Production technology and production equipment for wooden door with smooth paint surface

A technology of production process and production equipment, which is applied in the field of production process and production equipment of lacquered smooth wooden doors, can solve the problems of heat loss, large power loss due to temperature loss, and poor sealing, etc., and achieves obvious beneficial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] Such as Figure 1 to Figure 4 As shown, the embodiment of the present application provides a production process for a painted smooth wooden door, which is characterized by the following steps:

[0112] S1. Plate drying: remove the raw material plates with cracks, and put the raw material plates with flat surface and no cracks into the drying kiln for spray steaming and heating drying. The time of spray steaming is 13-15min, and the time of heating and drying is 20- 24d, so that the moisture content of the dried plate is 10-12%;

[0113] S2. Pressing the board: using a planer to press the thickness of the board;

[0114] S3. Cutting: use precision panel saw to process the compacted board into door side and door core board of specific size;

[0115] S4. Sanding: Use a sanding machine to sand the surface of the door core board and the surface of the door edge;

[0116] S5, group frame: combine the door core board and the door edge to form a wooden door;

[0117] S6. Wo...

Embodiment 2

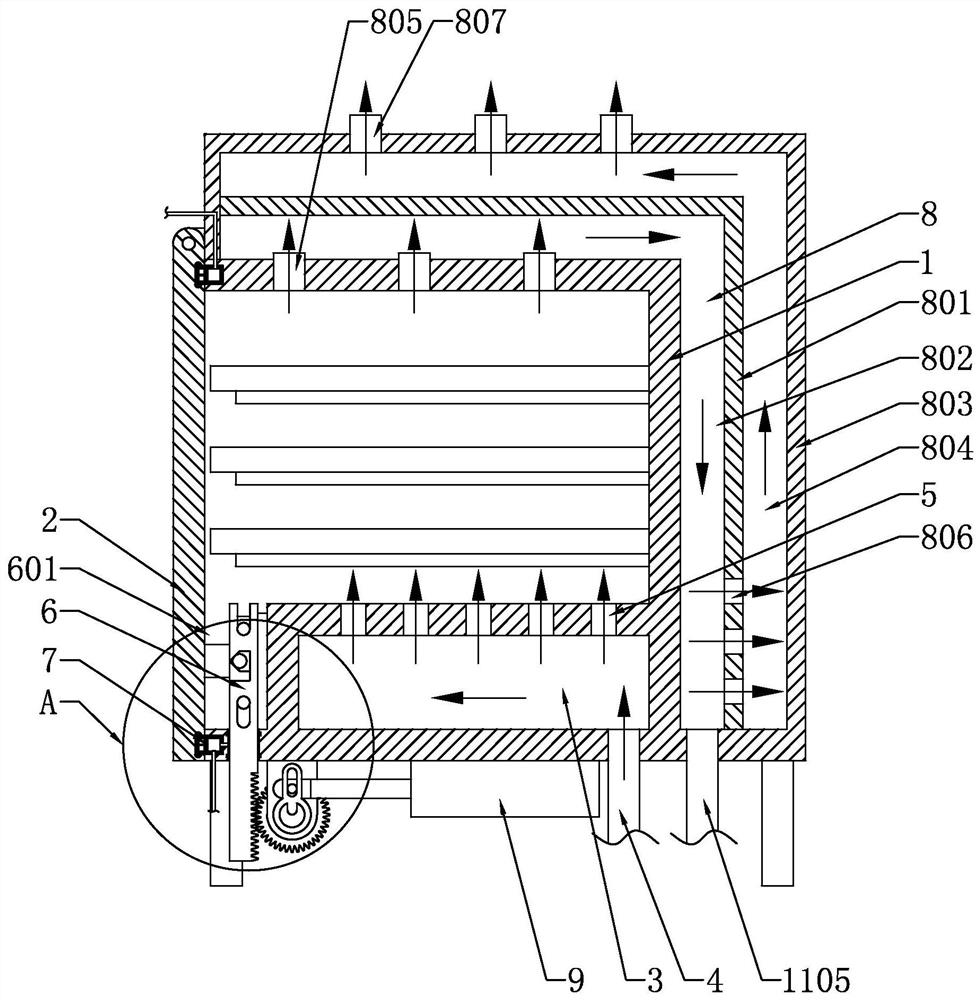

[0123] The embodiment of the present application also provides a kind of production equipment, it is characterized in that, comprises:

