Machine table for depositing high-adhesion film on III-V substrate and a process of machine table

A III-V, high-adhesion technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of reduced adhesion, poor film adhesion, oxygen isolation, etc., to achieve guaranteed Clean, hydrogen-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

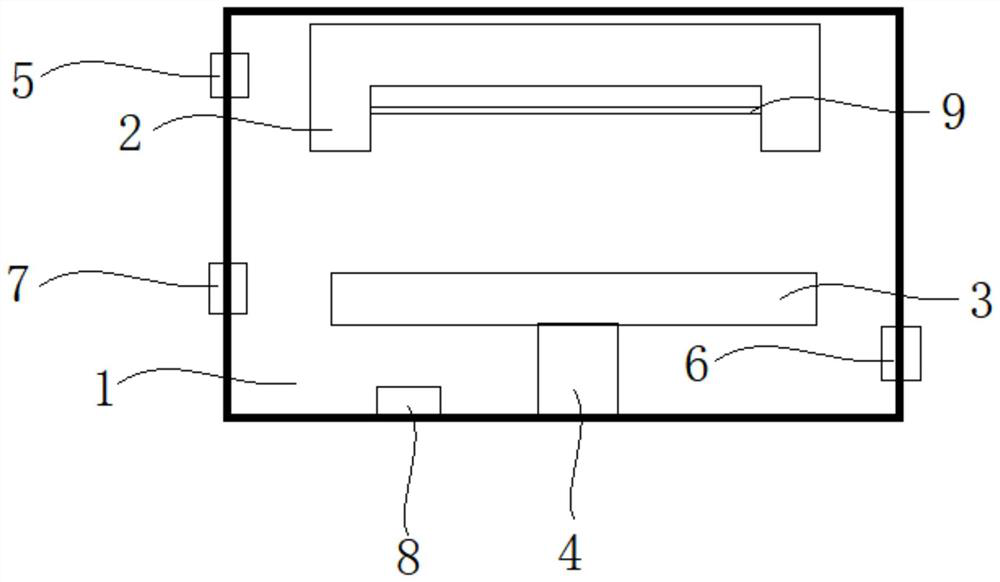

[0043] figure 1 As shown, the machine platform for depositing a high-adhesive film on a III-V substrate provided by the present application includes a main chamber 1, a support base 2 is arranged on the top of the main chamber 1, and a lifting device is installed at the bottom of the main chamber 1 4. The lifting device 4 is arranged opposite to the support base 2, and the slide table 3 is installed at the position where the lifting device 4 is opposite to the support base 2; the aforementioned support base 2 is U-shaped, and a catalytic wire is embedded in the U-shaped groove 9. The catalytic wire 9 is a tungsten wire or a graphite wire; one side of the main chamber 1 is respectively provided with a first air inlet 5 and an air inlet 7, wherein the first air inlet 5 is used to feed reaction gas, and the air inlet 7 is connected to the The molecular pump and the dry pump are connected in sequence. Usually, the dry pump and the molecular pump are used as follows. It is the bac...

Embodiment 2

[0050] This application provides a process for depositing a high-adhesion film on a III-V substrate, including a film deposition process and a cleaning process,

[0051] The thin film deposition process includes

[0052] In step 11, the lifting device 4 is started, and the loading table 3 is lowered by the lifting device 4, so that the loading table 3 is far away from the support base 2, and the III-V sample is placed on the loading table 3,

[0053]Step 12, close the main chamber 1, turn on the dry pump and the molecular pump successively, and evacuate the main chamber 1 until the internal pressure of the main chamber 1 is lower than 1mTorr. Oxygen desorption prevents tungsten wire or graphite wire from being oxidized, thus increasing the service life. The temperature of the slide table 3 is kept at 350 °C

[0054] Step 13, feed hydrogen and ammonia into the main chamber 1 through the first air inlet 5, the flow range of the hydrogen feed is 10-200 sccm, and the flow range o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap