Preparation method of anisotropic hydrogel

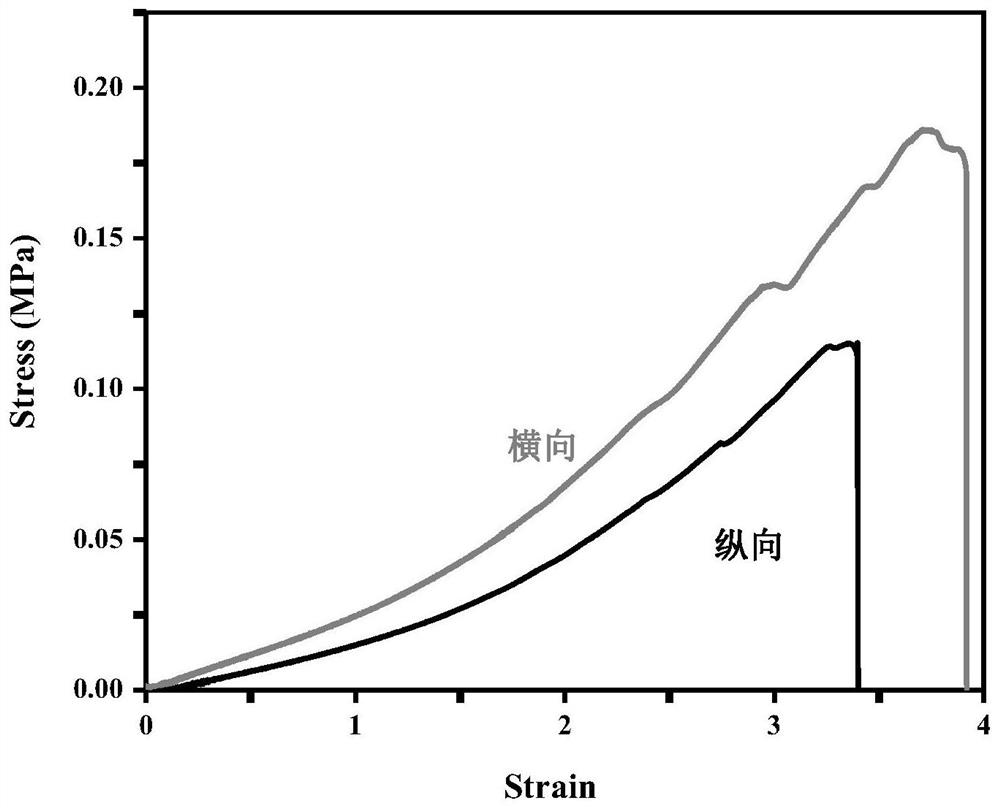

An anisotropic, hydrogel technology, applied in the field of multifunctional hydrogel preparation, can solve the problems of limited application of hydrogel, lack of ordered structure, etc., and achieve the effect of good biocompatibility, high strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A kind of preparation method of anisotropic hydrogel of the present invention, specifically implement according to the following steps:

[0025] Step 1, mixing gelatin with deionized water, putting it into a constant temperature oscillator for reaction, making it fully dissolved, and obtaining a gelatin solution;

[0026] The mass ratio of gelatin to deionized water is 0.1-4:2-5;

[0027] The reaction temperature is 30-100°C, and the reaction time is 10-120min;

[0028] Step 2, the photoinitiator is dissolved in deionized water to obtain a photoinitiator solution;

[0029] The photoinitiator is diphenylacetone BP, 4-diethylthioxanthone or 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone;

[0030] The mass ratio of photoinitiator to deionized water is 0.0001-1:1-10;

[0031] Step 3, mix the N-isopropylmethacrylamide monomer with deionized water, place it in an ultrasonic shaker to dissolve it, add the crosslinking agent N,N-methylenebisacrylamide after dissolution...

Embodiment 1

[0039] A kind of preparation method of anisotropic hydrogel of the present invention, specifically implement according to the following steps:

[0040] Preliminary preparation: Weigh 1.5g of gelatin into a beaker and dissolve in 3.5mL of deionized water at 40°C for 30 minutes. Then take 10mL of deionized water and stir and dissolve 0.005g of photoinitiator in a glass cup for later use.

[0041] Material treatment: Accurately weigh 0.2g of monomer NIPMAM, add 3mL of deionized water, and place it in an ultrasonic shaker to dissolve for 20min. The mixture solution was poured into the gelatin solution, and stirred slowly for 3 minutes to make it fully mixed.

[0042] Photolithography reaction: Finally, weigh 0.0075g of TG enzyme and dissolve it in 1mL of deionized water, add the enzyme solution dropwise to the mixture until the mixture is completely dissolved and there are basically no more bubbles, then pour it into the mold, and then clamp it on the quartz plate Put the two en...

Embodiment 2

[0044] A kind of preparation method of anisotropic hydrogel of the present invention, specifically implement according to the following steps:

[0045] Preliminary preparation: Weigh 2g of gelatin into a beaker, take 4mL of deionized water and dissolve it at 45°C for 35 minutes. Then take 10mL of deionized water and stir and dissolve 0.01g of photoinitiator in a glass cup for later use.

[0046] Material treatment: Accurately weigh 0.1g of monomer NIPMAM, add 3mL of deionized water, place it in an ultrasonic shaker to dissolve for 40min, add 0.028g of crosslinking agent MBAA after dissolution, and finally add 1mL of photoinitiator solution, mix well; The mixture solution was poured into the gelatin solution, and stirred slowly for 5 minutes to make it fully mixed.

[0047] Photolithography reaction: Finally, weigh 0.01g of TG enzyme and dissolve it in 1mL of deionized water, add the enzyme solution dropwise to the mixture until the mixture is completely dissolved and there ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com