Ruthenium-zirconium composite alkylation catalyst and preparation method thereof

A technology of compound alkyl and catalyst, applied in the field of alkyl anthracene compounds, can solve the problems of large proportion of di-substituted alkyl anthracene, low selectivity of 2-alkyl anthracene, serious equipment corrosion, etc., and achieve stable catalytic performance, alkyl anthracene The effect of high catalytic activity and selectivity, and overall acidity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

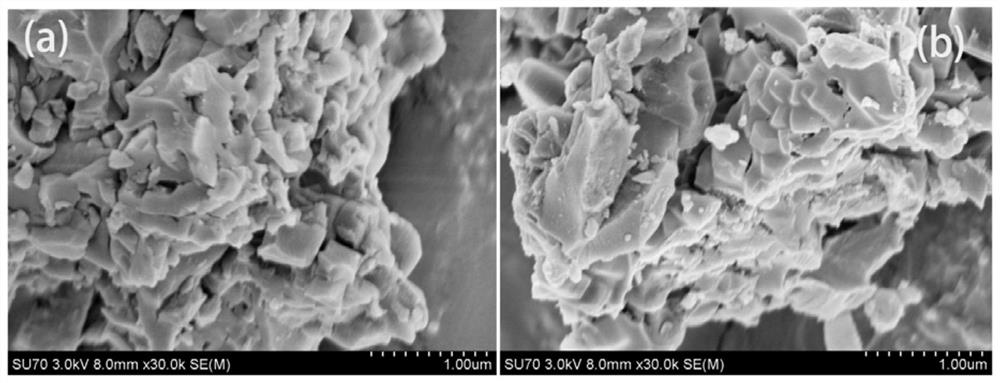

Image

Examples

Embodiment 1

[0030] The first step of catalyst preparation: 4.12g of zirconium nitrate pentahydrate and 2.22g of citric acid were added to 60mL of deionized water at room temperature, stirred, and then 4g of MOR molecular sieves were added. Stirring was continued for 2h, and then the water was evaporated at 80°C, dried at 100°C for 24h, ground, and calcined at 500°C for 10h to prepare a citric acid-modified Zr-MOR (S1-0) molecular sieve catalyst. Add 113mg ruthenium trichloride hydrate and 115mg citric acid into 30mL deionized water at room temperature, stir, then add 2g (S1-0), continue stirring for 2h, then evaporate the water at 80°C, and dry at 100°C for 24h. Grinding and calcining at 500° C. for 10 h to prepare a ruthenium-zirconium composite alkylation catalyst (S1).

[0031] The second step of catalytic alkylation reaction: Take the S1 molecular sieve catalyst (30wt%, 300mg) and anthracene (1.0g) obtained in the first step, add 8mL of mesitylene as a solvent, and then add tert-amyl ...

Embodiment 2

[0039] The first step of catalyst preparation: add 1.03g of zirconium nitrate pentahydrate and 0.36g of tartaric acid into 30mL of deionized water at room temperature, stir, and then add 2g of all-silicon β molecular sieve. Stirring was continued for 2 hours, and then the water was evaporated at 80°C, dried at 100°C for 12 hours, ground, and calcined at 500°C for 10 hours to prepare a tartaric acid-modified 12wt% Zr-all-silicon β(S2-0) catalyst. Add 113mg ruthenium trichloride hydrate and 75mg tartaric acid into 30mL deionized water at room temperature, stir, then add 2g (S1-0), continue stirring for 2h, then evaporate the water at 80°C, dry at 100°C for 24h, grind , Calcined at 500° C. for 10 h to prepare a ruthenium-zirconium composite alkylation catalyst (S2).

[0040] The second step catalytic alkylation reaction: get S2 catalyst (30wt%, 300mg) and anthracene (1.0g) obtained in the first step, add 8mL mesitylene as solvent, then add tert-amyl alcohol (1.1eq, 0.55g) as For...

Embodiment 3

[0042] The first step of catalyst preparation: 4.12g of zirconium nitrate pentahydrate and 2.22g of citric acid were added to 60mL of deionized water at room temperature, stirred, and then 4g of MOR molecular sieves were added. Stirring was continued for 2h, and then the water was evaporated at 80°C, dried at 100°C for 24h, ground, and calcined at 500°C for 10h to prepare a citric acid-modified Zr-MOR (S1-0) molecular sieve catalyst. Add 225 mg of ruthenium trichloride hydrate and 230 mg of citric acid into 30 mL of deionized water at room temperature, stir, then add 2 g of (S1-0), continue stirring for 2 h, then evaporate the water to dryness at 80 ° C, and dry at 100 ° C for 24 h. Grinding and calcining at 500° C. for 10 h to prepare a ruthenium-zirconium composite alkylation catalyst (S3).

[0043] The second step of catalytic alkylation reaction: take the S3 molecular sieve catalyst obtained in the first step (30wt%, 300mg) and anthracene (1.0g), add 8mL of mesitylene as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com