Flexible positive electrode material of lithium-sulfur battery and preparation method of flexible positive electrode material

A positive electrode material, lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, positive electrodes, etc., can solve difficult and difficult to realize industrialization and other problems, and achieve the effect of improving kinetic behavior, low price, and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

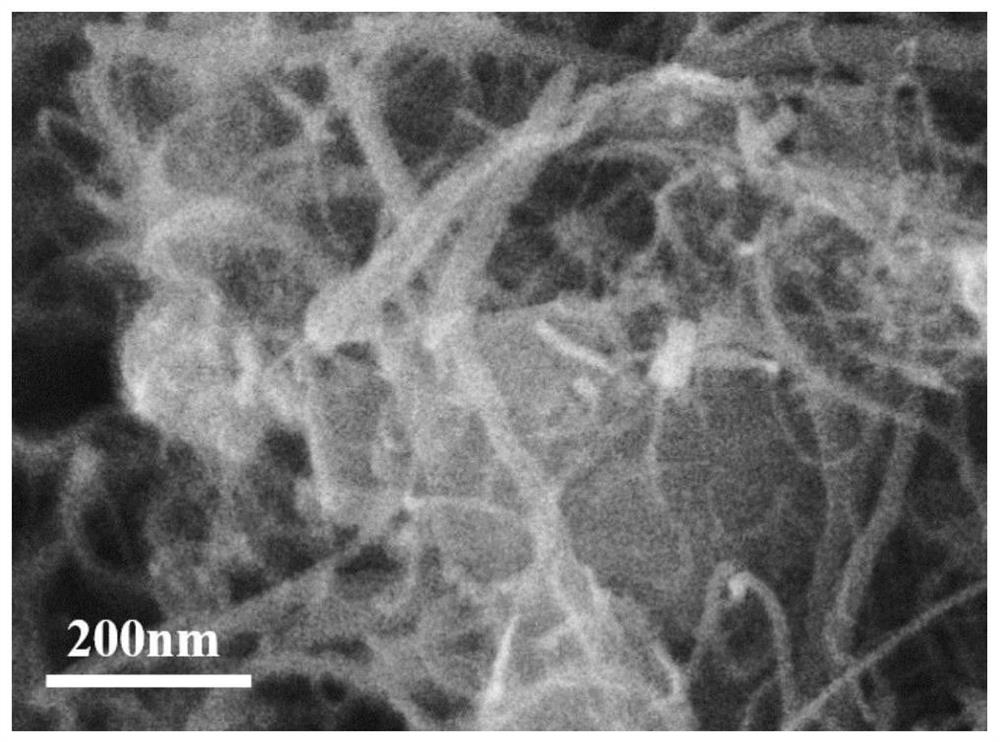

Image

Examples

Embodiment 1

[0057] The preparation method of the lithium-sulfur battery flexible positive electrode material in this embodiment includes the following steps:

[0058] (1)C 3 N 4 Solution preparation: the C 3 N 4 Grind, sieve 100 mesh, then soak in sulfuric acid, then move to a water bath and heat to 80°C until the solution is clear, and prepare C 3 N 4 0.1wt% solution;

[0059] (2) Preparation of graphene oxide solution: raw material is flake graphite, adopts improved Hummers method, graphite is oxidized, washed to neutral with deionized water, ultrasonically treated for 4h, prepared into a solution of 0.5wt% graphene;

[0060] (3) Preparation of oxidized carbon nanotube solution: raw material is multi-walled carbon nanotube, adopts improved Hummers method, carbon nanotube is oxidized, washes to neutrality with deionized water, is mixed with oxidized carbon nanotube 0.1wt% solution;

[0061] (4) Preparation of ion-loaded few-layer bentonite material: immerse bentonite in deionized ...

Embodiment 2

[0066] The preparation method of the lithium-sulfur battery flexible positive electrode material in this embodiment includes the following steps:

[0067] (1)C 3 N 3 Solution preparation: the C 3 N 3 Grind, sieve 100 mesh, then soak in 5wt% sulfuric acid solution and then move to a water bath at 95°C until the solution is clarified and prepared into C 3 N 3 0.1wt% solution;

[0068] (2) Preparation of graphene oxide solution: raw material is flake graphite, adopts improved Hummers method, graphite is oxidized, washed to neutrality with deionized water, ultrasonically treated for 6h, and prepared into a solution of 1wt% graphene;

[0069] (3) Preparation of oxidized carbon nanotube solution: raw material is multi-walled carbon nanotube, adopts improved Hummers method, carbon nanotube is oxidized, is mixed with the solution of 0.5wt% oxidized carbon nanotube with deionized water to neutrality ;

[0070] (4) Preparation of few-layer attapulgite material: immerse attapulgit...

Embodiment 3

[0075] The preparation method of the lithium-sulfur battery flexible positive electrode material in this embodiment includes the following steps:

[0076] (1)C 2 The preparation of N: the C 2 N is ground, sieved with 300 mesh, then soaked in 5wt% phosphoric acid solution, and then moved to a water bath at 100°C until the solution is clear, and is prepared as C 2 N is a 4wt% solution;

[0077] (2) Preparation of graphene oxide solution: raw material is flake graphite, adopts improved Hummers method, graphite is oxidized, washed to neutrality with deionized water, ultrasonically treated for 12h, and prepared into a solution of 1wt% graphene;

[0078] (3) Preparation of oxidized carbon nanotube solution: raw material is single-walled carbon nanotube, adopts improved Hummers method, carbon nanotube is oxidized, washes to neutrality with deionized water and is mixed with the solution of 0.5wt% oxidized carbon nanotube ;

[0079] (4) Preparation of the few-layer hydrotalcite mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com