Method for denitrifying light oil

A light oil and denitrification technology, applied in the chemical field, can solve air pollution and other problems, and achieve the effects of no secondary pollution, mild reaction conditions and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

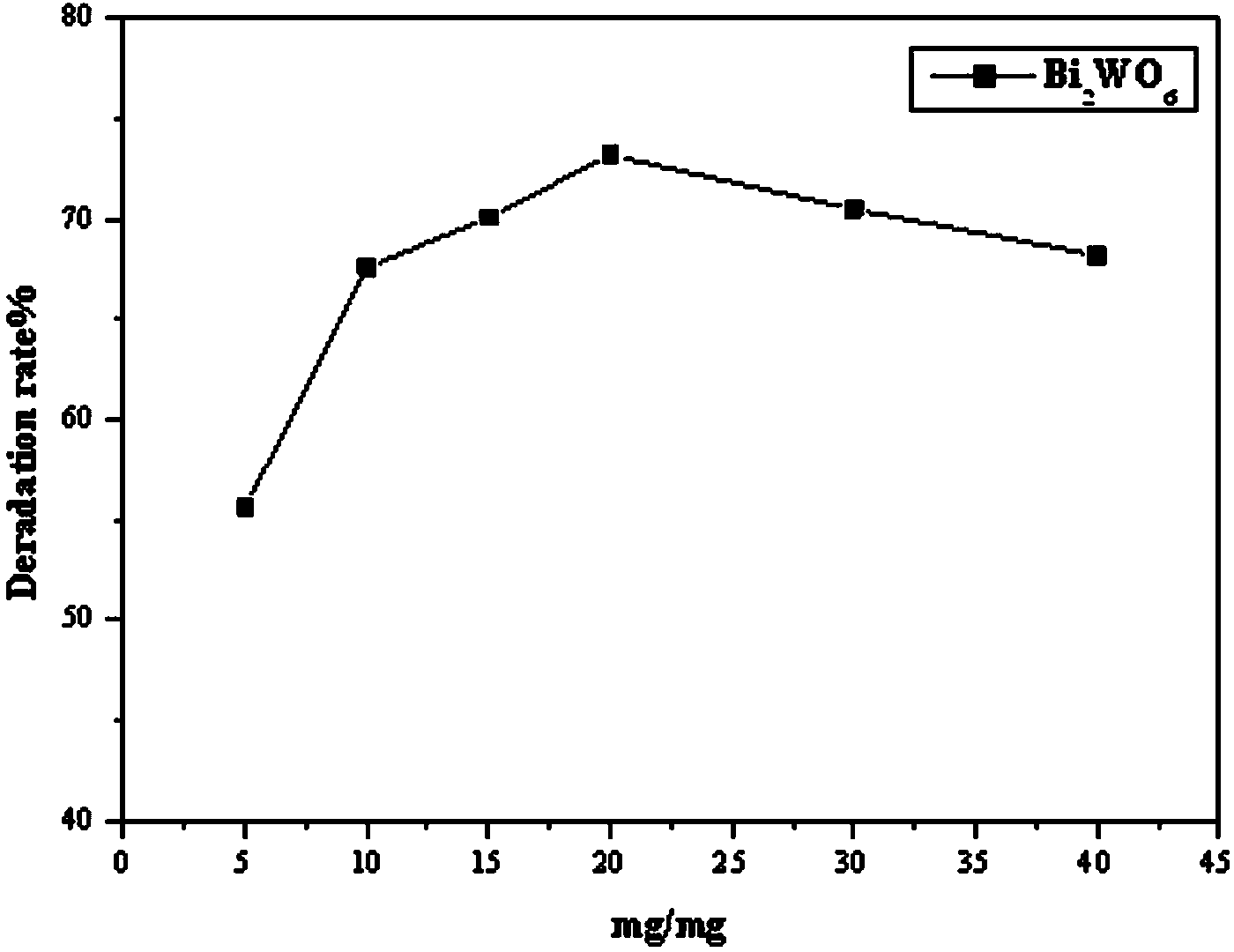

[0021] Take a certain amount of photocatalyst, add it to nitrogen-containing light oil, control agent oil ratio: 20mg: 5ml, turn on the xenon lamp device in the photocatalytic reaction box, control the reaction speed within the range of 300r / min, and the reaction temperature at Within the range of 20°C, control the photocatalyst reaction for 3 hours; the photocatalyst is: Bi 2 WO 6 ;

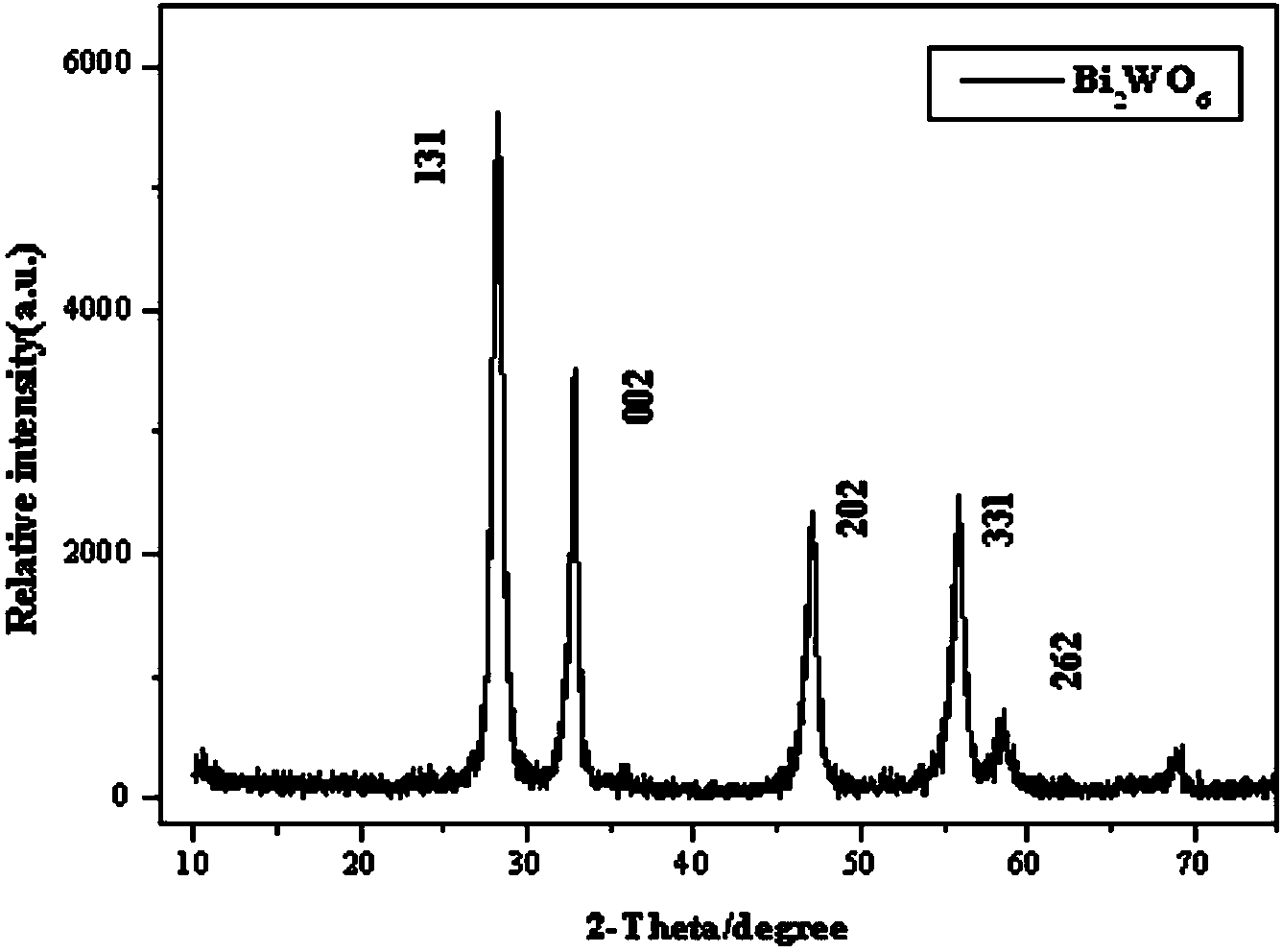

[0022] The photocatalyst Bi 2 WO 6 , is a self-made catalyst, and its preparation method is: with Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O is used as a raw material, and it is dissolved in a nitric acid solution with a concentration of 2 mol / L to obtain a precursor solution, which is then transferred to a reaction kettle. Filter it, wash it with deionized water until the Ph value is 7; control the drying temperature within the range of 60°C, and dry it for 4 hours to obtain the required photocatalyst Bi 2 WO 6 ; The Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 The mol ratio of O is: 2...

Embodiment 2

[0024] Take a certain amount of photocatalyst, add it to nitrogen-containing light oil, control agent oil ratio: 5mg: 5ml, turn on the xenon lamp device in the photocatalytic reaction box, control the reaction speed in the range of 100~400r / min, the reaction temperature Control the photocatalyst reaction within 15°C for 3 hours; the photocatalyst is: Bi 2 WO 6 ;

[0025] The photocatalyst Bi 2 WO 6 , is a self-made catalyst, and its preparation method is: with Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O is used as a raw material, and it is dissolved in a non-aqueous nitric acid solvent with a concentration of 4 mol / L to obtain a precursor solution, which is then transferred to a reaction kettle, and the hydrothermal synthesis temperature is controlled within the range of 120 °C, and the hydrothermal synthesis reaction is carried out for 20 h. After the reaction, filter it and wash it with absolute ethanol until the Ph value is 7; control the drying temperature in the ran...

Embodiment 3

[0027] Take a certain amount of photocatalyst, add it to nitrogen-containing light oil, control agent oil ratio: 30mg: 10ml, turn on the xenon lamp device in the photocatalytic reaction box, control the reaction speed within the range of 300r / min, and the reaction temperature at Within the range of 25°C, control the photocatalyst reaction for 5 hours; the photocatalyst is: Bi 2 WO 6 ;

[0028] The photocatalyst Bi 2 WO 6 , is a self-made catalyst, and its preparation method is: with Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O is used as a raw material, and it is dissolved in nitric acid with a concentration of 3 mol / L to obtain a precursor solution, which is then transferred to a reaction kettle, and the hydrothermal synthesis temperature is controlled within the range of 180 °C, and the hydrothermal synthesis reaction is carried out for 26 hours. It is filtered and washed with absolute ethanol until the Ph value is 7; the drying temperature is controlled within the rang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com