Polytrifluorochloroethylene resin composition

A technology of polychlorotrifluoroethylene and resin composition, which is applied in the application field of fluorine-containing polymers, can solve problems such as limitation of improvement effect, achieve good interfacial compatibility, improve processing performance, and improve melt fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

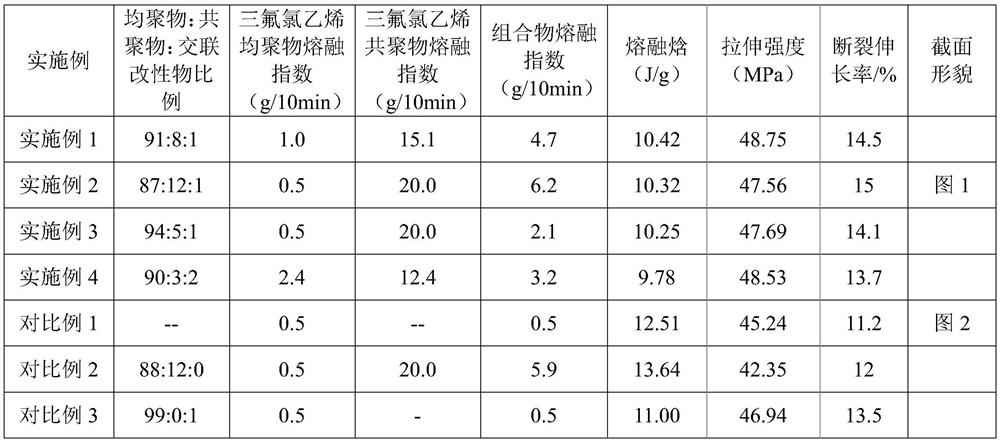

Embodiment 1

[0034] (1) Place the ethylene-chlorotrifluoroethylene binary copolymer powder in a blast oven at 150°C for 48 hours to obtain a cross-linked modified ECTFE powder (X-ECTFE);

[0035] (2) Obtain chlorotrifluoroethylene homopolymer suspension A and chlorotrifluoroethylene copolymer (comonomer tetrafluoroethylene) suspension B by suspension polymerization, wherein the melt index of chlorotrifluoroethylene homopolymer is 1.0g / 10min, the melt index of chlorotrifluoroethylene copolymer is 15.1g / 10min;

[0036] (3) Physically mix X-ECTFE obtained in step (1), suspension A and suspension B obtained in step (2), and add dispersant ethanol, wherein chlorotrifluoroethylene homopolymer, chlorotrifluoroethylene The mass ratio of copolymer and X-ECTFE is 91:8:1;

[0037] (4) filtering, washing and drying the mixed solution obtained in step (3) to finally obtain a mixed powder;

[0038] (5) The mixed powder obtained in step (4) is passed through a molding machine to make corresponding tes...

Embodiment 2

[0040] (1) Place the ethylene-chlorotrifluoroethylene binary copolymer powder in a blast oven at 180° C. for 96 hours to obtain cross-linked modified ECTFE powder (X-ECTFE);

[0041] (2) Obtain chlorotrifluoroethylene homopolymer suspension A and chlorotrifluoroethylene copolymer (comonomer ethylene) suspension B by suspension polymerization, wherein the melt index of chlorotrifluoroethylene homopolymer is 0.5g / 10min , the melt index of chlorotrifluoroethylene copolymer is 20.0g / 10min;

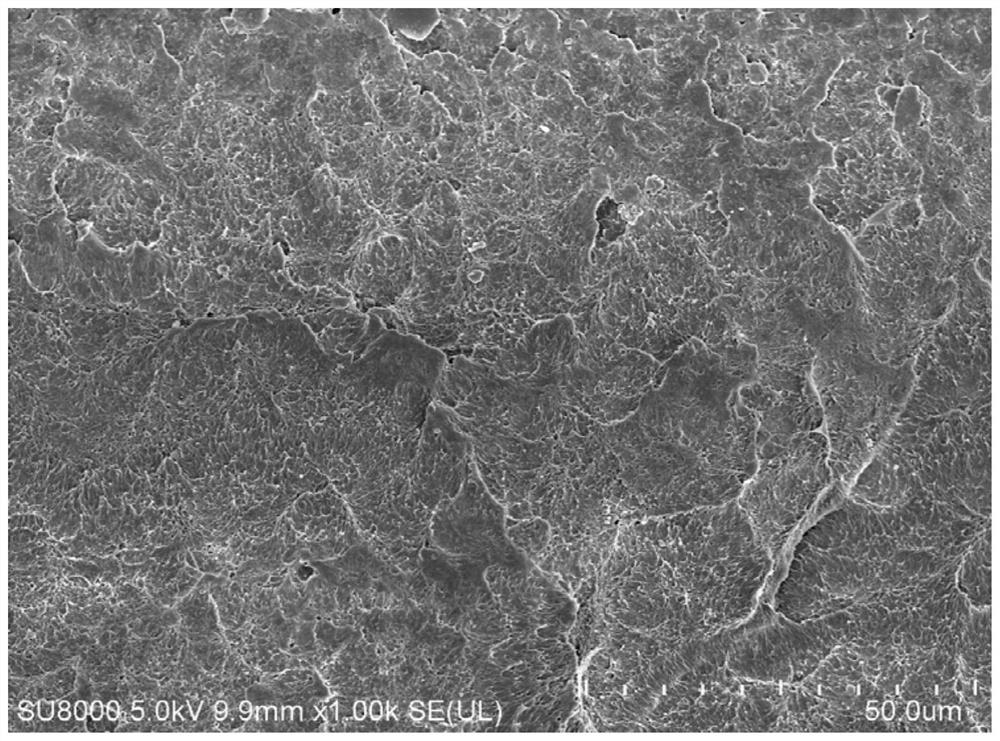

[0042] (3) Physically mix X-ECTFE obtained in step (1), suspension A and suspension B obtained in step (2), and add dispersant ethanol, wherein chlorotrifluoroethylene homopolymer, chlorotrifluoroethylene The mass ratio of copolymer and X-ECTFE is 87:12:1;

[0043] (4) filtering, washing and drying the mixed solution obtained in step (3) to finally obtain a mixed powder;

[0044](5) The mixed powder obtained in step (4) is passed through a molding machine to make corresponding test samples, ...

Embodiment 3

[0046] (1) with step (1) in embodiment 2;

[0047] (2) with step (2) in embodiment 2;

[0048] (3) Physically mix X-ECTFE obtained in step (1), suspension A and suspension B obtained in step (2), and add dispersant ethanol, wherein chlorotrifluoroethylene homopolymer, chlorotrifluoroethylene The mass ratio of copolymer and X-ECTFE is 94:5:1;

[0049] (4) with step (4) in embodiment 2;

[0050] (5) With step (5) in embodiment 2. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com