[0124] Drying box 1, which has an inner cavity and one side is open;

[0125] A box door 2, which is installed on one side of the drying box 1 for closing or opening the opening of the drying box 1;

[0126] A hot air chamber 3, which has an inner cavity and is arranged at the bottom of the inner cavity of the drying box 1;

[0127] A hot air pipe 4, which communicates with the inner cavity of the hot air chamber 3;

[0128] A hot air outlet 5, which communicates with the inner cavity of the hot air chamber 3 and the inner cavity of the drying box 1;

[0129] A door locking mechanism 6, which is used to fix between the closed door 2 and the drying box 1;

[0130] A sealing mechanism 7, which is used to seal between the box door 2 and the drying box 1;

[0131] The heat preservation mechanism 8 is used for heat preservation of the drying b...

Embodiment 3

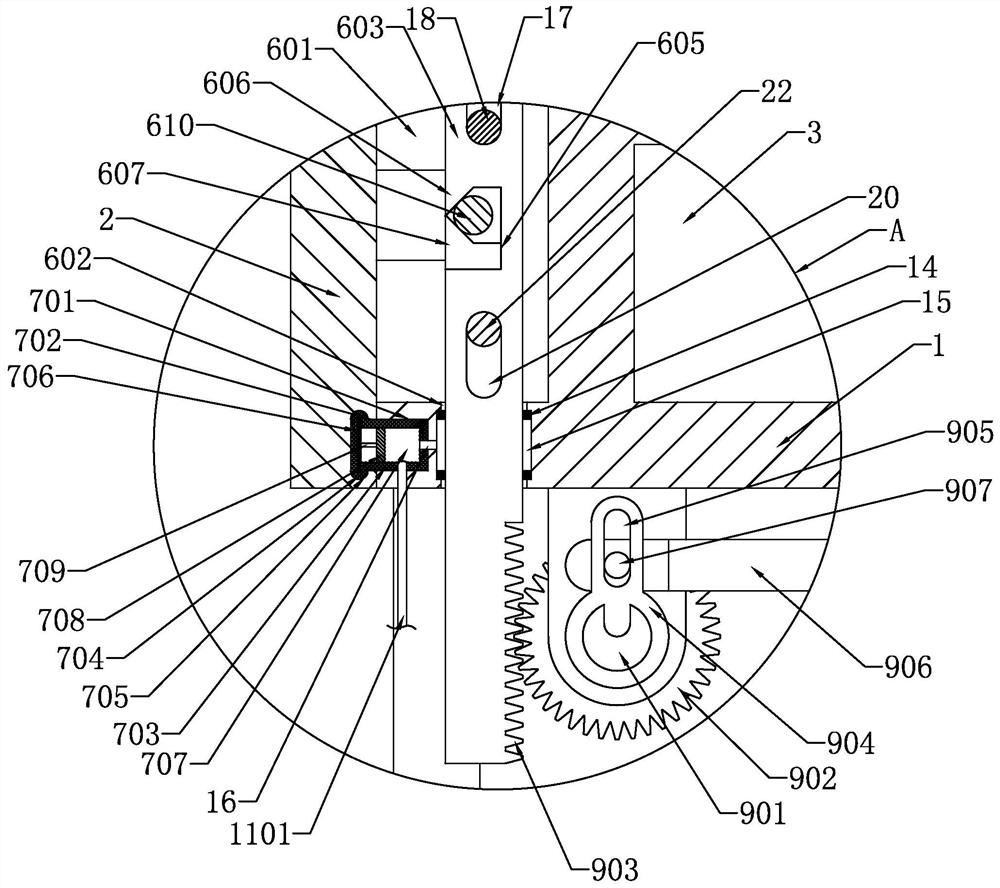

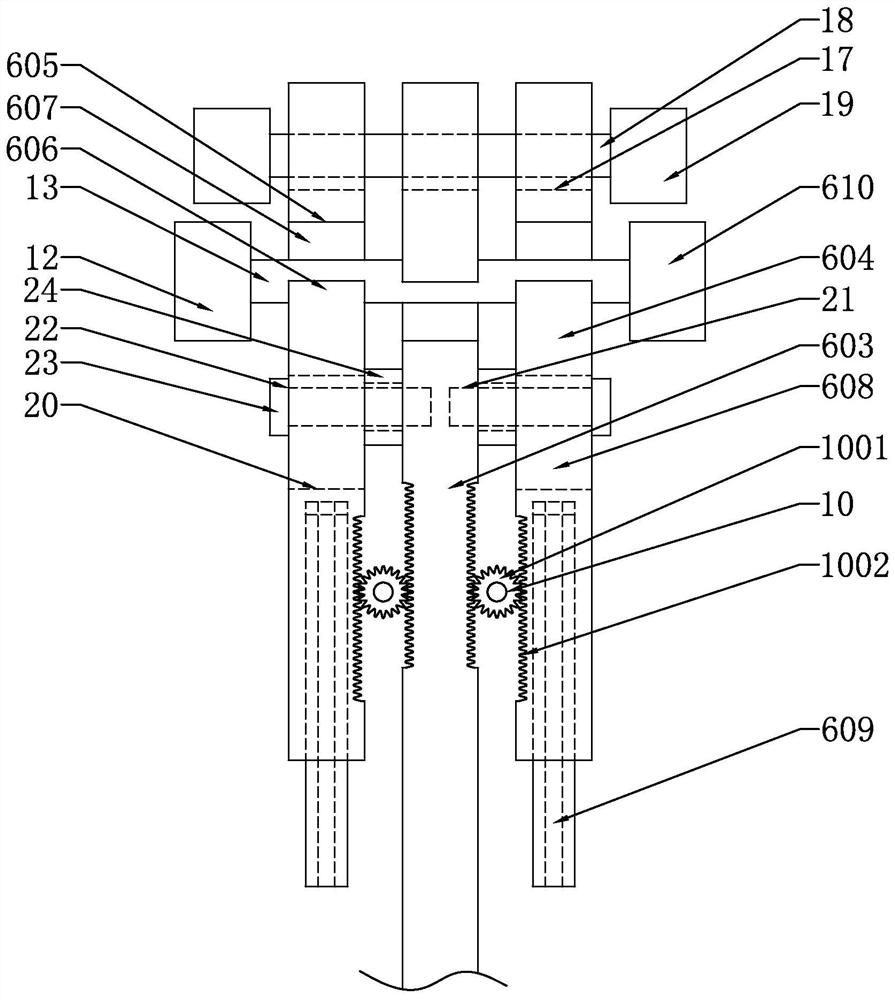

[0134] In this embodiment, in addition to the structural features of the foregoing embodiments, the door locking mechanism 6 includes:

[0135] Lock chamber 601, which is arranged between the side walls opposite to the door and the hot air chamber 3;

[0136] Lifting groove 602, which is arranged at the bottom of the drying box 1 and communicates with the lock chamber 601;

[0137] Main elevating rod 603, which is vertically slidably arranged in the elevating groove 602;

[0138] Auxiliary elevating rods 610, which have two and are respectively located on both sides of the main elevating rod 603;

[0139] A locking frame 604, which is installed on the inner wall of the box door 2 and is located in the lock chamber 601;

[0140] The locking groove includes a main groove 605, a triangular block 606 arranged on the inner wall of one side of the main groove 605, and a notch 607 between the bottom end of the triangular block 606 and the bottom end of the main groove 605;

[0141...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com