure that the left end of each heating wire 10 is connected to the left conductive rail 7, and the right end is connected to the right conductive rail 8. Each heating wire 10 is a path, so even if one heating wire 10 breaks down, it will not affect the entire heating wire 10. The electric heating network 9 is energized to generate heat, which is different from c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com