High-temperature-resistant silica gel for high-temperature roller and preparation method thereof

A high temperature resistant and high temperature resistant filler technology, applied in the field of silicone products, can solve the problems of thermal aging, loss of elasticity and strength, and degradation of silicone products, and achieve the effect of improving high temperature aging resistance, tight and uniform bonding, and increasing structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

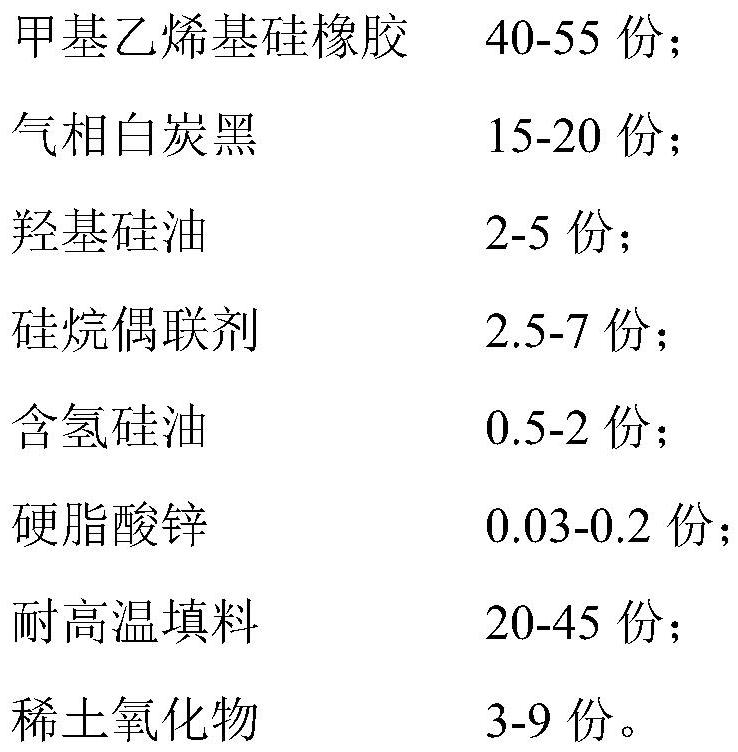

[0023] The parts by weight of the high-temperature-resistant silica gel raw materials in Examples 1-5 are shown in Table 1.

[0024] Parts by weight of high temperature resistant silica gel raw materials in Table 1 Examples 1-5

[0025]

[0026] Used in the embodiment 1-5, the vinyl content in the methyl vinyl silicone rubber is 0.05-2%; The specific surface area of the fumed silica is 150-400m 2 / g; the hydroxyl content in hydroxy silicone oil is 4-8%; the hydrogen content in hydrogen-containing silicone oil is 1.2-1.6%; the mesh number of diatomaceous earth is 1000-5000 mesh; the mesh number of spherical aluminum hydroxide is 1000-10000 mesh; the specific surface area of cerium oxide is 20-200m 2 / g; the specific surface area of praseodymium oxide is 20-200m 2 / g.

[0027] In Example 1-5, the preparation method of high temperature resistant silica gel comprises the following steps: put methyl vinyl silicone rubber, hydroxyl silicone oil, silane coupling agent and...

Embodiment 6-10

[0029] The parts by weight of high-temperature-resistant silica gel raw materials in Examples 6-10 are shown in Table 2.

[0030] Parts by weight of high temperature resistant silica gel raw materials in Table 2 Examples 6-10

[0031]

[0032] Used in the embodiment 6-10, the vinyl content in the methyl vinyl silicone rubber is 0.05-2%; The specific surface area of the fumed silica is 150-400m 2 / g; the hydroxyl content in hydroxy silicone oil is 4-8%; the hydrogen content in hydrogen-containing silicone oil is 1.2-1.6%; the mesh number of diatomaceous earth is 1000-5000 mesh; the mesh number of spherical aluminum hydroxide is 1000-10000 mesh; the specific surface area of cerium oxide is 20-200m 2 / g; the specific surface area of praseodymium oxide is 20-200m 2 / g.

[0033] In Examples 6-10, the preparation method of high temperature resistant silica gel comprises the following steps: put methyl vinyl silicone rubber, hydroxyl silicone oil, silane coupling agent an...

Embodiment 11-15

[0035] The parts by weight of the high temperature resistant silica gel raw materials in Examples 11-15 are shown in Table 3.

[0036] Table 3 Parts by weight of high temperature resistant silica gel raw materials in Examples 11-15

[0037]

[0038] Used in the embodiment 11-15, the vinyl content in the methyl vinyl silicone rubber is 0.05-2%; The specific surface area of the fumed silica is 150-400m 2 / g; the hydroxyl content in hydroxy silicone oil is 4-8%; the hydrogen content in hydrogen-containing silicone oil is 1.2-1.6%; the mesh number of diatomaceous earth is 1000-5000 mesh; the mesh number of spherical aluminum hydroxide is 1000-10000 mesh; the specific surface area of cerium oxide is 20-200m 2 / g; the specific surface area of praseodymium oxide is 20-200m 2 / g.

[0039] In Examples 11-15, the preparation method of high-temperature resistant silica gel comprises the following steps: put methyl vinyl silicone rubber, hydroxyl silicone oil, silane coupling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com