Preparation method of silicon carbide single crystal with low microtube density and silicon carbide single crystal

A technology of density silicon carbide and silicon carbide, applied in the field of silicon carbide crystal preparation, can solve problems affecting crystal quality, damaging the yield and reliability of semiconductor devices, and achieving the effect of low micropipe density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments.

[0024] Embodiments of the present invention firstly provide a method for preparing a silicon carbide single crystal with low micropipe density.

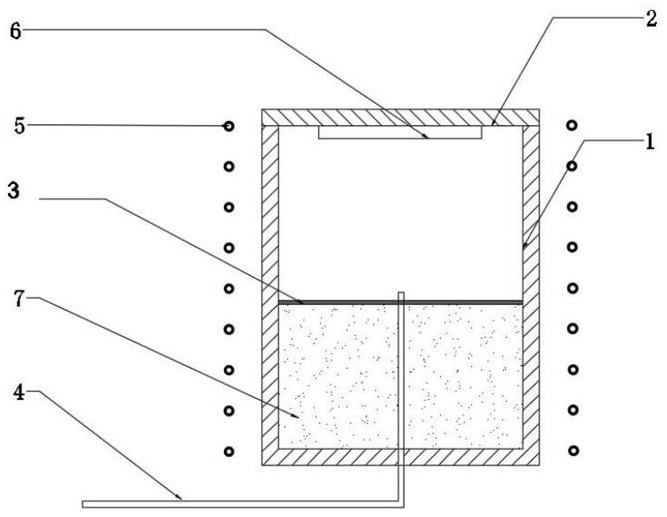

[0025] Please refer to figure 1 , is a cross-sectional view of a silicon carbide single crystal device with a low micropipe density prepared by using a method for preparing a silicon carbide single crystal with a low micropipe density according to an embodiment of the present invention.

[0026] In step 1, first put the crucible containing silicon carbide powder and assembled silicon carbide seed crystal into the crystal growth furnace and evacuate and depressurize the furnace. Inject protective gas to adjust the pressure and raise the temperature at the same time.

[0027] like figure 1 As shown, before forming the thermal gradient, a certain amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com