A kind of aluminum sheet used for frame in neutron detector and its preparation process

A neutron detector and preparation process technology, applied in the measurement of neutron radiation, the improvement of process efficiency, the coating process of metal materials, etc. slag and other problems, to achieve the effect of uniform internal structure without slag inclusion, reducing pollution and reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

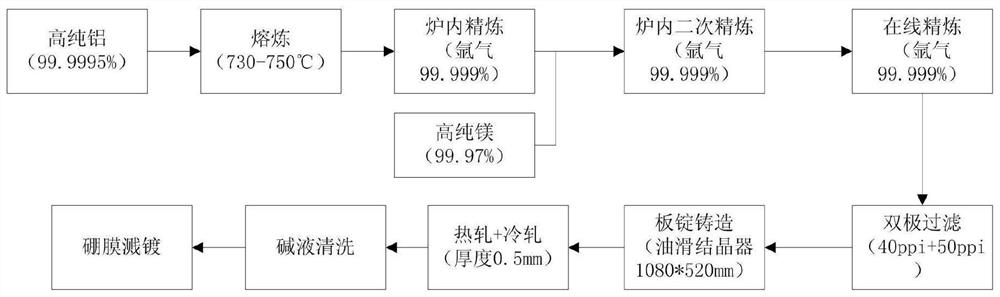

[0056] A preparation process of an aluminum sheet for a frame in a neutron detector, comprising the following steps:

[0057] (1) After the high-purity aluminum ingot is completely melted, it is refined once with high-purity argon to obtain melt 1;

[0058] (2) Add high-purity magnesium ingots to the melt 1, and after complete melting, melt 2 is obtained;

[0059] (3) The melt 2 is subjected to secondary refining with high-purity argon, and the slag is removed to obtain the melt 3;

[0060] (4) The melt 3 adopts high-purity argon to carry out on-line refining to obtain the melt 4;

[0061] (5) The melt 4 adopts high-purity argon to carry out double-stage plate filtration to obtain the melt 5;

[0062] (6) Casting: Casting under the protection of inert gas to obtain flat ingots;

[0063] (7) After milling the surface of the flat ingot, it is processed by hot rolling and cold rolling to obtain foil;

[0064] (8) Cleaning the foil for four passes to obtain the aluminum sheet ...

Embodiment 1

[0080] Process flow chart such as figure 1 As shown, the specific operation steps are as follows:

[0081] (1) Ultra-pure raw materials: use high-purity aluminum raw materials with a purity of more than 99.9995 wt%, wherein U+Th≤1ppb. High-purity magnesium ingot with a purity of 99.97%, where U+Th≤1ppb.

[0082] (2) Melting: High-purity aluminum raw materials are added to an intermediate frequency induction melting furnace to heat up and melt. The lining of the intermediate frequency melting furnace is made of refractory materials, and the content of alumina in the refractory materials is controlled to be ≥ 90%, so as to avoid the pollution of the lining to the molten aluminum during the melting process.

[0083] (3) Primary refining in the furnace: After the molten aluminum is completely melted, the temperature of the molten aluminum is controlled at 730-750°C, and argon gas with a purity of 99.999% is passed through the furnace for primary refining. Control the argon gas ...

Embodiment 2

[0095] The specific operation steps are as follows:

[0096] (1) Al in refractory materials for lining of intermediate frequency melting furnace 2 o 3 The proportion is 92.5%. Add 6 tons of high-purity aluminum ingots to the intermediate frequency melting furnace for molten aluminum melting. The purity of high-purity aluminum ingot is 99.9995%, among which U is 0.00012ppm and Th is 0.00036ppm.

[0097] (2) After the high-purity aluminum ingot is completely melted, use a thermocouple to measure the temperature, and control the temperature of the molten aluminum to 730-750°C to start the primary refining in the furnace. A high-purity argon gas is passed through the furnace for primary refining. Control the argon gas flow to 4.0Nm 3 / h, the refining time is 15min, and after the refining is finished, use a high-purity graphite spoon to salvage the scum on the surface of the molten aluminum.

[0098] (3) Add magnesium ingots after refining. The purity of magnesium ingot is 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com